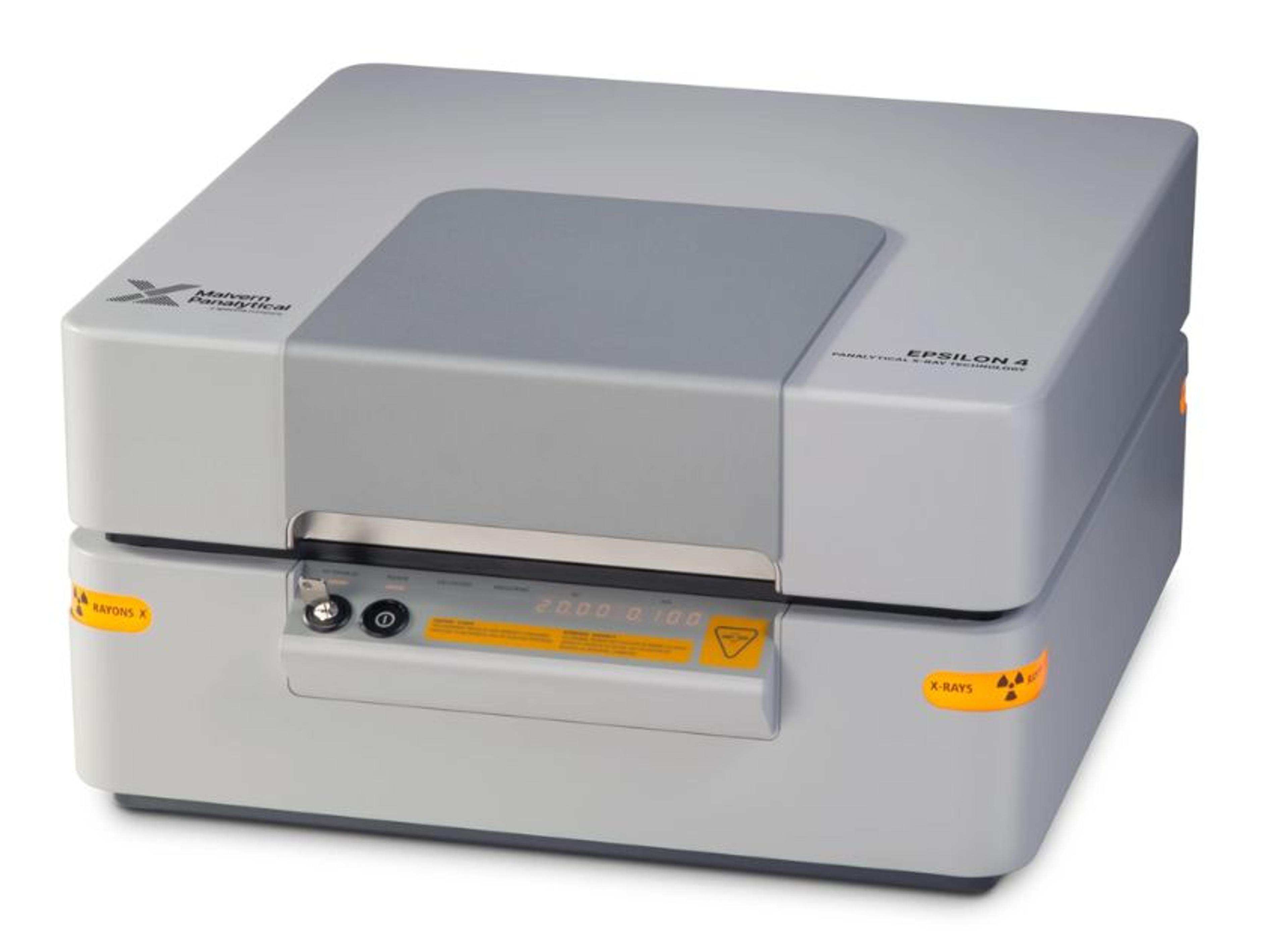

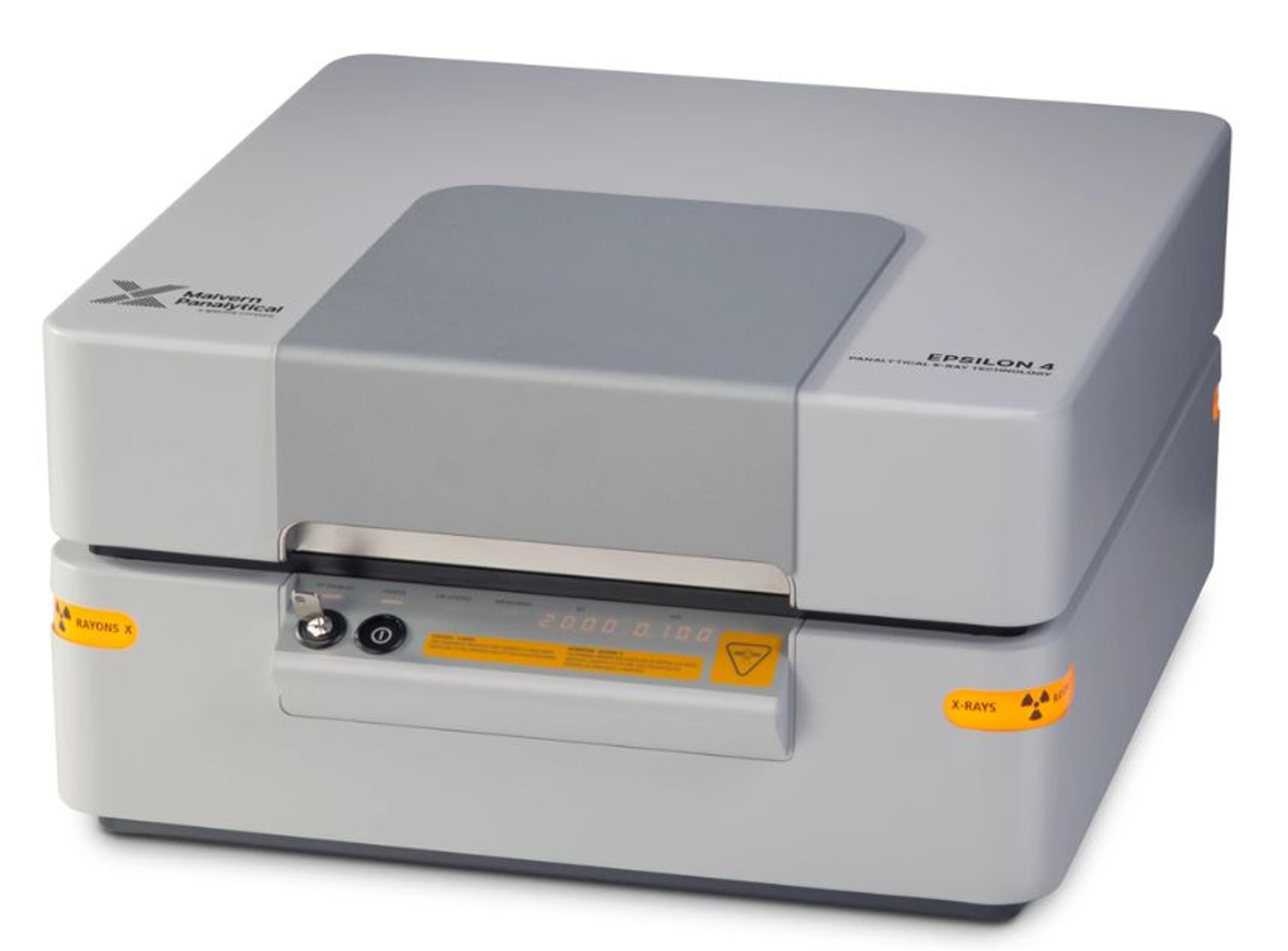

Epsilon 4 range

Fast and accurate at-line elemental analysis

Otímo equipamneto / Great equipment

Laboratório para analise manganês / Laboratory for manganese analysis

Já trabalhei com equipamento em outra empresa , ótimo equipamento estando bem calibrado, e indiquei para meu patrão a compra para trabalhar / I have already worked with equipment in another company, great equipment, well calibrated, and I recommended the purchase to my boss for work

Review Date: 28 Mar 2025 | Malvern Panalytical

Manufacturer's Response

Thank you for the review and the excellent scoring of Epsilon 4, for your application.

Good tool for fast screening and semi-quantitative application in waste industry.

Analyze various type of waste chemical, in solid, liquid and sludge form

After-sales service is efficient. Application engineer willing to help in troubleshooting. The result is reproducible as the machine has high consistency and stability. Easy to use for screening purposes.

Review Date: 25 Oct 2022 | Malvern Panalytical

Manufacturer's Response

Thank you for the nice review. It’s good to read that the Epsilon 4 gives value to your process, and that customer support provided the necessary trouble-shooting.

Time saving, with high quality results instrument.

analysis of environmental elemental pollutants

ED-XRF epsilon 4 is very effective and time saving instrument with high quality results for elemental analysis in environmental pollutant. it is also a user friendly operation of instrument of line aswell online.

Review Date: 6 Sept 2022 | Malvern Panalytical

Good instrument, fairly easy to use.

PGM analysis

The instrument works well and is quite easy to use. Setting up the analysis methods requires care, but is not too difficult. After analysis methods are ready, the instrument is easy to use. The omnian semi-quantitative analysis works surprisingly well without further calibration. The user interface is not very intuitive, but after a while, you get used to it. Good instrument, but the user interface could be better.

Review Date: 16 Dec 2021 | Malvern Panalytical

Manufacturer's Response

Thank you for your valued review and feedback on the instrument and method set-up. The software is a point of attention to us.

Can not think our QC lab without this instrument. High accuracy & friendly software

Cement application

I am really happy with the result and user friendly software. The life time of the instrument is very high. We are using a instrument from 10 year without having major problem. I am also happy with the support by their local agent and foreign expert either in remote or physical. During this covid situation, we have got the support from Spectris India. I wish to have a bright future for Malvern Panalytical and hope to buy our next product if opportunity.requirements come from management.

Review Date: 15 Dec 2021 | Malvern Panalytical

Manufacturer's Response

Thank you for your valued review. It is nice to read that the Epsilon 4 is easy to use and helps you in your analyses.

Highly accurate with an impressive software and design for elemental analysis.

Elemental analysis of research samples

I think this instrument is reliable and highly accurate for the detection of a wide range of elements in a variety of samples. Its impressive design and software help the researchers to interpret the results in a short period of time, which in turn saves the time which is required to determine the elements in any sample by other techniques like UV Visible Spectrophotometer or AAS. This technique doesn't involve any sample preparation step like digestion by acids which may lead to errors in the analysis. I highly recommend this equipment to other researchers.

Review Date: 31 May 2021 | Malvern Panalytical

Manufacturer's Response

Thank you for the nice feedback and confirmation that we as Malvern Panalytical are delivering the right solution for customers in the food industry that are looking for a more simple analytical method.

Great results and easy to use.

Application for cement, mining, education

The Epsilon 4 unit and program is simple and easy to use and maintain, and delivers reliable results. It consistently delivers results according to set standards.

Review Date: 20 May 2021 | Malvern Panalytical

Manufacturer's Response

Thank you for our feedback on the quality and usability of the Epsilon 4, for your application requirements.

Simple, produces reliable results, and eliminates traditionally used accessories.

Analysis of nickel ore.

The Epsilon 4 unit and program is simple and easy to use. It consistently delivers results according to set standards and the results are reproducible across different analysis methods (SAP, LIM, etc). Fewer accessories and materials involved (completely eliminates the use of vacuum pump and vacuum pump oil; prolene film is used on only one component and is changed less frequently). And one of the main reasons we decided to acquire this unit is because IT CAN BE TURNED OFF, therefore eliminating operating costs when the machine is not in use during the off-season. Support is accessible across various available media (text, call, e-mail, chat) and personnel is prompt and efficient in dealing with questions and/or clarifications. The initial cost is justifiable for the quality of the product. It’s compact (not oddly shaped!), easy to use and maintain, and delivers reliable results.

Review Date: 8 May 2021 | Malvern Panalytical

Manufacturer's Response

Thanks for sharing your positive feedback on the Epsilon 4 instrument, its usability, and the support you experience from the local Malvern Panalytical organization. That is highly appreciated.

Great instrument; could come with better instructions and post sales support.

Quantitative analysis of surface and bulk metals

We have used an Epsilon 3 for the purpose of quantifying surface metal concentration for a number of years. It is reliable and provides us with reproducible and accurate readings of metal concentration down as light as sodium. It also has a standardless bulk analysis routine (Omnian) that is useful for identifying and quantifying unknown materials. Based on the performance of the Epsilon 3 for R&D purposes, our company purchased an Epsilon 1 (replacing an old Portaspec XRF) for passivation measurement and galvalume pot analysis on one of our galvanizing lines. Once a routine is set up, it is relatively easy to use. However, the instructions that come with the XRF aren't very comprehensive. Getting help after the initial training session (which is better appreciated with a prior working knowledge of the instrument) isn't as simple as e-mailing an expert. I certainly would appreciate instructions/on-line courses specific to my needs.

Review Date: 19 Jan 2021 | Malvern Panalytical

Manufacturer's Response

Thank you for your review of the Epsilon 3 and Epsilon 1 instruments. I’m happy to read that both instruments deliver reliable and accurate readings for your metal applications. For some of the applications, the set-up can be difficult, and MalverPanalytical is always happy to provide expertise in setting up the applications for you. The online tutorial is a nice idea to consider.

Instrument with good performance for research and routine analysis.

Elemental analysis

Although the instrument can be used in a wide range of applications, we essentially use it for elemental analysis in filtered aerosl samples under thin sample conditions. For its proper use it is necessary to have a good knowledge of the physical processes of the analytical technique. Therefore, after some initial study, optimal performance can be obtained for the analysis of interest. Furthermore, the instrument is very stable and its performances remain constant for long periods so as to be suitable for routine use as well; Automatic performance checks are adequate to limit operator intervention after initial calibration.

Review Date: 16 Jan 2021 | Malvern Panalytical

Built on the experience and success of the proven Epsilon 3 range of XRF spectrometers, the Epsilon 4 is a multi-functional instrument for any industry segment needing elemental analysis from fluorine (F) to americium (Am) in areas from R&D through to process control. Combining the latest excitation and detection technologies with mature software and smart design, the analytical performance of Epsilon 4 approaches that of more powerful and floor-standing XRF spectrometers.

Due to its low infrastructural requirements, Epsilon 4 can be placed next to the production line anywhere in your process. Its high performance enables most applications to be operated at ambient conditions, reducing costs for helium or vacuum maintenance.

The Epsilon 4 handles a wide variety of sample types, including solids, pressed and loose powders, liquids and filters. It performs non-destructive quantitative analysis of elements from carbon (C) fluorine to americium (Am), in concentrations from 100% down to sub-ppm levels, on samples weighing anything from a few milligrams to kilograms.

The Epsilon 4 is a robust and reliable alternative to conventional systems for a wide variety of industries and applications, even when light element analysis is of outmost importance, including: cement production, mining, mineral beneficiation, iron, steel and non-ferrous metals, RoHS screening and quantification, petroleum and petrochemicals, polymers and related industries, glass production, forensics,

pharmaceuticals, healthcare products, environmental, food and cosmetics.