Heterogeneous Catalysis Workflow

Efficiently design, synthesize, characterize and screen libraries of catalyst materials by combining custom hardware and software capabilities. Create and test hundreds of heterogeneous catalyst materials per week using a variety of fully automated techniques. The automated nature of the workflows increase reproducibility and provide a complete experimental record. Prepare: Synthesize diverse arrays of heterogeneous catalyst…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

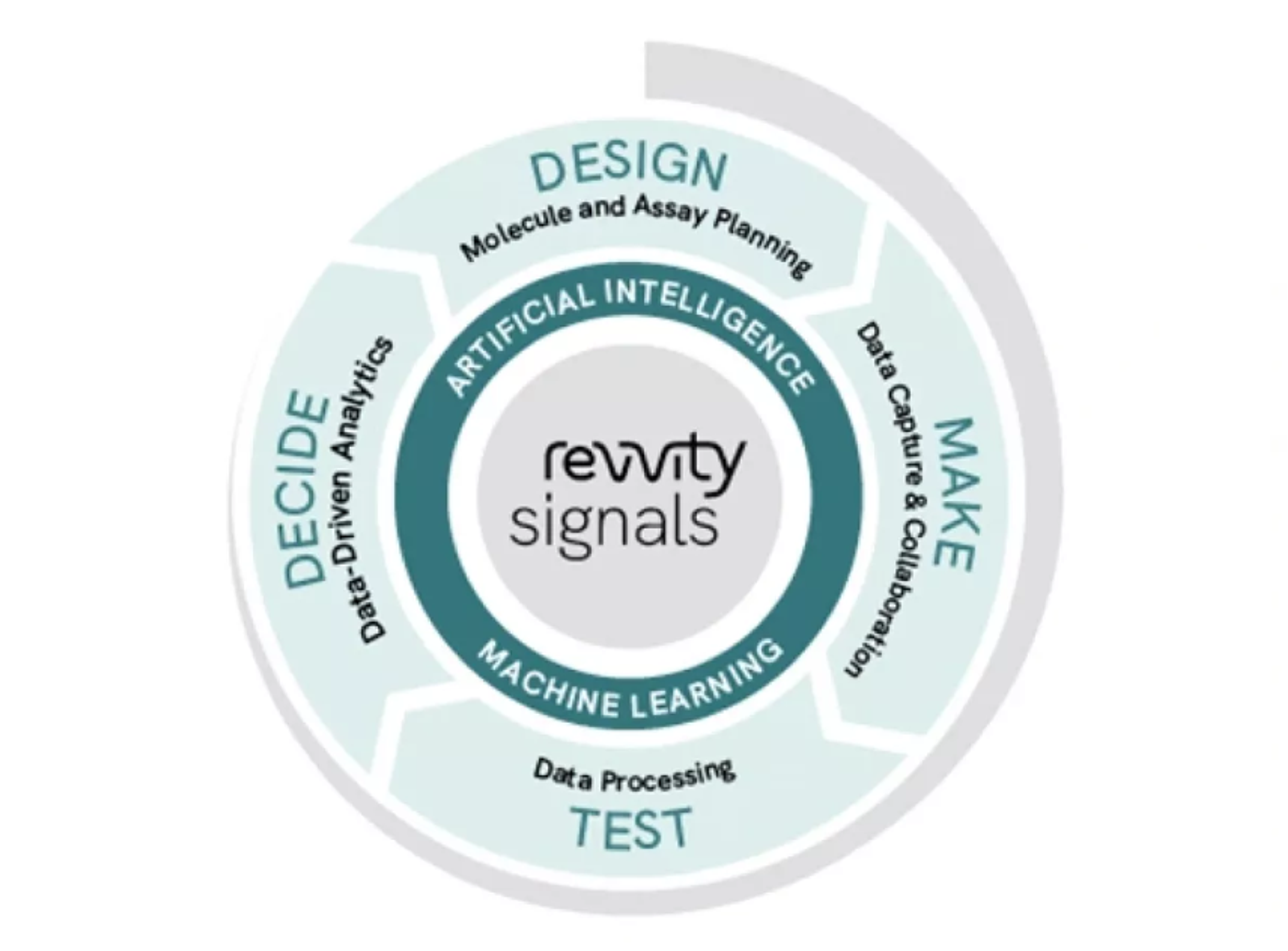

Efficiently design, synthesize, characterize and screen libraries of catalyst materials by combining custom hardware and software capabilities.

Create and test hundreds of heterogeneous catalyst materials per week using a variety of fully automated techniques. The automated nature of the workflows increase reproducibility and provide a complete experimental record.

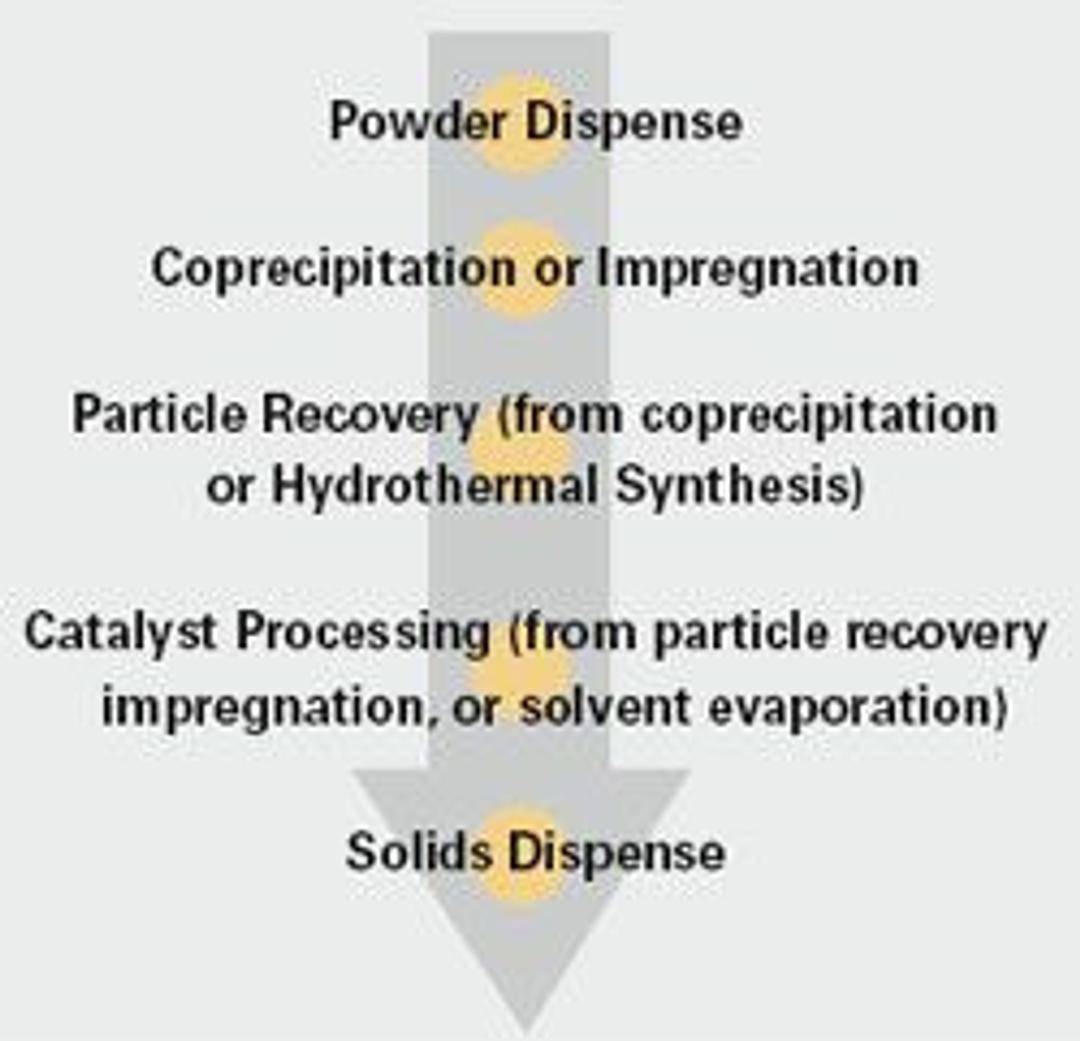

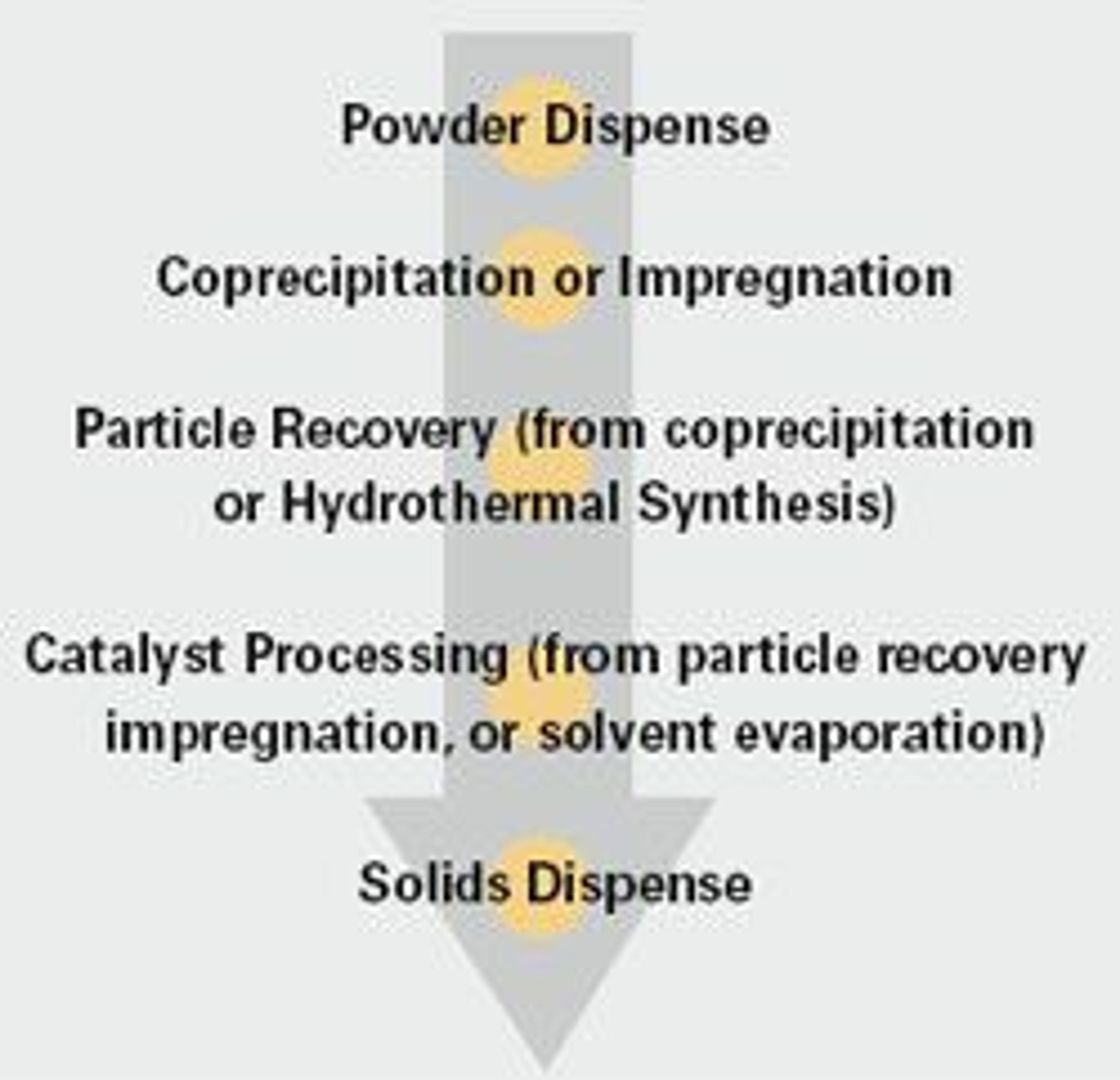

Prepare: Synthesize diverse arrays of heterogeneous catalysts

- Rapidly explore complex compositional phase spaces.

- Prepare hundreds of samples per week with any one of several automated synthesis tools.

- Tools are available for impregnation, coprecipitation, hydrothermal synthesis, sol gel synthesis and solvent evaporation.

- Flexible hardware and software allows easy modification and rearrangement of elementary steps in a synthesis.

Process: Modify heterogeneous catalyst materials using automated techniques

- Calcination, reduction and other pretreatments (ex situ and in situ)

- Mechanical treatments such as grinding, pilling, sizing

- Washing and ion exchanging

Analyze: Correlate catalyst performance, physical properties and synthesis

- Analyze samples by XRD, SEM, EDS, BET, XRF, and ICP by integrating third party hardware as part of a workflow.

- Rapidly explore complex process phase spaces.

- Screen 48 samples simultaneously in a multi-channel fixed bed reactor with full product analysis and mass balance. With pressures up to 2000 PSI, temperatures up to 650ºC, with a reaction zone temperature accuracy of +/-.5ºC, and a flow split accuracy of <1% RSD.

- Screen 24–96 samples simultaneously in a parallel liquid phase batch reactor at up to1500 PSI and 450ºC.