How to streamline your (q)PCR workflows through automation

Catch up on this expert webinar to learn how to improve throughput and result quality in PCR and qPCR workflows

18 Aug 2020

Dr. Stefanie Navabi, PCR Product Manager, Analytik Jena AG

PCR is a well-established technology that is used as a gold standard technique in life science research and disease diagnostic applications. In recent years, the demand for high-throughput analysis while maintaining excellent data quality and reducing the risk of human pipetting errors and external contamination is increasing.

The integration of (q)PCR thermal cyclers into robotic systems to develop a fully automated workflow allows scientists to generate tens of thousands of data points per day without adding to their personal workload.

In this webinar, Dr. Stefanie Navabi, PCR Product Manager at Analytik Jena AG, outlines how Analytik Jena can support customers to easily accelerate throughput. Analytik Jena’s (q)PCR thermal cyclers are designed to offer a fast and flexible integration into robotic systems to help ensure an error-free 24/7 operation. This significantly reduces project times and saves costs through reduced hands-on time, accelerated data generation and greater plate-to-plate consistency.

Watch on demand

Catch up on this webinar to discover:

- Key drivers for automation of PCR and qPCR

- Solutions for automated PCR and qPCR

- Product overview and integration strategies

Read on for highlights from the live Q&A session or register to watch the webinar at any time that suits you.

Q: Can the instruments also be operated as standalone devices?

SN: Yes. For both instruments, a separate computer software is available with which the instruments can be controlled completely independently from an automation system.

Q: Is it possible to integrate devices with different block formats into a liquid handling system simultaneously?

SN: Yes. For the software, it doesn't matter if you integrate a 96-well or a 384-well instrument. From a practical or application view, in most cases, the block formats are not mixed on a platform, but if it's needed, then yes – it's possible.

Q: Are there exchangeable blocks for the devices?

SN: No, that's not possible. For both instruments, the blocks are mounted in a fixed form. That means for each block format, you will need a separate instrument.

Q: Can several devices be integrated into one robotic system?

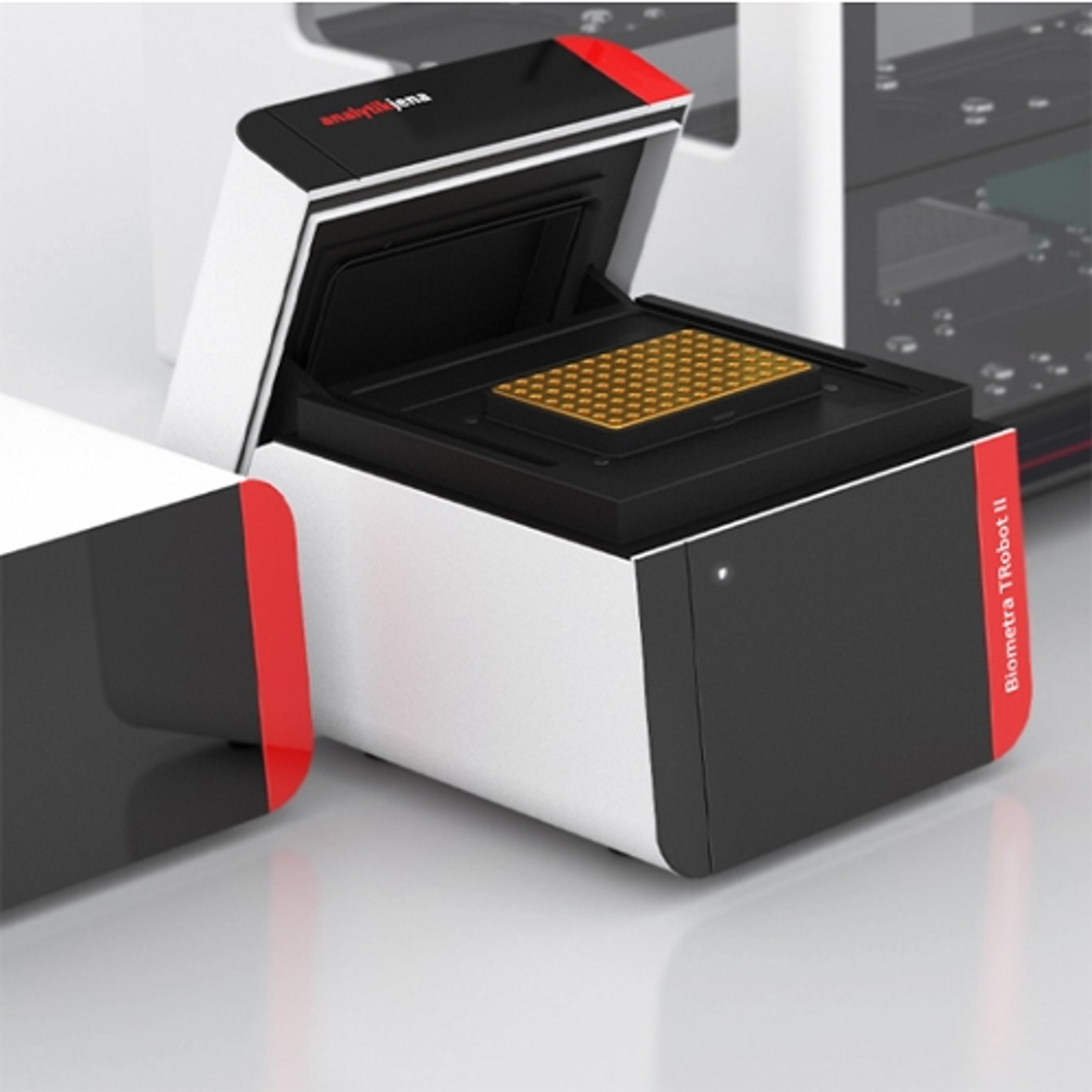

SN: Yes, this is possible. For the real-time PCR instrument, the qTOWER3 auto, the integration of up to four instruments in one automation system is possible. For the standard PCR instrument, the Biometra TRobot II, the number of instruments that can be integrated is not limited from the software side; theoretically, up to 1,000 devices can be controlled by the software. This means the user is free to choose the number of devices according to the application and the space.

Q: Which interfaces can be used for the integration?

SN: This will depend on the instrument. For the qTOWER3 auto, the interface is a USB connection or Ethernet. For the Biometra TRobot II, you can choose from a serial interface, RS232, and Ethernet. Additionally, by the use of a USB to RS232 adapter, you can also use USB too – meaning there are three options possible.

Q: For which automated liquid-handling platforms have you developed drivers for integrating the TRobot II?

SN: The Biometra TRobot II and the qTOWER³ auto are both open platforms. We didn't develop drivers specific for certain liquid handling platforms, but we have developed universal drivers which can be used for integration in any liquid handling platform software. The driver software is made available to integrators. They can then do the integration with this software and documentation. In case of questions we are at their disposal as support. At the moment, we are in contact with some important liquid handling suppliers, and we have already provided them with a test instrument and the software, so that they can prepare the integration. In summary, the integration has to be done by the liquid handling supplier.

Q: Can the TRobot II be run without an integration as a standalone thermal cycler? If so, do you need to connect it to a computer? How would you go about doing this?

SN: Yes. Both instruments can be used with a separate software. Such software is available for both systems, and you will need a computer. It's very simple to work software, so it's also possible to use these instruments without an integration.

Q: Can the CyBio FeliX be adapted for negative pressure and HEPA filtrations for infectious samples?

CyBio FeliX can be equipped with a UV/HEPA hood or placed in a PCR workstation.

Q: Is the nucleic acid extraction and PCR setup taking place in the same chamber? If so, how is the risk of contamination mitigated?

SN: This depends on the user, but from our point of view we recommend that to use two different devices. These steps should not take place in the same chamber otherwise there could indeed be a risk of contamination.

Q: What is the minimal volume a pipette can pick up in CyBio FeliX?

The minimum volume is 1 µl.

SelectScience runs 3-4 webinars a month across various scientific topics, discover more of our upcoming webinars>>

Do you use Analytik Jena products in your lab? Write a review today for your chance to win a $400 Amazon Gift Card>>