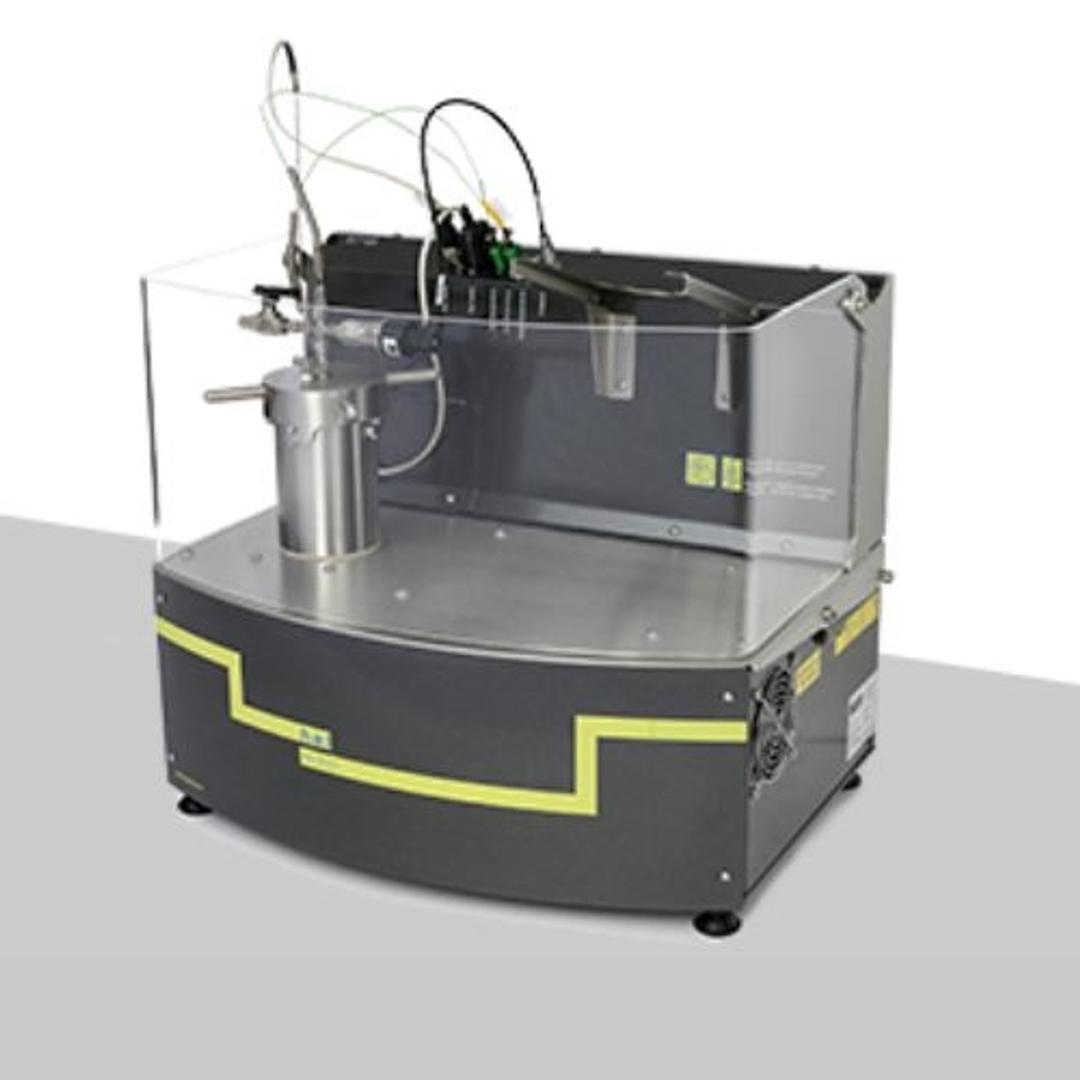

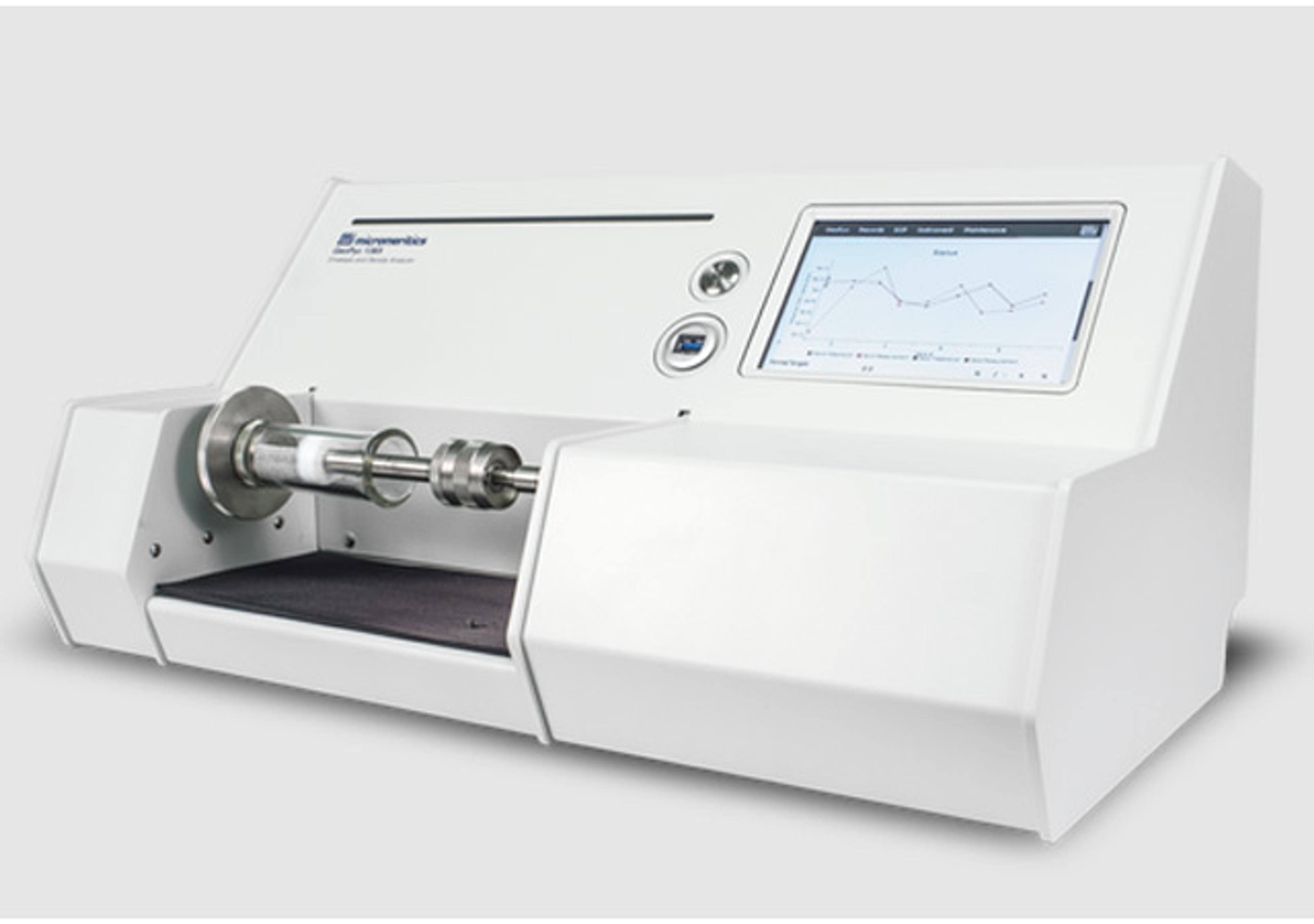

Phi-TEC I

The Phi-TEC I is an adiabatic calorimeter that enables the characterization of thermal runaway hazards during process development and scale-up. The Phi-TEC I replicates industrial (large volume) conditions on a lab-scale, enabling thermal runaway hazards to be characterized safely and efficiently.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Via direct sample temperature measurement and by rapidly responding to any thermal changes, the Phi-TEC I accurately tracks exothermic events and maintains adiabatic conditions. This adiabatic screening enables thermal events to be defined with the accurate characterization of the onset temperature (Td) and facilitates the calculation of other key parameters, such as the rate of pressure change, the adiabatic temperature rise (∆Tad, d), and the time to maximum rate (TMRd).

Applications

Rapid reactions

If there is a need to characterize especially rapid decompositions, the Phi-TEC I offers a high data-rate acquisition option, which provides higher resolution data on the rate of pressure and temperature changes. When scaling up a process, accurate knowledge of an exothermic event is vital to ensure the magnitude of the thermal runaway risk is fully understood.

Adiabatic calorimetry

Large scale reactors lose very little of the heat generated in a reaction to the surroundings. This poses a potential hazard when operating at large scale, as that heat will be retained within the reactor. At best this will require plant cooling and at worst may trigger a thermal runaway.

The Phi-TEC I mimics the processes at large scale, while operating at laboratory volumes.

Characterizing the thermal runaway (4)

Secondary thermal runaway risk

Providing a direct measurement of the sample temperature, coupled with a rapid response to thermal changes, the Phi-TEC I accurately tracks exothermic events and maintains adiabatic conditions.

Adiabatic screening of a process enables accurate characterization of the onset temperature (Td) and facilitates calculation of the time to maximum rate (TMRd), the adiabatic temperature rise (ΔTad,d) and the rate of pressure change. These key parameters can help describe the magnitude of the thermal runaway hazard.