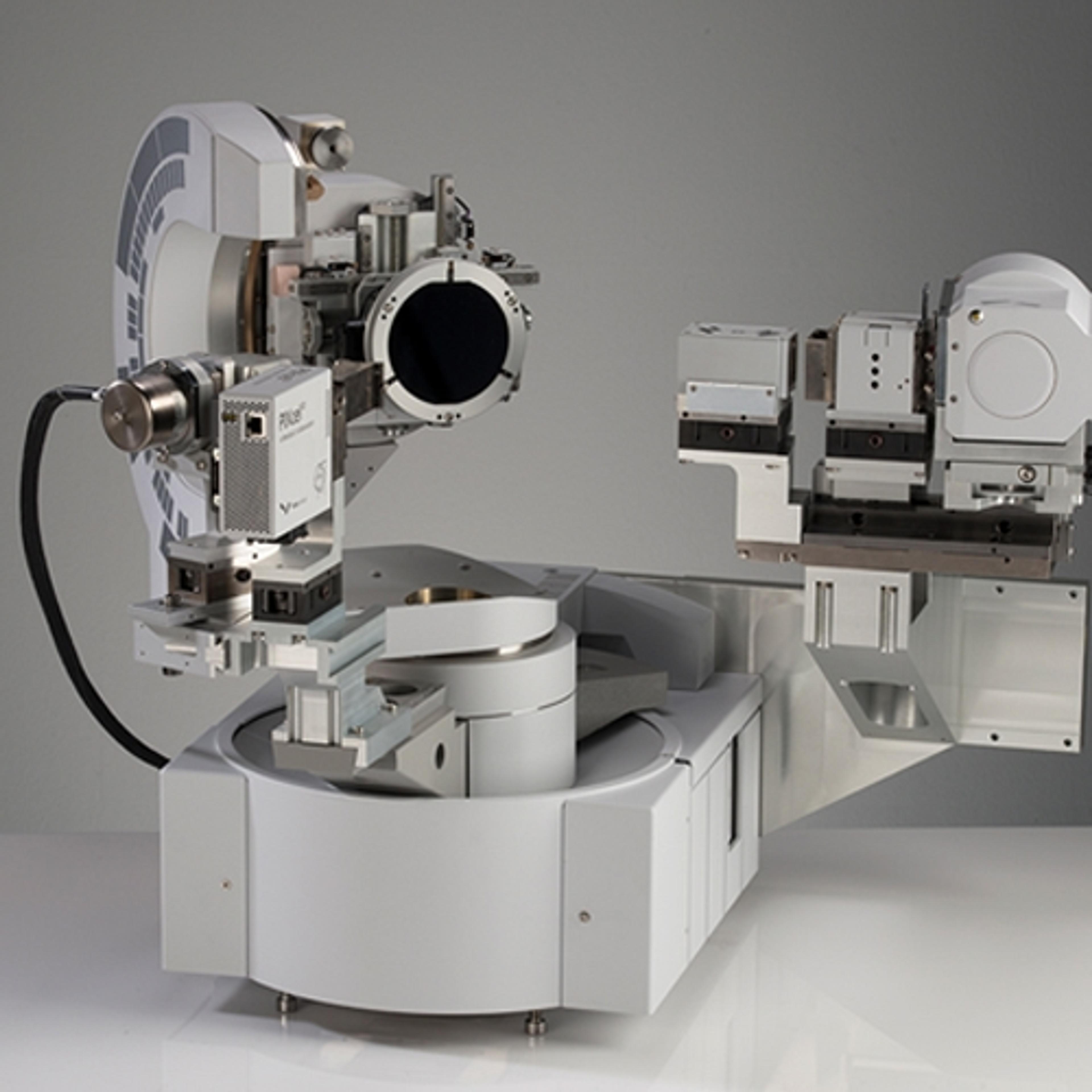

Claisse Eagon 2

Safe, simple, high performance. The Claisse Eagon 2 fusion instrument is fully automatic. It can process two samples simultaneously and is used to prepare glass disks for XRF analysis.

Great instrument.

Furnace for glass beads for XRF

Extremely easy to use and very reliable. Requires little maintenance on the user end.

Review Date: 15 Jan 2021 | Malvern Panalytical

Manufacturer's Response

Thank you for your comments about our Eagon 2. The Malvern Panalytical team is proud that you rely on our sample preparation equipment for quality control in your laboratory.

The Claisse Eagon 2 fusion instrument is fully automatic. It can process two samples simultaneously and is used to prepare glass disks for XRF analysis.

It processes:

- Mining and geological samples

- Bauxites, alumina

- Chromites, cobaltite, dolomite, ilmenite, rutile, molybdenite

- Rare earth elements

- Potash, phosphates, fertilizers

- Cements, lime, limestone, carbonates, clay

- Catalysts, zeolites

- Cosmetic, pharmaceutical and environmental samples

- Sulfides, fluorides

- Hematite, magnetite, iron ores

- Refractories, silica, silicates, glass, ceramics

- Coal, ashes

- Steel, ferroalloys, slags

- Pure metals, non-ferrous alloys, silicon carbides

- Polymers, pigments, synthetic rubbers

This instrument leads to high performance and productivity in the laboratory since its two fusion positions can work independently (synchronous or asynchronous mode) and because it guarantees reproducibility as well as optimized fusion conditions. Its molds and crucibles holders are made of superior quality ceramic to ensure the lowest contamination.

The interlocked doors eliminate the contact with hot materials and surfaces for an enhanced security and a total cold-to-cold operation.

The Claisse Eagon 2 instrument has a one-touch operation feature and a wide range of predefined fusion methods that make it really easy to operate in the laboratory.

It has distinguishing features that allow a quick return on investment (ROI) such as casting dish sensors that prevent damage related to pouring without the molds in place.

Other Benefits of Using the Claisse Eagon 2 Fusion Instrument

- Optional exhaust adapter that limits the infrastructural requirements

- Pause and inspection function to visualize the fusion process during the fusion cycle

- No O2, compressed air or water cooling system needed