BioMicroLab XL tube and vial handlers

Reliable and affordable benchtop pick and place systems

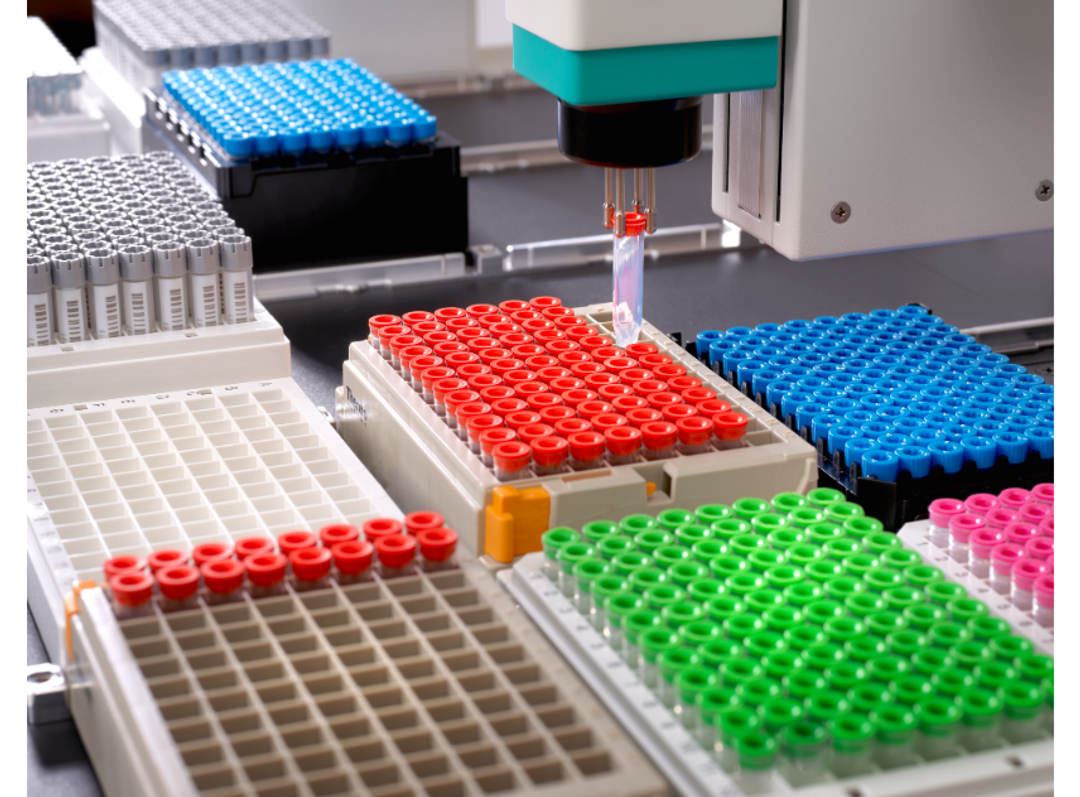

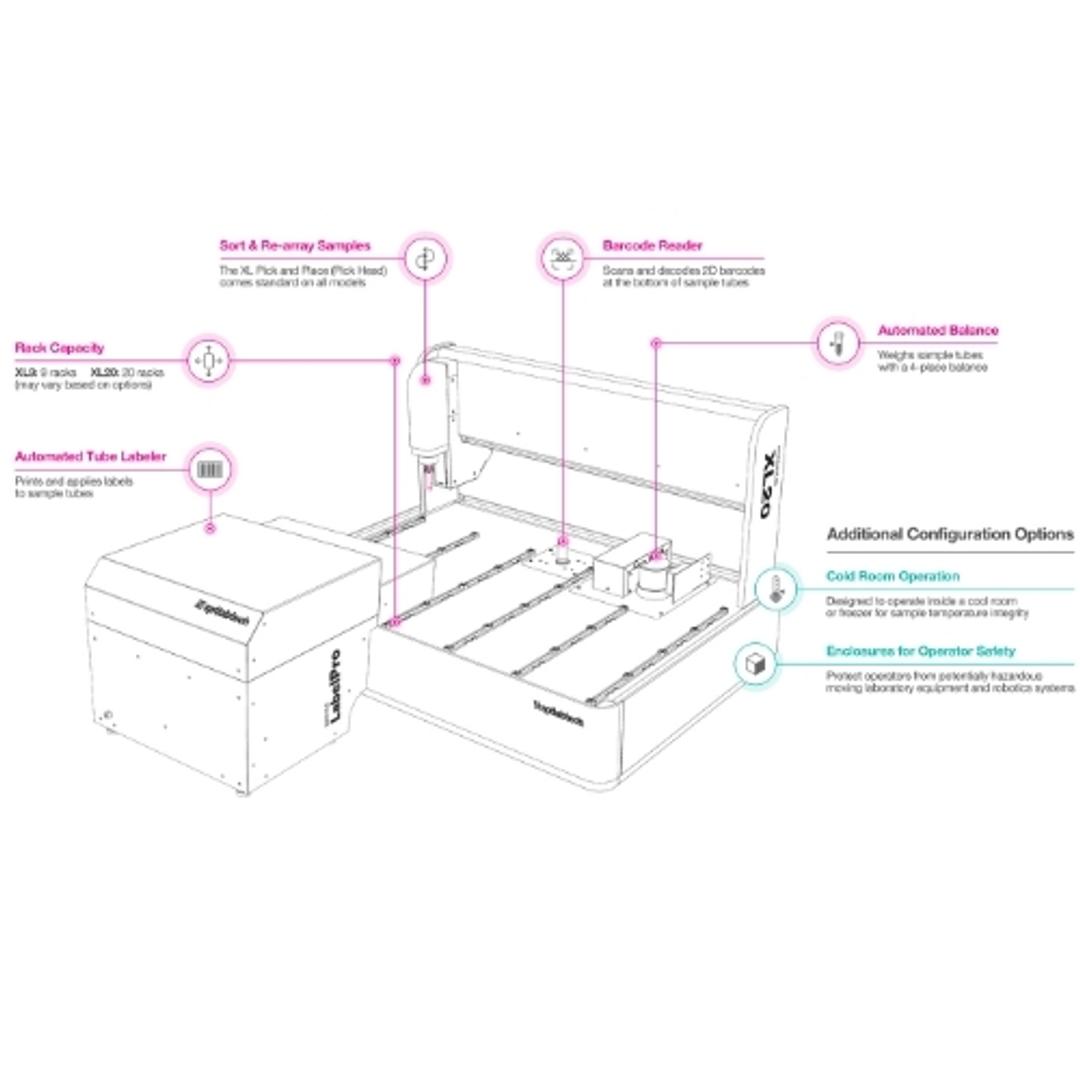

BioMicroLab XL automated tube and vial handling systems streamline critical sample management tasks such as organizing, reformatting and analyzing samples. There are four models varying by rack capacity and configurable modules, and each instrument can be used for a single operation in your workflow or to accomplish multiple tasks such as scanning, weighing and labeling. All models are fully electric (no compressed air needed) and include Windows-based user-friendly, integration-ready software and are fully compatible with LIMS systems.

XL9: The BioMicroLab XL9 tube handler for 96-format microtubes can be configured with labeling, sample tracking, and volume detection capabilities. With a 9 rack capacity, this is ideal for laboratories just starting out with automation or with limited benchtop space.

XL20: Like the XL9, the BioMicroLab XL20 tube handler for 96-format microtubes can be configured with labeling, sample tracking, and volume detection capabilities. With a larger deck holding 20 racks, the XL20 offers hours of “walk-away” time and is the ideal benchtop robot for use alongside fully automated sample stores.

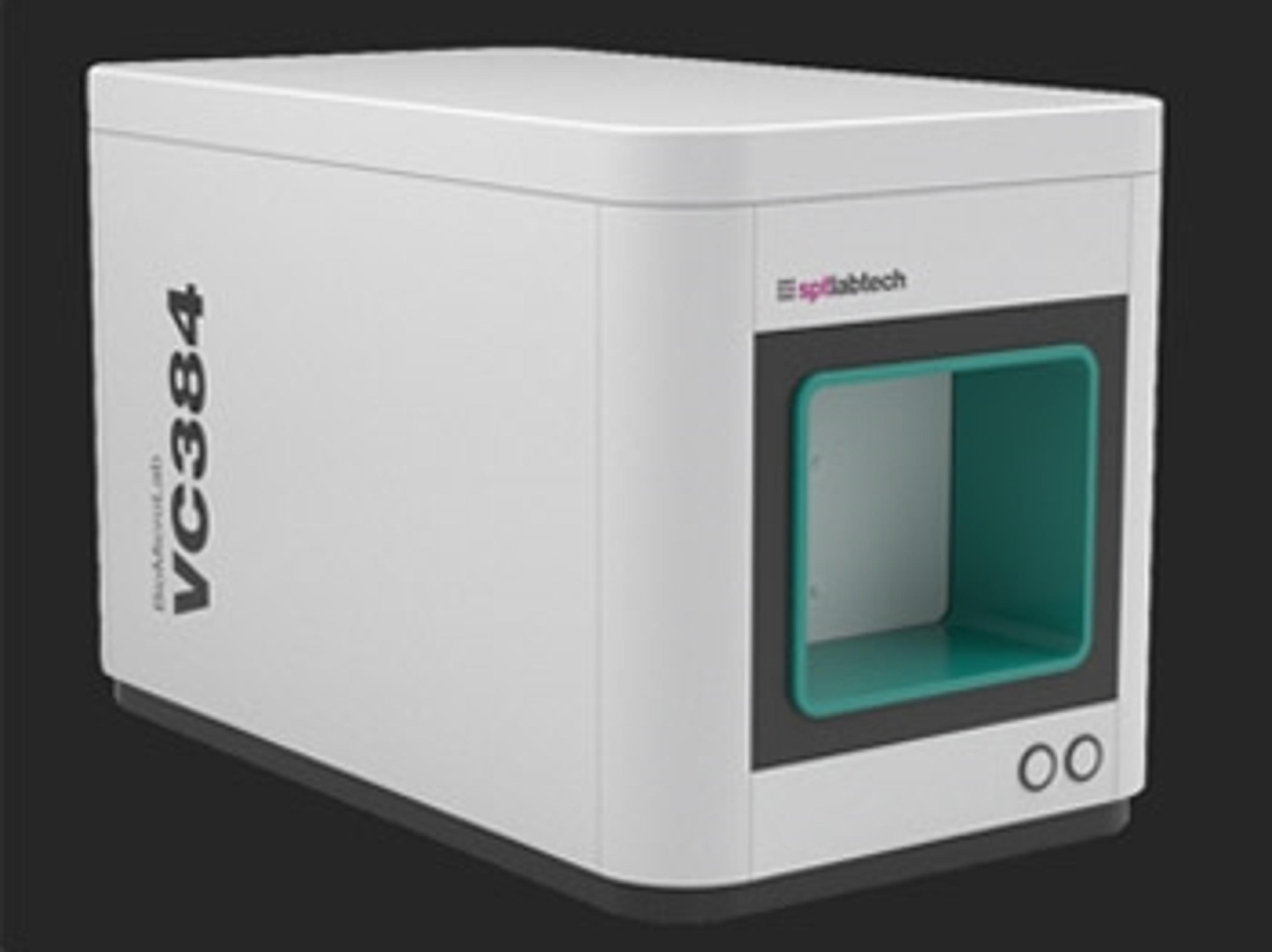

XL100: The BioMicroLab XL100 performs complex tube and vial handling tasks such as volume detection of low sample volumes, liquid transfer, labeling, capping, de-capping, re-arraying and more. Compatible with tubes and vials up to 125mm in height and designed with an interchangeable pick-head, laboratories can use the same instrument for different tubes and vials.

XL200: Similar in capabilities and function to the XL100, but with a larger deck capacity of 30 racks, the BioMicroLab XL200 also performs complex tube and vial handling tasks such as volume detection of very low sample volumes, liquid transfer, labeling, capping, de-capping, re-array and more. The XL200is compatible with the same variety of tubes and vials (up to 125mm in height) and is ideal for laboratories processing high volume runs or requiring deck spaces for reagents, wash areas or tip boxes.

Features: Re-array, reformat, or cherry-pick tubes Weigh tubes (tare & gross weights) Detect volume with the LevelCheck 2D Barcode decoding LIMS integration-ready Work list based operation Efficient for both small and large projects.