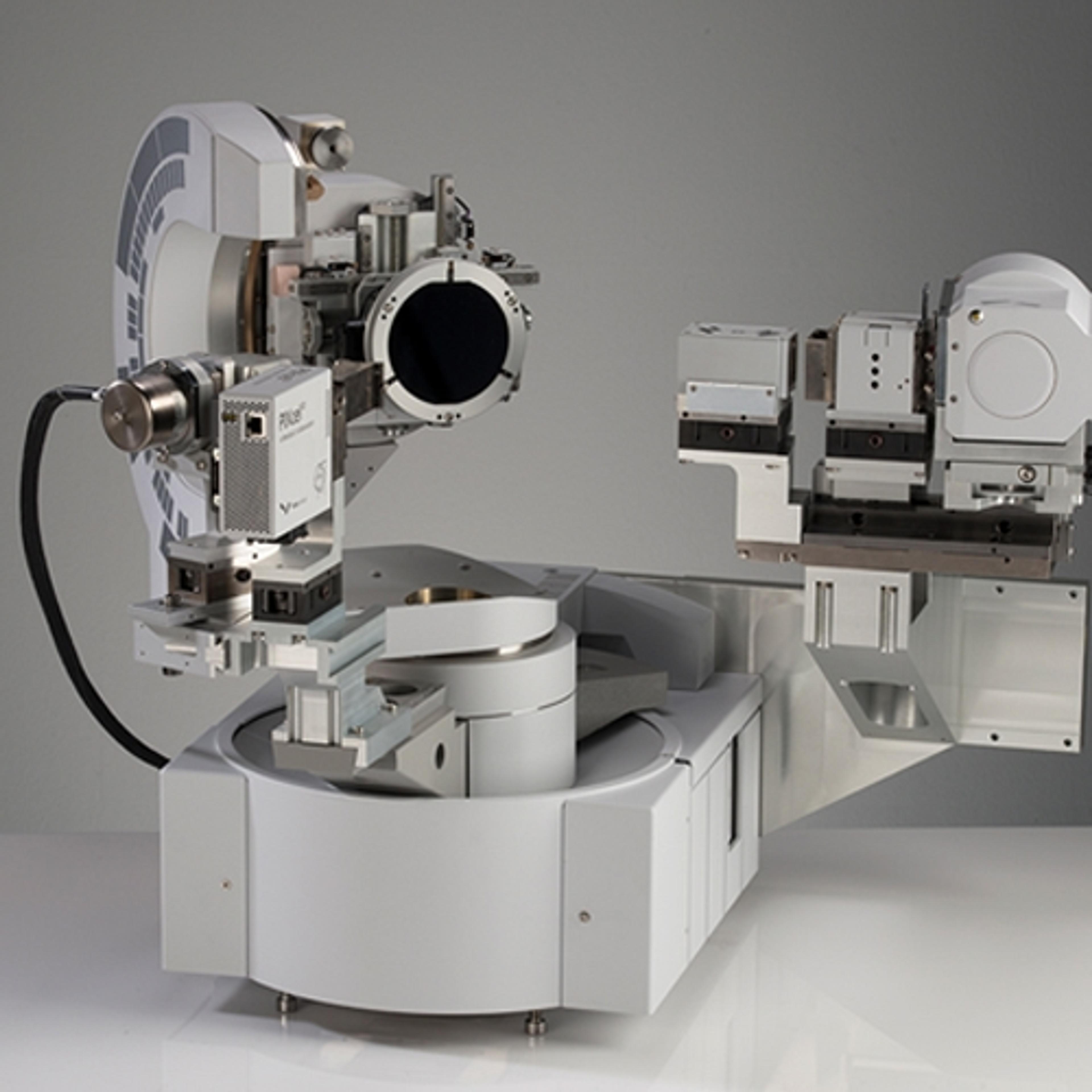

CNA3 cross-belt analyzer

A rugged, simple and versatile solution to your process control needs

Has brought real-time results to our ore discrimination/classification process.

Analyze 2 grades of chemical ore for MgCO3 and SiO2 level discrimination

Once set up and properly calibrated for our application the correlation with laboratory analysis was spot on and any shift was easily detectable. Our unit was the first application in the lime industry so some of the learning curve for the Panalytical support team went hand-in-hand with ours. Now any deviation from the expected result is caught and corrected within a few minutes, instead of 30 - 90 min. The value has been returned many times over.

Review Date: 1 Nov 2019 | Malvern Panalytical

Manufacturer's Response

Thanks Kevin for the review. We are glad to hear that any deviation from the expected results is detected and corrected when needed with the support of this instrument.

CNA3 is one of the latest generation of the CNA family. It has been entirely redesigned to be suitable for tough environments such as underground mines, but still features the cutting-edge Sodern neutron technology with unmatched lifetime and neutron output stability (PFTNA).

CNA3 provides high-frequency online elemental analysis of the bulk material on the belt. No sampling is required as material is measured in real time on the conveyor belt.

This compact and rugged design is completely underneath the belt - variation of belt load and particle size common in the mining industry doesn’t affect the performance of the system. This is a key design feature to provide stability and representativeness for an efficient process control.