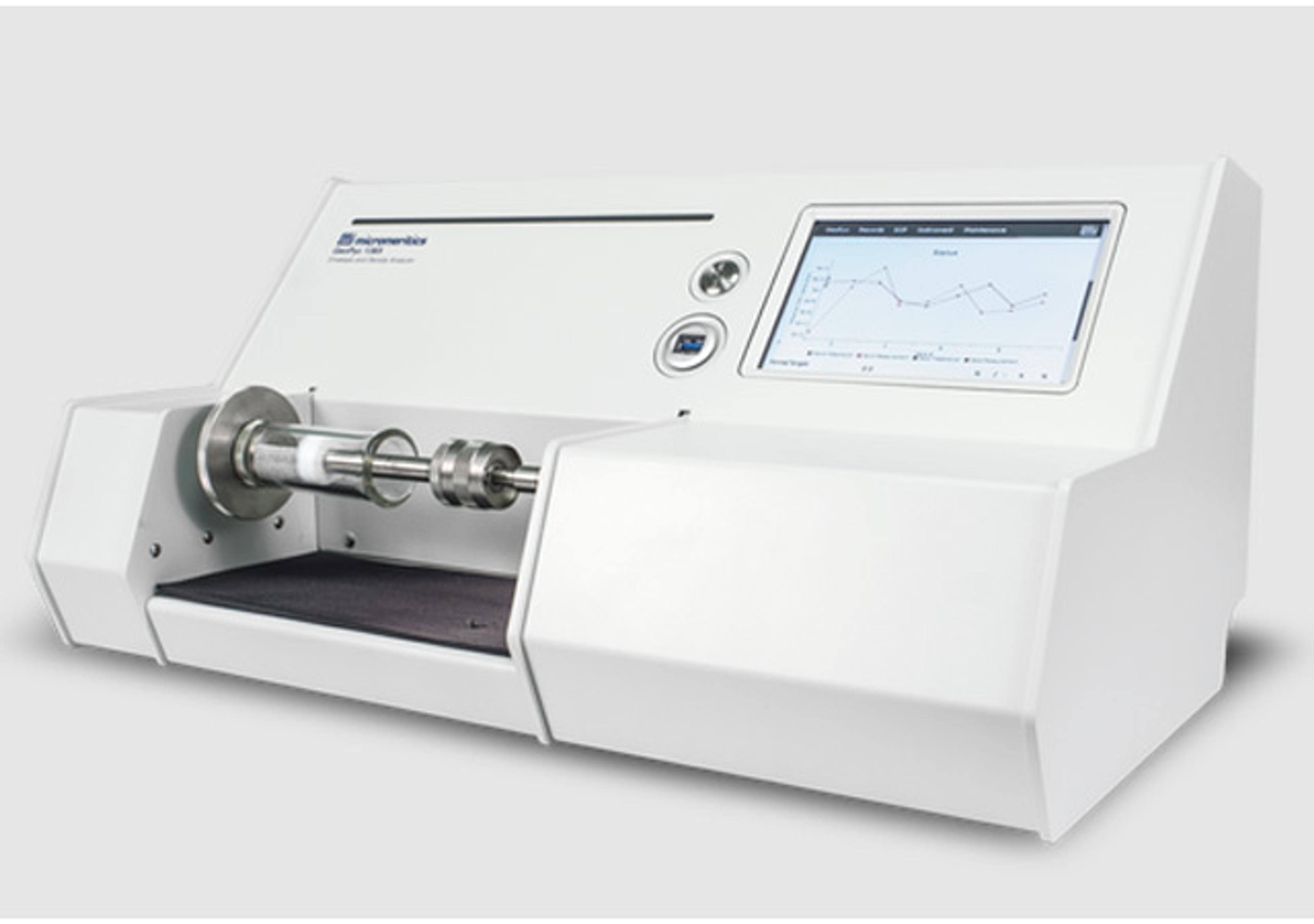

HELOS/KR-Vario

Particle size analysis for extended aerosols and sprays containing droplets or solid particles ranging from 0.5 µm to 3,500 µm in a flexible measurement setup

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Helos KR/Vario is a cost-effective, accurate, user-friendly particle size analyzer.

Agricultural Tank Mix Application

Helos KR/Vario is the last frontier of modular laser diffraction sensor for particle size analysis. The equipment has a robust configuration and easy setup, as well as easiness of operation. The PAQXOS software is very user friendly, with several possibilities of changes to adjust the parameters and configuration of tests and reports to adjust to the needs of the company. Definitively, the best cost-benefit particle size analysis of the market. And the most accurate one!

Review Date: 17 Jul 2025 | Sympatec GmbH

We raised the bar of of our service and reliability of the company to the customers!

Measurement of spray droplet size from agricultural sprays using laser difraction

The equipment added an extreme value to the company's service for our customers.We are able to determine and reduce spray drift potential and to optimize chemicals usage and spray parameters and nozzle choice through droplet size analysis. With fast and automatic measurements within a wide range of droplet size, the equipment generates repeatable and reliable results of critical parameters for the spray tank mix characterization and application optimization. Definitively, the best choice of the category.

Review Date: 17 Apr 2023 | Sympatec GmbH

The laser diffraction sensor HELOS-KR-Vario is designed for particle size analyses of extended sprays and aerosol clouds containing droplets or solid particles ranging from 0.5 µm to 3,500 µm. The open measuring zone, which can be varied in its width, supports the flexible adaptation of the optical measurement system to individual customer requirements in challenging technical applications in laboratories or pilot plants.

Aerosol generators or atomizer nozzles with their spray cone can be directly positioned in the measuring zone of the standard profile, which offers a working depth of up to 1,400 mm. With the separable housing components of the HELOS/KR-Vario, it is also possible to integrate special structures such as wind tunnels or spray chambers in a measurement setup. Here, the light source and detector are mounted on their own profiles, positioned and adjusted – if necessary even over larger distances. Optional purge air nozzles ensure low contamination of the optical components and thus support the high availability of the overall system.

For the investigation of dynamic changes in the particle size distribution of an aerosol cloud or of a spray cone, a time-resolved data acquisition (pulsed measurement) is recommended. With a frequency of up to 2,000 measurements per second and a measuring duration of up to 1,000 seconds, the dynamic behaviour in continuous spray processes can also be tracked. If, by contrast, an averaged droplet size distribution over a longer period of time is of interest, then it is possible to start an individual measurement that integrates the measurement data over the defined period of time.

With time-segmented measurements, a subsequent investigation, selection and summary of time segments within a measurement are possible. This allows both temporal changes in droplet size distribution during the measurement to be investigated as well as location-dependent distributions of droplets recorded at different positions of the spray cone during a measurement. Multiple separate measurements are not required. Reports and diagrams document and visualise not only the droplet size distribution but also the temporal course of all data of the measurement as well as the segment selection on which the result is based.