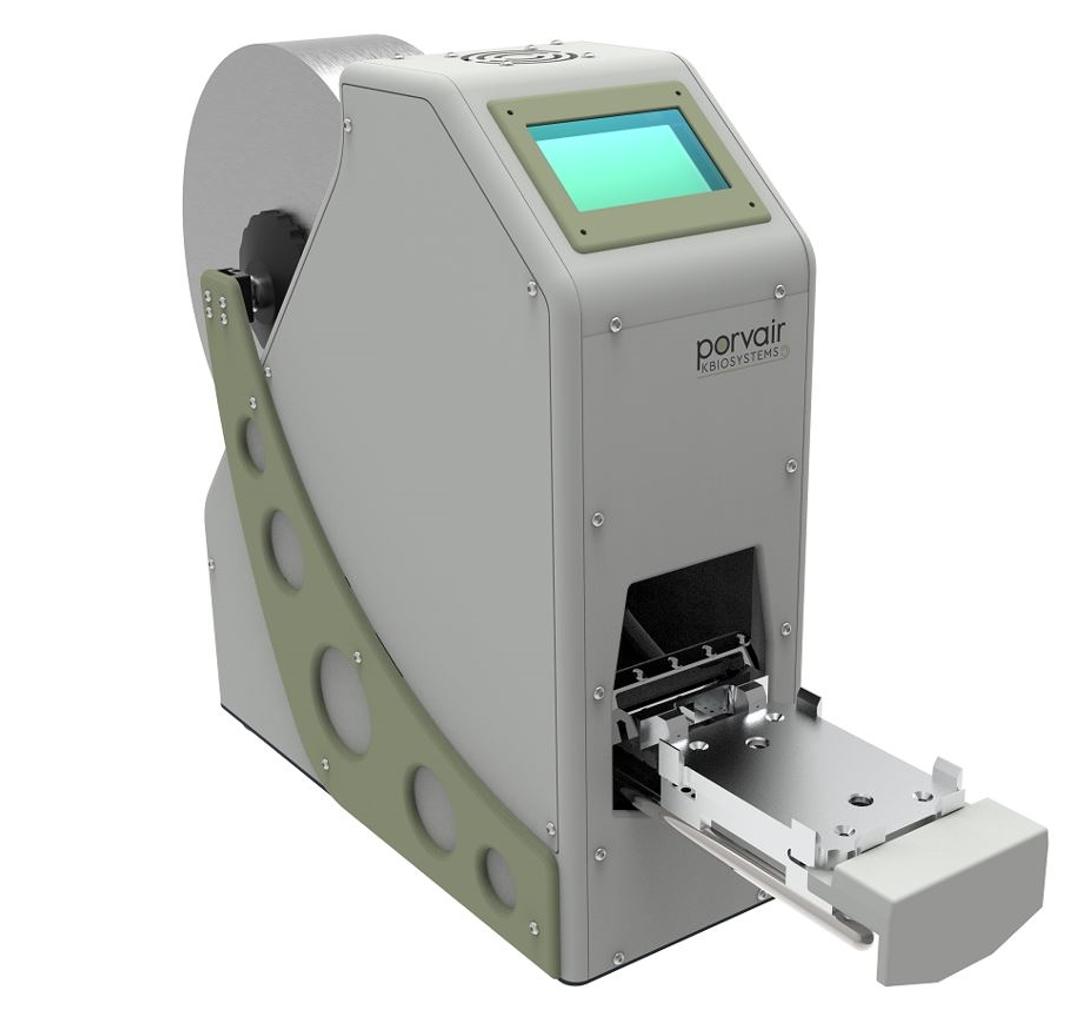

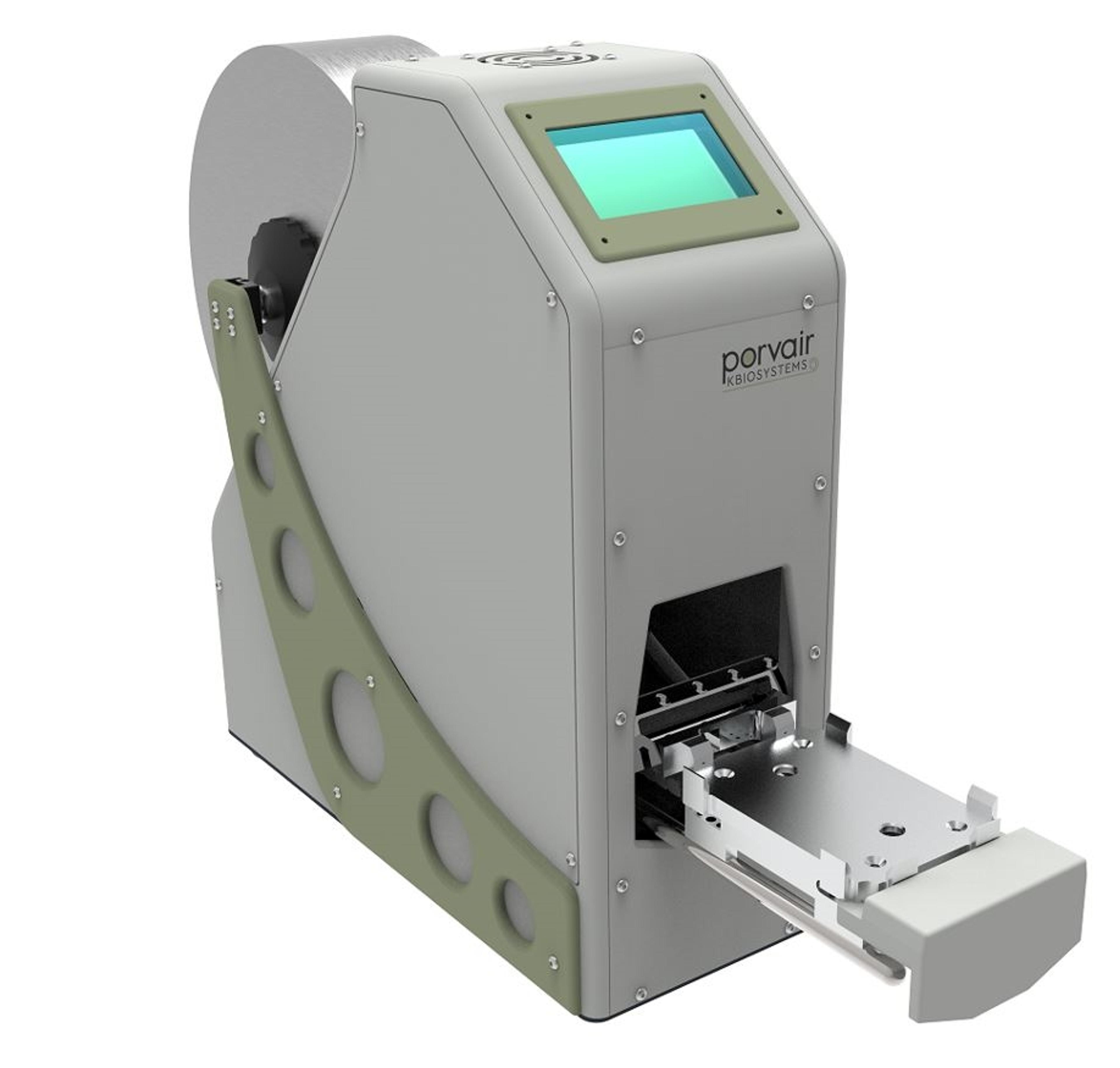

Chameleon XT automated heat-applied microplate and tube rack sealer

Automated heat-applied microplate and tube rack sealer

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

The Chameleon XT unit is an automated heat-applied microplate and tube rack sealer. The unit uses a roll of surface-modified aluminum or plastic film approx. 78mm wide and 600m long, the roll is positioned to the rear of the sealing section via a removable stand, using a total inline method the film is pulled through the main unit, cut to between 125mm and 130mm in length, and then applied to the plate top surface to create the seal between plate and film. Offering complete versatility, the sealer Series will work with a wide range of plates, tube racks, and custom applications shallow and deep well formats, and custom moldings. Our latest range of seals supports polystyrene, polypropylene, and CoC & CoP plate formats with a range of film substrates please contact us for further details.

- Able to use multiple manufacturers' plates across applications

- Supports polystyrene, polypropylene, and CoC & CoP plate formats

- Easy to program

- Operator and integrator friendly