Tips for sustainably optimizing your nanoparticle preparation workflows

Learn how nanoparticles are transforming drug delivery in healthcare, and how ultrafiltration technology is being used for analysis and optimization of nanoparticle workflows

31 Jan 2022

Over the last century, new research methodologies have transformed the field of medicine by identifying, and even designing, novel drug targets at an increasingly fast pace. In parallel, scientists have also been investigating new ways to transport and effectively deliver a drug to its target location within the body.1,2 Nanotechnology - and specifically the manufacturing of nanoparticles - has received a lot of attention as a means to improve traditional drug delivery systems.

“Nanoparticles comprise a broad array of organic and inorganic molecules,” explains John Cashman, Global Product Manager for Sartorius Lab Ultrafiltration Solutions. “They can be characterized by their material, such as lipids, metals, or polymers, and by the final form in which they are used, such as vesicles or particles.”

“These particles have many potential applications within diagnostics, therapeutics and disease treatment, including imaging and targeted drug delivery,” Cashman adds. “In fact, nanoparticles form the key drug delivery component in the first ever mRNA vaccines to receive regulatory approval,” he explains, referring to some of the vaccines which are currently being used to tackle the SARS-CoV-2 pandemic. “These vaccines utilize lipid nanoparticles to transfect mRNA into the recipient’s immune cells, helping build immunity against COVID-19.”

In this SelectScience® article, we outline nanoparticle analysis and preparation workflows, explore how to achieve more sustainable production via ultrafiltration, and highlight top tips to optimize these processes.

Nanoparticle preparation workflow and analysis in drug delivery

Nanoparticles are typically produced in three steps: assembly, purification, and concentration. These steps can vary in stringency based on the application involved. For example, drug delivery applications require nanoparticles of high purity and efficiency to ensure that treatments are effective and do not cause undesirable side-effects. Drugs can either be conjugated to the nanoparticle surface or encapsulated within a vesicle assembled from lipids, a process referred to as the ‘functionalization’ of the nanoparticle. Functionalization is rarely 100% efficient and, to ensure that it has occurred successfully, various analytical and confirmatory analyses need to be performed.

An important analysis that is routinely conducted, to determine the quantity of material to be administered to patients and to ensure correct dosing, is that of measuring the nanoparticle’s conjugation or encapsulation efficiency. For this, a separation process - such as ultrafiltration - is necessary to isolate free- from nanoparticle-bound drug, thus enabling the amount of drug that has associated with the nanoparticle to be determined. Ultrafiltration utilizes membranes with ultra-fine pore sizes to separate molecules primarily on the basis of size. “There is usually a significant difference in size between the free drug and the nanoparticle-bound drug, which makes ultrafiltration an efficient technique to perform this separation,” elaborates Cashman. “By using a device where the functionalized nanoparticles are sufficiently larger than the nominal membrane pore size, the nanoparticle-bound drug will be rejected, while the much smaller, free drug molecules will pass through the membrane.” Thus, ultrafiltration helps separate out the free drug (in the permeate sample) from the functionalized nanoparticles (in the retentate sample). By comparing the drug concentration in the permeate versus the concentration of drug added at the start of the sample preparation, a measure of conjugation or encapsulation efficiency in percentage terms is obtained.

Sustainable production of nanoparticles: A case-study with graphene

Ultrafiltration can also be an indispensable method throughout the production process of nanoparticles. This is especially the case for difficult-to-produce nanoparticles like graphene, a commonly used substance in medical applications. While the initial synthesis is straightforward, the resulting graphene is highly acidic and contains several impurities. “It is the acidic conditions in the target location within the body - such as in tumor microenvironments - that trigger the release of the drug from the graphene surface,” shares Cashman. “This means that the pH of graphene is crucial to enable targeted treatment and it is therefore essential that graphene is extensively washed and neutralized after manufacture.”

This washing process is conventionally achieved through multiple centrifugation steps, taking up to one week to prepare relatively small quantities, with considerable manual involvement. Apart from it being limiting in terms of sample capacity and scalability, centrifugation also generates high quantities of graphene-containing waste, which can be harmful to the environment if not disposed of appropriately. Moreover, centrifugation might also lead to critical loss of yield in the supernatant fractions, which often contain the smaller graphene sheets due to their slower rate of sedimentation relative to the larger sheets in the sample. This is a significant drawback with centrifugation, as the size of these smaller graphene sheets makes them more biomedically relevant than the larger ones.

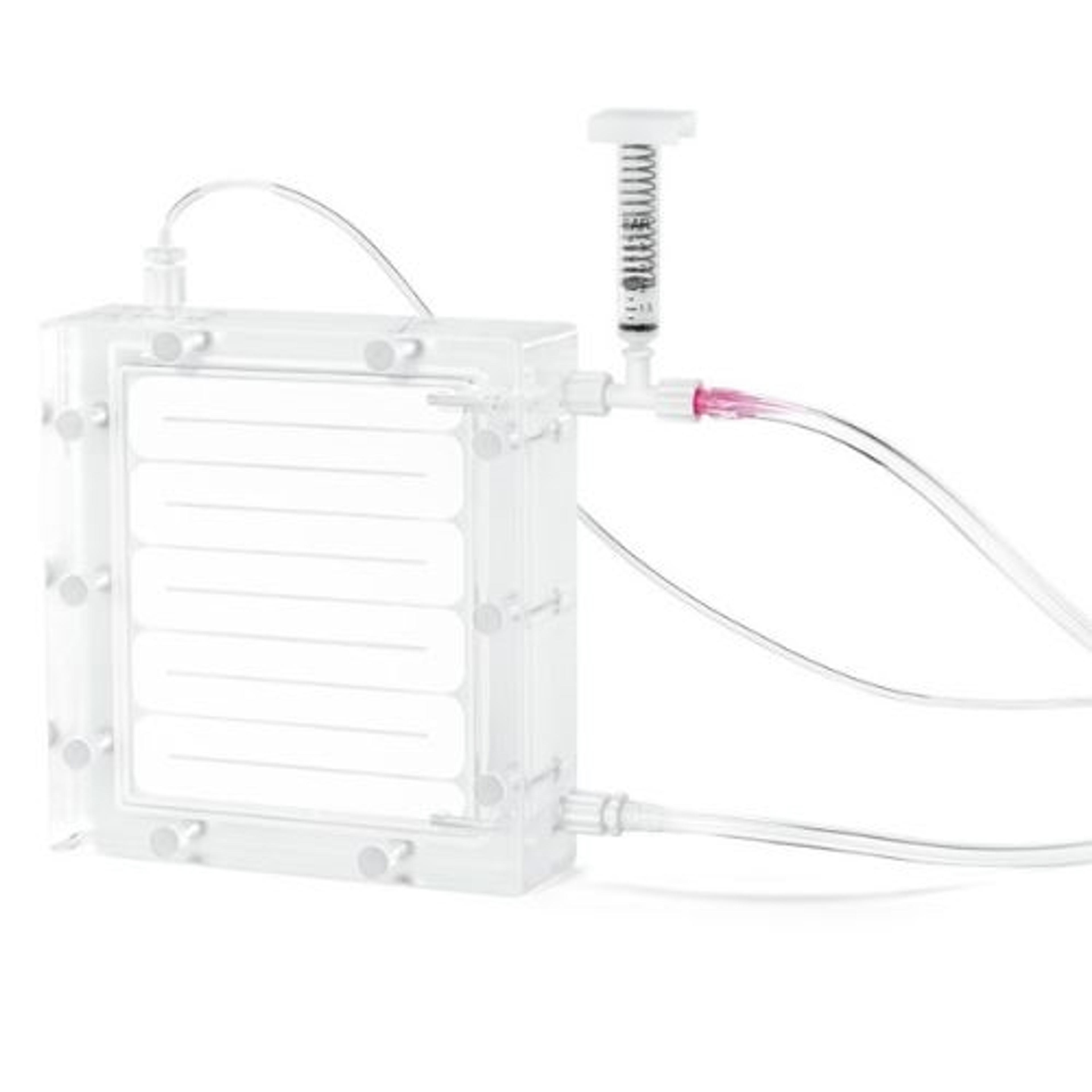

In the search for an improved and sustainable alternative to centrifugation, Sartorius teamed up with Abdelnour Alhourani, from the bioengineering group at the Norwegian University of Stavanger, to develop a tangential flow filtration (TFF) method for washing and pH neutralization of graphene. TFF allows continuous washing of nanoparticles by diafiltration. “The TFF method enables 95% time-savings, reducing hands-on time and graphene waste compared to centrifugation, while maintaining high graphene recoveries,” says Cashman. “We performed TFF using Vivaflow®, a crossflow filtration system capable of handling initial sample volumes up to five liters, which is suited to research and process development laboratories.” Unlike centrifugation, the ultrafiltration membranes in these devices effectively retain all sizes of graphene particles. This not only helps in preventing yield loss, but it also potentially lowers the quantity of starting material in commercial manufacturing. In addition, the TFF method can be conducted using process scale systems for manufacturing at volumes from hundreds to thousands of litres. This makes it an effectively scalable technique, overcoming the capacity constraints with centrifugation.

Find out more about the TFF method in this free resource >>

Tips to optimize the nanoparticle preparation workflow

“Key to ensuring high process speeds and recoveries is choosing the right membrane material and molecular weight cut-off (MWCO) for any target molecule,” mentions Cashman. “Ideally, multiple materials and MWCOs should be tested for each nanoparticle.”

As with the case of graphene, there are many examples wherein using ultrafilters instead of conventional techniques results in faster processing speeds, while maintaining or even increasing yields. It can be especially beneficial in cases where nanoparticles are used in the form of exosomes and other vesicles, which often require a concentration step during production. The typical approach for concentrating this type of nanoparticle - ultracentrifugation - is time-intensive and has limited capacity to handle large sample volumes. Moreover, the pressures exerted on the sample at high centrifugal forces also increases the risk of damage to exosomes, which subsequently reduces yields. In contrast, ultrafiltration is a faster, scalable, and gentler technique.

“For the best results when conjugation or encapsulation efficiency needs to be determined after nanoparticle functionalization, choosing devices with unsupported membranes such as cellulose triacetate may be preferred, as this can minimize the chance of free drug adsorption or trapping within the membrane matrix,” shares Cashman. “In applications where nanoparticles are labelled with agents, such as in diagnostic imaging, it becomes important to remove unbound dyes or isotopes. Taking a similar approach to that used prior to measuring conjugation or encapsulation efficiency, ultrafiltration membranes can be used to efficiently remove unbound dyes from nanoparticles.” In addition, diafiltration can be used together with ultrafiltration to increase the efficiency of the unbound dye removal.

Download the free Sartorius Ultrafiltration Products Application Guide for detailed device and MWCO recommendations for several nanoparticle types.

The versatile future of nanoparticles

It is clear that the potential of nanoparticles is just being realized. Beyond medical research, nanoparticles also bear relevance in the manufacturing of cosmetics and in coatings for self-cleaning surfaces. “The many applications of nanoparticles are constantly evolving and we expect that ultrafiltration will continue to play an important role in the purification and analytical sample preparation for these materials,” concludes Cashman.

References:

Mitchell M.J, Billingsley MM, Haley RM et al. 2021. Engineering precision nanoparticles for drug delivery. Nat Rev Drug Discov,20(2), 101–124. https://doi.org/10.1038/s41573-020-0090-8

Rizvi SAA, Saleh AM. 2018. Applications of nanoparticle systems in drug delivery technology. Saudi Pharm J., 26(1), 64-70. doi:10.1016/j.jsps.2017.10.012