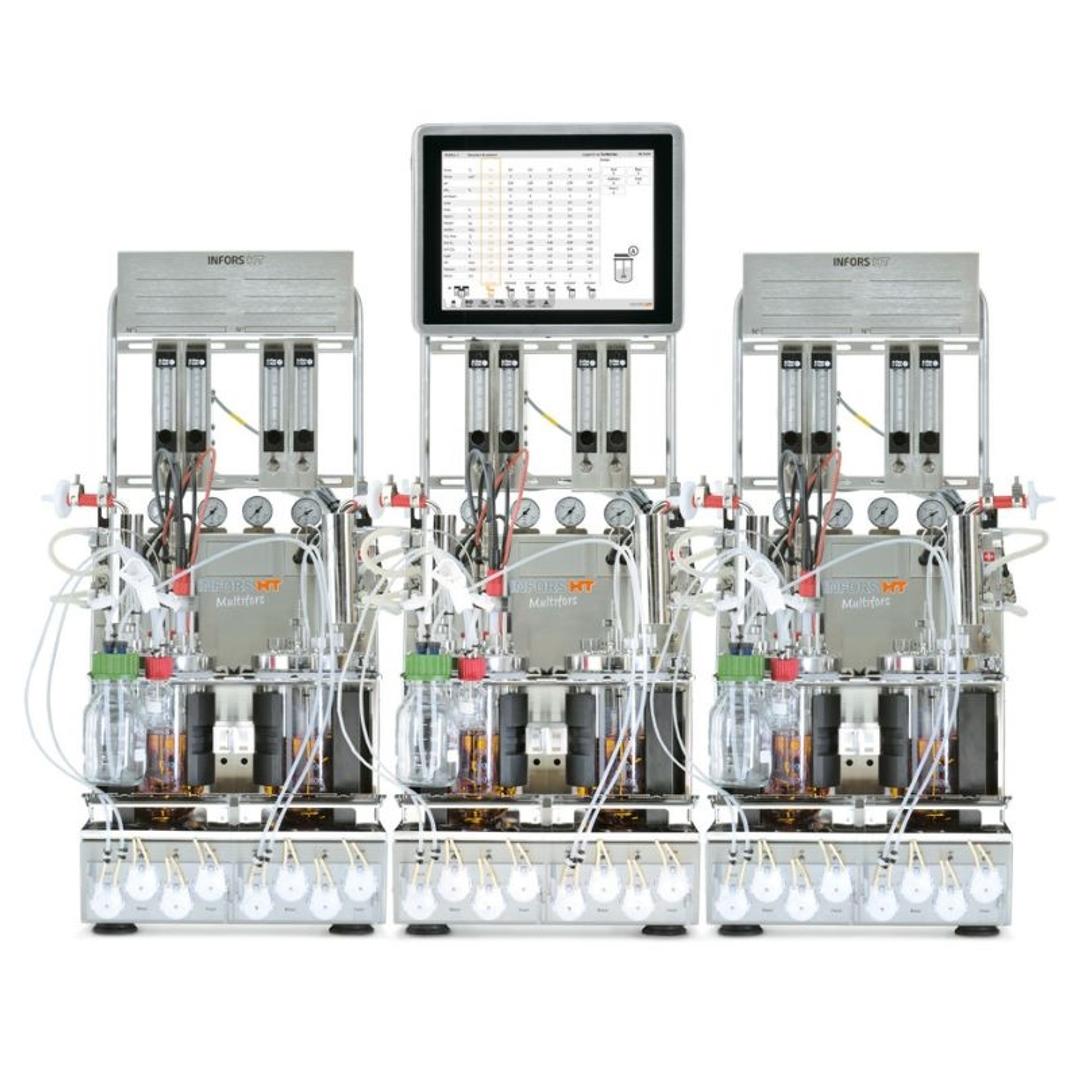

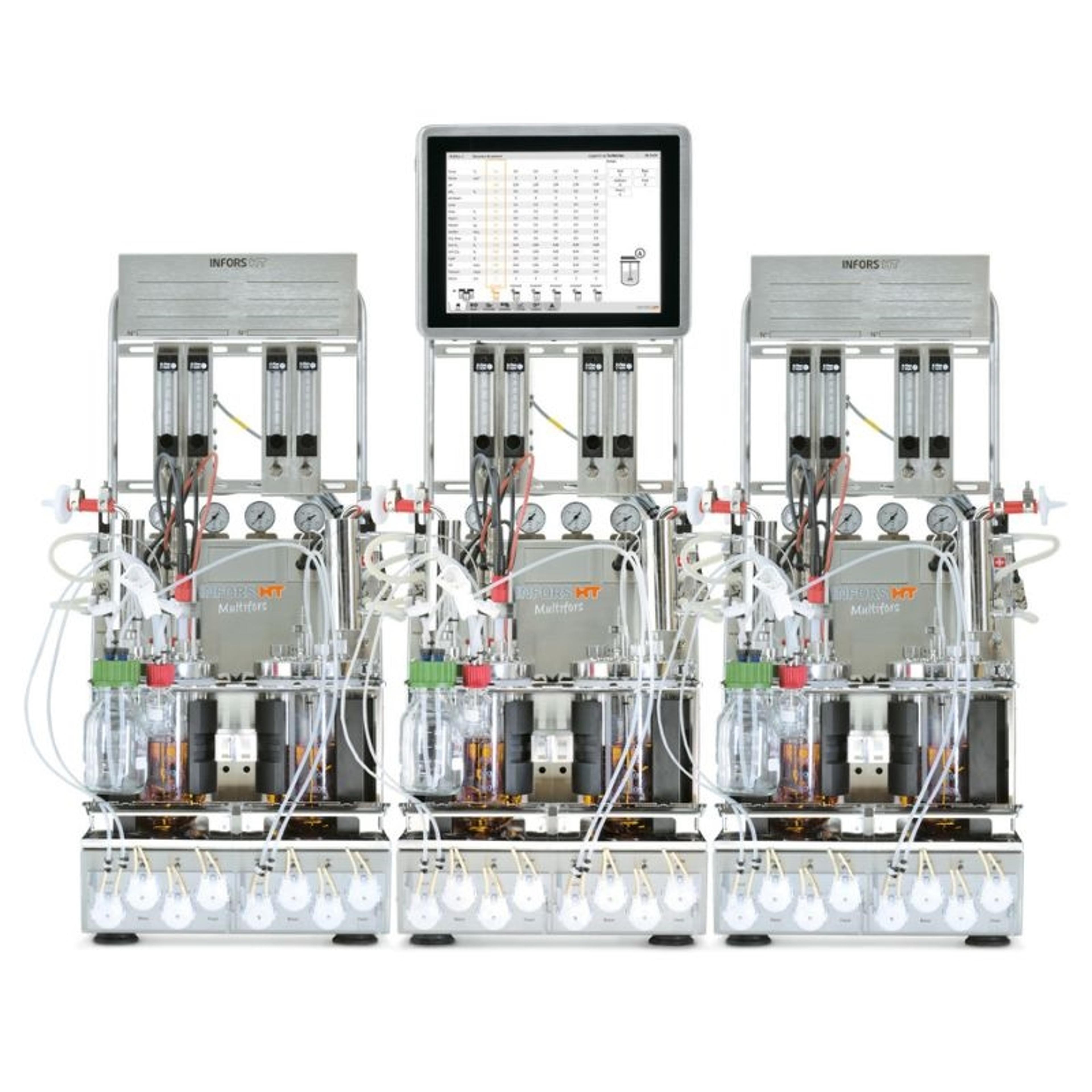

Multifors 2

Multifors 2 Bench-Top Bioreactor: Up To Six Culture Vessels On Three Base Units

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Must have for fermentation research

Biomanufacturing R&D

The control this biorecator provides is perfect for fermentation R&D. It always functions as intended and the data collection is solid.

Review Date: 14 Apr 2023 | INFORS HT

With Multifors 2 you can work with up to six bioprocesses in parallel. Thanks to a selection of preconfigured packages and a variety of connection possibilities and options, you will be ideally equipped for optimizing sophisticated bioprocesses on a small scale.

The Multifors 2 is a compact, free-standing device with up to six culture vessels on three base units. To give you more flexibility in the lab, we have organized the vessels into groups of two that you can separate, recombine or expand however you like. The integrated touchscreen controller lets you see all of your bioprocesses at a glance and control all of your culture vessels.

Multifors Features:

Fully equipped:

An integrated analog feed pump is a standard feature that makes the Multifors Bioreactor immediately ready for fed-batch cultures. The unit includes three digital pumps for acids, bases, and antifoaming agents. Up to four gases (air, N2, O2 and CO2) can be used in virtually any combination. Users can select either a mass-flow regulator or a rotameter for a precise feed.

Developed for scale-up:

The Multifors Bioreactor offers you fully functional bioreactors on a small scale, employing the same sensor technologies as larger bioreactors and consequently delivering directly comparable data. Optional PAT tools offer you a simple way of preparing for later production in a benchtop or pilot-plant reactor.