Products & ReviewLab Automation

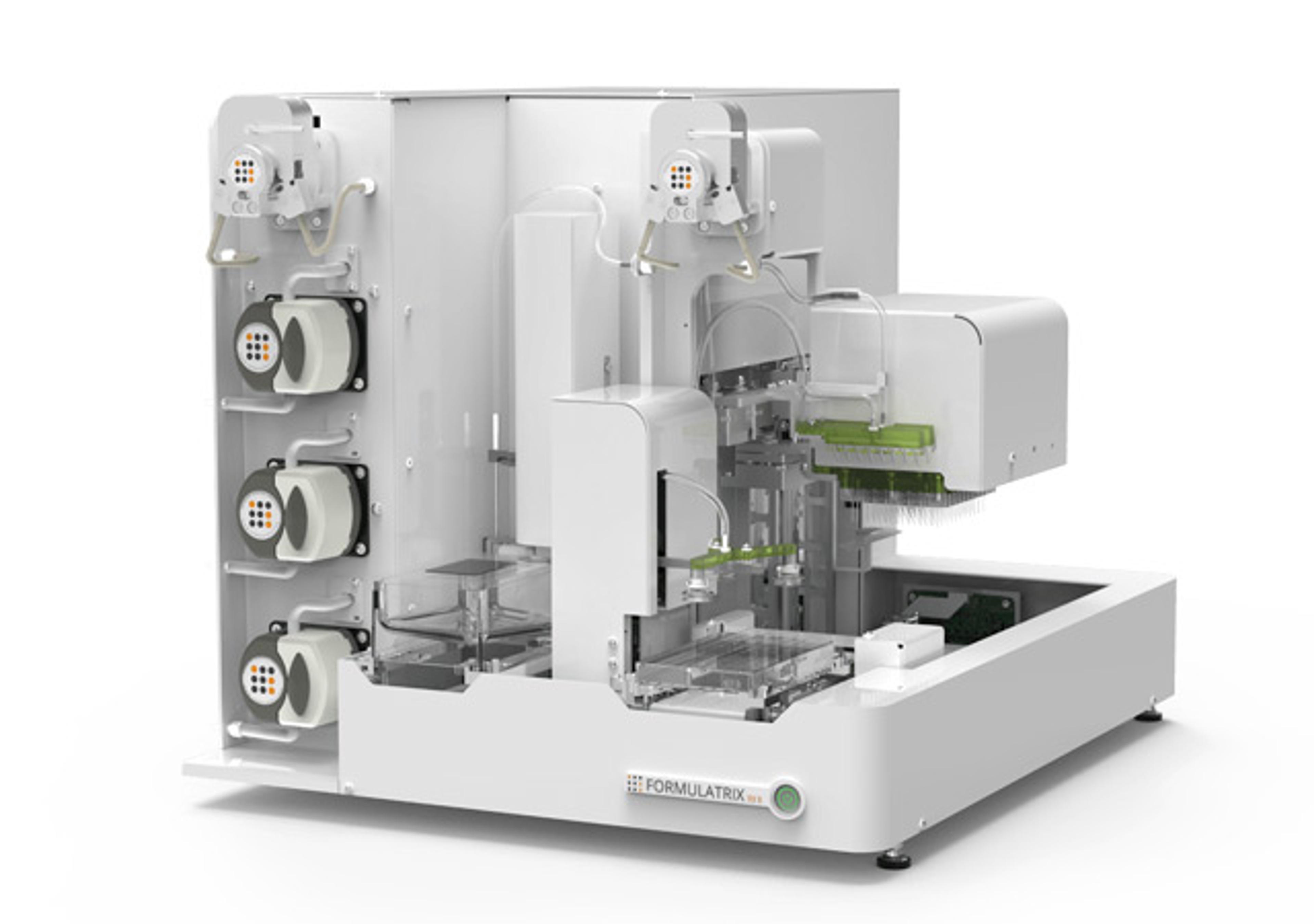

FluidX™ XDC-96

FluidX XDC-96 is a compact, standalone, high-speed whole rack tube de-capper and capper that automatically removes, recaps or disposes of septum caps from a full 96-format SBS rack of sample storage tubes; can also be integrated into automated sample storage and handling environments

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Features

- Using the XDC-96 systems for secure storage tube sealing, and eliminating the need for manual intervention, preserves sample integrity and audit trail in biobank, compound library and other high-throughput storage applications

- Broad compatibility and type of tube to be used with XDC-96 should be specified at time of ordering

- Recommended to be used with natural colored TPE septum caps

- Compatible with: FluidX 96-format tubes with septum caps (0.3ml, 0.48ml, 0.7ml, 0.9ml), Micronic Microtubes with Capcluster caps (0.65ml, 1.4ml), Matrix TrakMates with SepraSeal caps (0.5ml, 0.75ml, 1.4ml),Abgene Cypher with caps (0.65ml, 1.2ml)

- De-capping function eliminates the need to manually remove septum caps, dramatically improving productivity

- Septum piercing is no longer required, meaning a wider range of liquid handling systems can be considered for use on samples

- XDC-96 will dispose of the septum caps, or recap the same caps into the same tubes, manual recapping after sampling from tubes is no longer required

- Fast and easy to use: Cycle time for de-capping and recapping is 15-30 seconds, depending on tube type

- Simple to operate LCD touch screen, allowing set up, calibration and settings changes without PC connection

- Can be used in standalone mode, or can be integrated into automated systems easily by using the RS232 interface

- Windows-compatible maintenance and calibration software package provided with each unit

- Additional automation workflow features

- Purge module allows an inert gas of choice to be layered over the samples immediately after de-capping, and immediately before recapping

- Air blade feature prevents the waste chute from becoming blocked when caps are sent to disposal