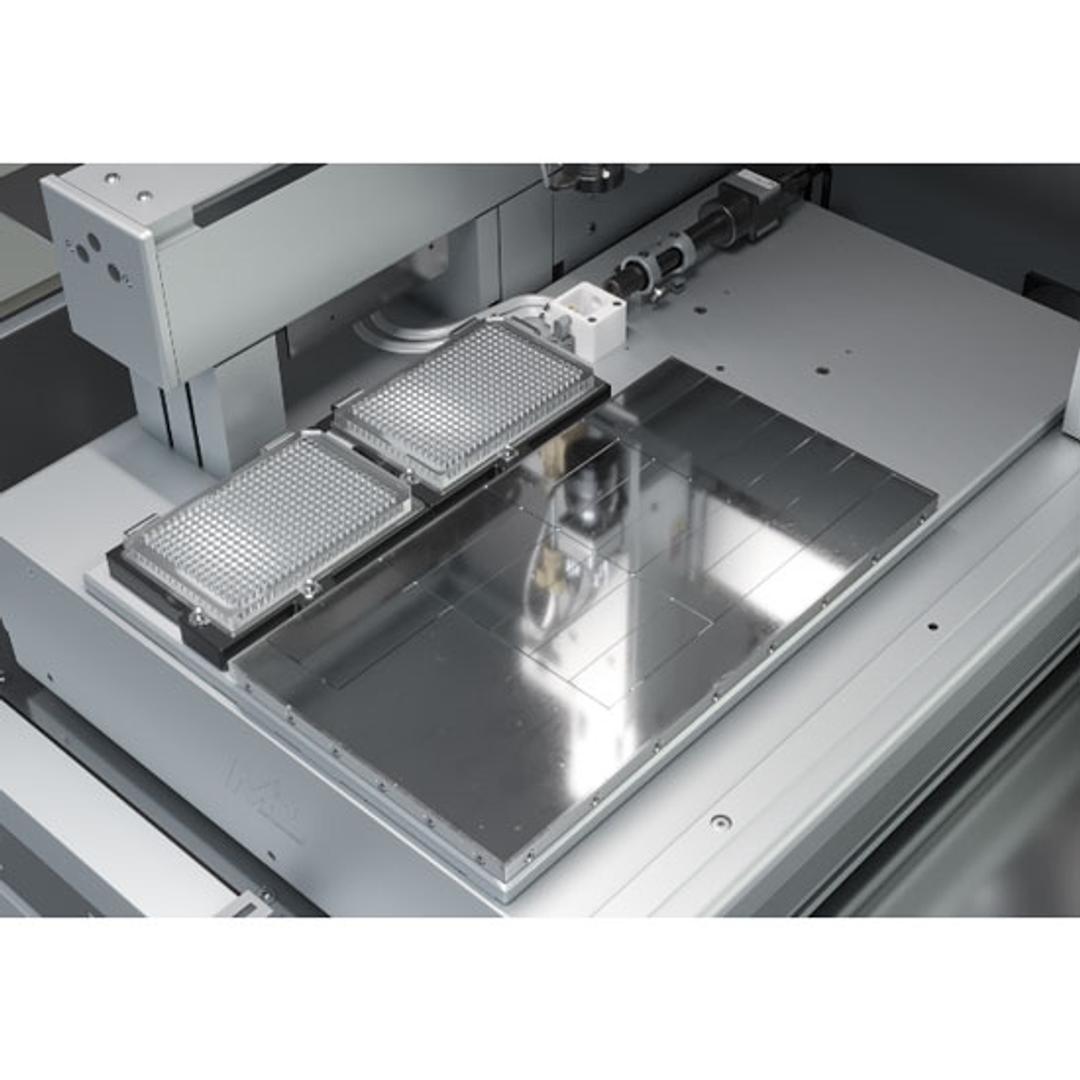

iTWO-300P Microdispensing Instrument

From picolitre to microlitre, contact and non-contact dispensing technology combined in one instrument. The iTWO is M2-Automation's entry-level system for R&D and small production, without cutting back on performance and flexibility.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Excellent machine! We can surely recommend it.

Living cell printing and cellular microarrays in microfluidic chips

We were one of the first buyers in 2013. We bought the iTWO-300 robot to dispense living cells, such as yeast cells and bone cells as living cellular microarrays in microfluidic chips. Our dispenser still performs as well as on the first day using both the solenoid (nanoliter droplets) and the piezo (picoliter droplets) dispenser. The customer support is excellent: quick, efficient, friendly, and always eager to provide useful information for troubleshooting. For our research, we made a good choice of buying this equipment.

Review Date: 31 Aug 2022 | M2-Automation GmbH

Without the iTWO we would have been lost!

mass production of NAT standards

The robust and steady workflow enabled us to deliver uniform products. The technical support is exelent and solved our problems usually with in a day. The software could be a little more intuitive but works fine for us. We use the system at the upper limit in the µl scale and operate easily with a tolerance of 1-2%. Overall the iTWO was the best decision to scale up and standardise our production.

Review Date: 25 Jul 2022 | M2-Automation GmbH

The instrumentTWO-300P provides its users with a broad range of custom-tailored solutions. The iTWO-300P is ready for any challenge to come. With a large area for production and an improved repeated positioning, it is the ideal choice for research and development or small-scale production.

Of course, additional new options like the contact-based Pin-Dispenser, a vacuum table, humidity control and HEPA-filter are only a few of the many options that you can combine with our established technologies, like the Quattro-Dispensing or the online-QC, as well as a variety of camera options.

In its compact design, the iTWO series can house everything your process needs. Starting with a precision axis system, each iTWO can be modified with a variety of support systems for complete environment and process control.

Providing a volume range from picolitre to microlitre, it is suitable for a variety of applications. Our contact and non-contact dispensing technology is capable of handling limited volumes of even the most sensitive aliquots, including experimental orientated microarray printing or a high throughput production of diagnostic chips, membranes, glass slides, MTPs, wafers, microfluidic channels and planar films.

The iTWO-300P features:

- Hermetically sealed housing

- Built-in PC

- Built-in pressure and vacuum control

- Intuitive M2-Automation InDot software

- Optional high-duty mobility table

- Humidity control

- Online QC

- Source and target-temperature control

- Deionizer

Usual Applications:

- Lab-on-a-Chip / dipsticks

- Compound library screen

- DNA microarrays

- Biosensors

- Drug discovery / immunoassays

- Microfluidic chips and channels

- Lateral-flow applications