Biomaterials: Shining a new light on bone disease

Prof. Silke Christiansen describes how she explores the mechanical properties of bone to help better treat osteoporosis and highlights the technological advances enabling new insights

23 Nov 2020

In this exclusive interview, we speak with Prof. Silke Christiansen, department leader at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS, in Bavaria, Germany, to find out how her expert team of materials and computer scientists, physicists, biologists and engineers is using correlative microscopy and spectroscopy to obtain a deeper understanding of osteoporosis and therapy. Christiansen discusses the potential behind correlative microscopy and spectroscopies and how her collaboration with ZEISS has helped to achieve her research goals by providing and integrating new analytical tools and workflows to best suit her needs, whilst highlighting how she aims to make a significant impact in the field of biomedical research.

Advances in materials science

The materials we use have a significant impact on our daily lives and play a vital role in energy use, transportation, health and beyond. Prof. Silke Christiansen and her team are at the very forefront of work to enhance the world’s understanding, knowledge and use of materials which can be of inorganic or organic nature. “My specialty is correlative microscopy, as well as spectroscopy for all sorts of materials, devices and biomedical research,” says Christiansen. The Fraunhofer Institute carries out a vast range of work, predominately focusing on battery and fuel cell materials all the way to device integration. But the institute, with close to 800 people in various areas of Germany, addresses more, such as the use of ceramic technology in biomedical implants, sensing devices and protective glass-ceramics for cellphones and vehicles to name just a few developmental areas. “Our research for various groups at IKTS is centered on the structural, compositional and functional characterization of aforementioned materials and devices, which requires the use of a variety of microscopes that image with electron-, ion-, x-ray or laser beams, as well as spectroscopic analytical tools.”

Tremendous advances in microscopy in recent years have made it easier for researchers to study, image and characterize materials than ever before. Despite this, there are still setbacks to overcome. “Working with complex materials with structures of scale-bridging nature, i.e., from macro to nano, was never as inspiring as it is today,” Christiansen tells us. “Nowadays we have fantastic analytical capacities that are specifically designed to tame complex material architectures with precision and control at the nanoscale, and for that, we rely on excellent images that are possible today with the highest magnifications.” In regards to current challenges, she adds: “The main difficulty we are facing is being able to extract more out of a sample than just a bare image of its surface and this often means combining all information and data from various different imaging and spectroscopic modalities to catch a comprehensive set of different physical properties, e.g., electrical, optical, structural, compositional, mechanical, topographic, etc. to generate the best possible understanding of a material or device.”

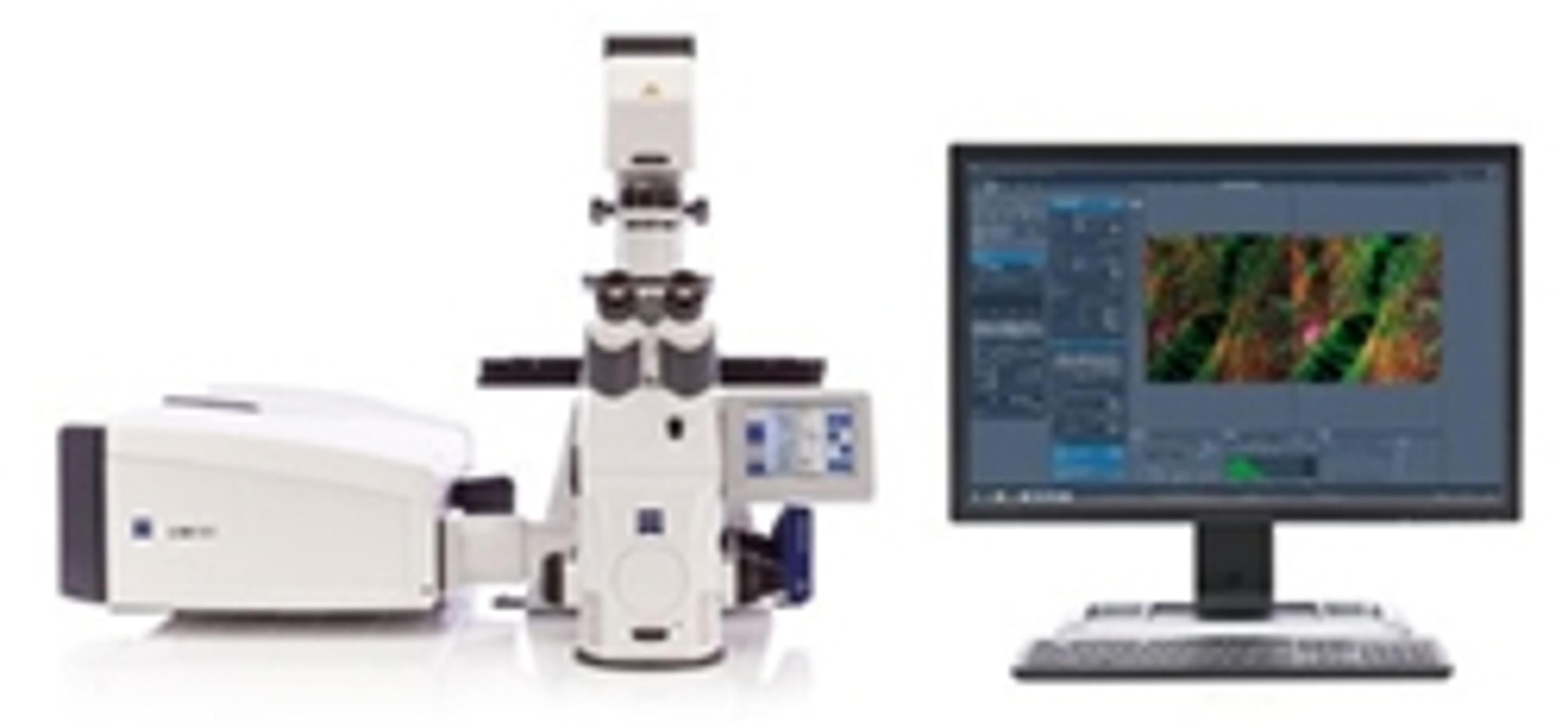

The materials science of bone

Christiansen leads a whole range of scientific and technical projects offering very often her expertise in materials science and solid-state physics. However, when it comes to the extraction of quantitative and statistical information out of microscopy and spectroscopy data, the gained knowledge can easily also be applied to biomaterials and so she decided to use the skillsets of her team to better understand how to treat bone disease. “The biggest project I am involved in right now is a grant from the European Commission in the Excellent Science priority - ERC, where we obtained an ERC Synergy Grant ‘4D+-nanoscope’ together with two scientists (Prof. Dr. med. G. Schett, Prof. Dr. – Ing. A. Maier) from the Friedrich-Alexander-University Erlangen-Nürnberg (FAU) in 2019. Within this ERC funding scheme, we recently installed a combination of ‘bleeding-edge’ analytical tooling including an X-ray microscope of type ZEISS Versa 620 which permits tomographic analysis of materials, as well as a Zeiss laser scanning microscope – LSM 680/Airy Scan which permits best-in-class fluorescence microscopy,” says Christiansen. “We are applying these and other analytical tools such as state-of-the-art scanning electron microscopes but also more unique and sophisticated imaging and analytical machines, such as, for example, a ZEISS helium ion microscope with sector field mass spectrometer, which is one of three currently existing machines of this type, particularly suited to image and analyze non-conducting materials such as bone. Using healthy controls and osteoporotic bone with and without treatment and therapy, usually taken from mouse models provided by our medical partners, we can perform the so far most comprehensive analytical (various microscopy and spectroscopy modalities), scale bridging dataset and as such contribute to an improved level of understanding osteoporosis and other bone diseases.” The team hopes their project will make a significant impact and encourage more clinicians to team up with scientists of other disciplines. “This project is not a typical materials study because we are analyzing biological tissue, however, bone is as material-like as it gets in biology.”

Christiansen goes on to explain why bone is not so different from technological materials: “Whether you work with biological materials or technological materials, bone still has a hierarchical structure which contains fine structures such as vessels and pores at different scales forming scale-bridging networks. For example, a network of pores (in which bone cells reside) in bone, is very similar to a pore architecture in a ceramic material; both determine the bulk mechanical properties of the volume material.” There are clearly strong similarities that exist between bone and technological materials. “In our transdisciplinary ERC team we are aiming to establish new approaches based on comprehensive analytics together with quantitative and statistical data evaluation, including new approaches of machine learning, to guide clinicians towards better-personalized treatment and therapy of osteoporosis,” says Christiansen.

AI and the quest for data

To perform its cutting-edge work, it is essential the Fraunhofer team has access to the latest and most advanced equipment: “We use a range of different microscopy and spectroscopy instruments from manufacturers such as ZEISS, to help us ensure we gain a detailed insight into the materials we are exploring,” says Christiansen. As part of its work, the team employs mouse models, with the aim to soon be able to reduce the usage of animals via artificial intelligence (AI). AI will help the researchers make the most of their data while using as few animals as possible: “The power of artificial intelligence and algorithmic statistical evaluation has never been so important as it is today. When you combine microscopy and spectroscopy, you can generate a huge amount of heterogeneous data without as many animals.” Christiansen goes on to explain that microscopy is not just about generating images, but also extracting data: “We invest a lot in improving our expertise in performing statistical data evaluations, as well as machine learning and deep learning approaches to extract much more out of an image or a dataset than we could ever do before.” Christiansen’s team combines microscopy, spectroscopy, and many other different imaging modalities to generate a comprehensive picture and extract quantitative information. “By combining different imaging and analytical modalities,” she says, “we generate much more comprehensive information, and this equipment is made available by manufacturers such as ZEISS.”

Exploring a whole new world

The development of the microscope has enabled scientists to achieve new insights down to the nanoscale in many disciplines, from materials science to microbiology. Correlative microscopy and spectroscopy is a collection of complementary techniques that help researchers explore their samples in more detail: “Correlative analytics has opened a whole new world as soon as we combined more rigorously different microscopes and additional analytical modalities,” Christiansen explains. “For instance, if we have a sample the size of a €2 coin and we manage to locate an interesting nanoscale particle on its surface, we can physically take the sample and transfer it to another machine to perform, for example, Raman spectroscopy, i.e., a form of molecular fingerprinting. As well as this, we can go further and also carry out X-ray fluorescence imaging or Fourier transform infrared spectroscopy or time-of-flight mass spectrometry.” By combining all these techniques, scientists can discover the functionality as well as the mechanical, electrical, optical, structural and other properties of the material.

ZEISS knows what the next big thing in science is

Prof. Silke Christiansen Fraunhofer Institute for Ceramic Technologies and Systems IKTS

The partner of choice

Christiansen and her team have chosen to collaborate with ZEISS to help fulfill their research objectives. “We have been applying local scanning microscopes, as well as the ORION NanoFab Helium Microscopy system from ZEISS. When I formed my research group, I used a handful of microscopes from all different manufacturers. I now realize the advantage of using many tools from one key manufacturer,” says Christiansen. “ZEISS knows what the next big thing in science is. I have found that the people working for ZEISS are really interested in your work and make tools available to you, such as additional analytical add-ons.” Christiansen highlights how ZEISS was able to successfully integrate a Raman spectroscopy system with their electron microscope: “This integration was on our wish list and ZEISS did a marvelous integration. ZEISS is very open-minded, and the company showed that they want to work at the cutting edge of all new applications within the microscopy field and they have their eyes wide open when customers convey their technological needs.”

Future outlooks

Looking ahead, Christiansen and her team plan to continue developing and expanding their lab through collaboration with ZEISS as they work to break scientific boundaries. “There is always a new piece of kit on our wish list and we will continue to work with ZEISS,” says Christiansen. “I hope to achieve funding in order to integrate our microscopes with other analytical modalities for faster comprehensive data collection.” Christiansen also expresses her hopes to continue to investigate bone diseases and establish new analytical workflows and pathways to guide clinicians on a solid ‘bleeding edge’ analytical base towards better therapies and treatments.