How immunoassay innovation has expanded the biotherapeutic development toolbox

Experts share how commitment to bioanalytical innovation and quality has enabled success in biotherapeutic development

11 Jan 2024

(left) Ann-Charlott Steffen, Principal Scientist, and (right) Robin Lundberg, Production Manager at Gyros Protein Technologies

Microfluidic-based immunoassays are crucial tools for analyzing antibody, protein, and gene therapy-based biotherapeutics during development.

In this exclusive interview, we speak to Ann-Charlott Steffen, Principal Scientist and Robin Lundberg, Production Manager at Gyros Protein Technologies, a leading bioanalytics solutions provider celebrating the 20th anniversary of its flagship product, the Gyrolab® Bioaffy™ Compact Disk (CD) circular microfluidic labware. Reflecting on their journey with the company, the experts shed light on the dynamic landscape of bioanalytics, elaborating on how the company’s offerings have advanced with time to meet evolving customer needs.

A legacy of bioanalytical support spanning two decades

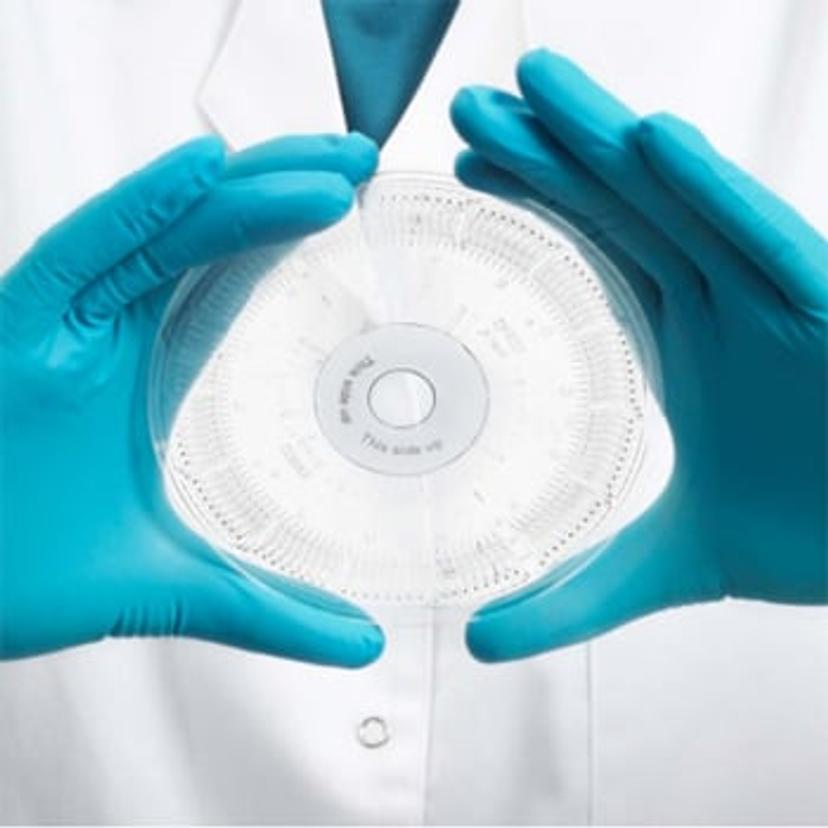

Back in 2007 when he joined the Swedish headquartered company, the Gyros Protein Technologies flagship product was still in an experimental phase, marvels Lundberg. Gyrolab® Bioaffy™ CDs, the microfluidic labware that Lundberg is speaking of, lies at the heart of the company’s Gyrolab automated immunoassay platform. Constructed of affinity columns using streptavidin-coated beads at nanoliter-scale, the CDs enable running of fully miniaturized enzyme-linked immunosorbent assays (ELISA) over a broad range of concentrations.

Recalling how the innovative thinking behind the Gyrolab Bioaffy CD design came about, Lundberg says, “As a company, we had just shifted our focus from MALDI technology to immunoassays back then. We worked closely with our R&D specialists to engineer highly reproducible microfluidic structures to enable high binding capacity in the flow-through columns, while minimizing contact times between the interactants to reduce matrix interference. Today, the consistency and performance demonstrated by our CDs make them a reliable choice for our customers who look for reproducible bioanalytical data that meets regulatory standards.”

Steffen, who has been with Gyros Protein Technologies for over a decade now, shares that she joined Gyros after six years of being a loyal customer, having used the Gyrolab assays at three different client sites. Elaborating on her unique dual perspective as both a customer and an insider, she says, “In my previous experience, I worked extensively with Gyrolab pharmacokinetic (PK) assays and anti-drug antibody (ADA) measurements, as well as some pharmacodynamic (PD) assays. As a customer, I always appreciated the fact that these assays were outsourced to us promptly. Once the company’s in-house team established the assay, the semi-automatic nature of the assay reduced the bulk of the manual steps we had to undertake, making optimization straightforward. Now, as part of the Gyros Protein Technologies team, I recognize the value of offering our clients this ability to optimize kit development and achieve a solid assay when using Gyrolab solutions.”

Versatile immunoassay types and diverse applications allow users to adapt to evolving bioanalytical demands

Our goal is to offer a range of diverse Gyrolab CD types enabling researchers to streamline their processes, increase the sensitivity of their assays, and exert a tight control over the workflow.

Ann-Charlott Steffen

Gyros Protein Technologies

Delving into the wide range of applications that Gyrolab support today, Steffen explains that while the initial focus had been on providing PK assays, Gyros Protein Technologies has since expanded its offerings, “Our goal is to offer a range of diverse Gyrolab CD types enabling researchers to streamline their processes, increase the sensitivity of their assays, and exert a tight control over the workflow. Thus, apart from improving our production processes, we have tested several microstructures and expanded CD volume capacities making them up to 20 times more sensitive.” The range of Gyrolab Bioaffy CDs available today differ primarily in the sample volumes they process, and thus in the assay sensitivity they offer. The Gyrolab Bioaffy 1000 and 4000 offer higher sensitivity compared to the Gyrolab Bioaffy 200 which processes 200 nL of sample volume. The HC CDs on the other hand – the Bioaffy 20 HC, 1000 HC, and 4000 HC CDs – provide a higher binding capacity, which improves performance with reagents of low affinity compared to the non-HC CDs.

Lundberg highlights that the demands from bioanalysts and bioprocess scientists have evolved significantly over the past two decades. Customers now seek simplicity, reliability, and consistency in their assays, and Gyros Protein Technologies has adapted its offerings in response to these demands. In agreement, Steffen concurs that customers have shifted away from experimental methods, instead seeking off-the-shelf solutions and ready-to-use kits.

Discussing the evolution of Gyrolab products over the years, Steffen tells us that the team has made an active effort to keep their ears to the ground and continue innovating CD designs to meet customers’ needs. “For example, we identified that customers were experiencing challenges in obtaining consistent ADA measurements, and could benefit from automation in this process,” she shares. “In response to this, we designed the Gyrolab Mixing CD 96 that integrates a sample preparation step for example inclusion of an acid dissociation step when analyzing anti-drug antibody measurements. By integrating sample preparation, we enabled clients to reduce the assay complexity as well as the risk of error from additional manual steps, while also shortening turnaround time. In recent years, our CDs have improved significantly in detecting and measuring host cell protein (HCP) residues in drugs post-production as well.”

Faced with an increasing demand for its CDs and other products over the last two decades, Gyros Protein Technologies has successfully implemented automation alongside additional workforce training and expansion to keep up with the increasing production demand. Mirroring the customer trajectory over time, the company has transitioned from offering experimental, manually driven processes to providing ready-to-use, expert-designed kits that can be run without the need for assay optimization.

Gyrolab Bioaffy CDs offer solutions for a broad range of immunoassay applications. Running immunoassays at nanoliter-scale vastly reduces sample requirements and reagent consumption

Today, many customers lack the expertise or resources to develop in-house assays, which makes ready-to-use offerings from Gyros Protein Technologies as well as expertise provided by Field Application Scientists invaluable to them, Steffen adds. “Additionally, our Custom Assay Services further supports customers by providing extensive assistance in biomarker labeling and assay development, including aiding in selecting the best suited reagents.”

A future of innovative immunoassay solutions, with a focus on reliability

From the beginning, one constant factor – regardless of the product application – has been the Gyrolab team's unwavering dedication to quality and traceability. This focus has been a key driver of the company's success, asserts Lundberg. “We have always excelled in maintaining our documents system and optimizing our standard operating procedures. Robust quality controls (QC) are intrinsic to our production process, beginning with rigorous testing of all incoming raw materials used in our CDs for both quality and consistency,” he notes. “This is followed by inline QC steps at multiple stages to ensure the highest quality standards are maintained, focusing on ensuring accurate and precise responses in our assays.” Additionally, each Gyrolab Bioaffy CD undergoes final QC testing, guaranteeing batch-to-batch product consistency and reliability.

As Lundberg confirms the company’s commitment to growing the team and continually improving its processes, Steffen hints that Gyros Protein Technologies will continue to launch new kits, CDs, instruments, software, and electronic components to meet the ever-evolving needs in bioanalysis. With the promise of continued innovation, an exciting future lies ahead for bioanalysis solutions, Steffen concludes.