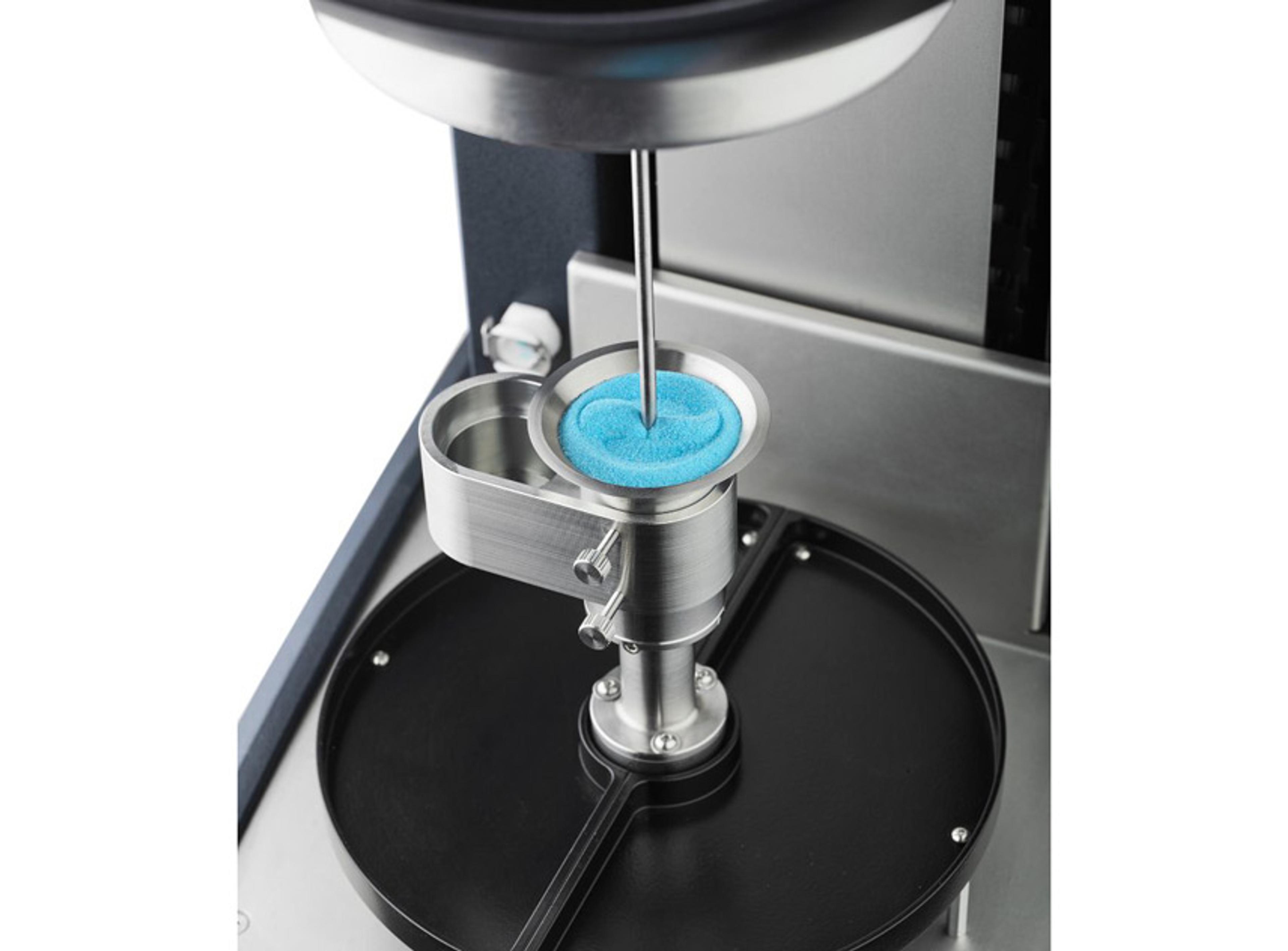

Mini-BeadBeater 24

The Mini-Beadbeater-24 disrupts up to 24 microbial or tissue samples with better than 95 percent efficiency. Cells are disrupted quickly and safely in the sealed system. The apparatus is easy to clean, has a small footprint and is essentially maintenance free. Compared to the Minibeadbeater-16, the Mini-24 adds advanced electronics for enhanced motor function, variable speeds of 2400-3800 rpm and a 30% increase in microvial c…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Great product.

Community sequence variation

I have used other bead beaters from this same manufacturer, this newer one seems a lot quieter. It is very efficient at homogenizing plant tissue.

Review Date: 20 Oct 2020 | BioSpec Products Inc.

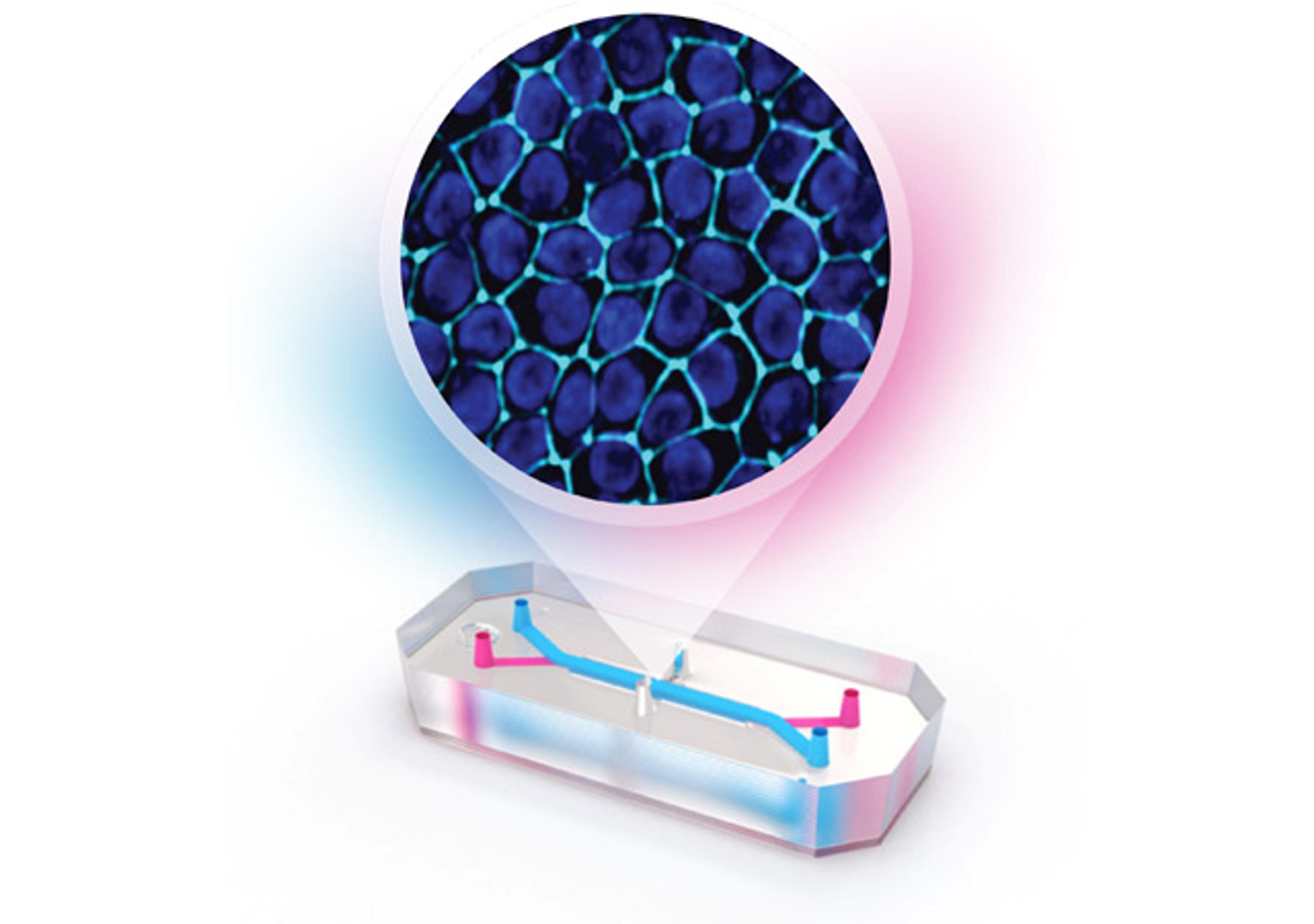

The Mini-BeadBeater-24 disrupts microbial cells and plant and animal tissue by violently agitating four to twentyfour 2 ml screw-cap microvials containing small glass, ceramic or steel beads and 0.1 to 1 ml disruption buffer. The performance of the Mini-BeadBeater equals or exceeds that of any other type or brand of cell disrupter. Even resistant samples like yeast, spores or fibrous tissue are completely homogenized in 1-3 minutes. The non-foaming, aerosol-free method preserves enzymes and organelles. In the presence of nucleic acid extraction media such as phenol, Gu-SCN or a commercial kit solution, DNA or RNA is recovered in the highest possible yield. The method is ideal for PAGE, PCR applications, and diagnostics using antibody or oligonucleotide probes. Because the beads and vials are disposable, there is absolutely zero cross-contamination between samples - essential for PCR techniques.

Protocols developed using a different model of the Mini-BeadBeater are transferable with minimal modification.

The Mini-Beadbeater-24 can also be used for dry grinding. Here, steel beads are added to hard samples such as hair, bone, teeth, seeds and minerals and are powdered in 10-60 seconds of operation. Resistant materials such as tendon, cartilage, rubber or some plastics can be powdered by pre-freezing the sample to liquid nitrogen temperatures (cryo-grinding), then grinding in the hard frozen state. Dry-grinding requires using special microvials resistant to breakage. When dry grinding with ceramic or steel beads at room temperature our 'XXTuff' microvials are recommended. Our Stainless steel microvials are available for dry grinding with steel beads at cryo-temperatures.