The standard-setting approach to viral vector manufacturing in CGT

16 Oct 2025Cell and gene therapy (CGT) is entering a sustained growth phase, powered by the promise of treating disease at its genetic root. In this landscape, vector production is the key bottleneck: to scale reliably, developers standardize protocols and use stacked multilayer chambers for high-density adherent cell culture, expanding surface area while keeping growth on target.

The day-to-day challenge is visibility and timing. In multilayer formats, growth varies by layer and region, yet monitoring still relies on opening the incubator for spot checks. That causes temperature and CO₂ shifts, increases handling-related contamination risk, and leaves operators with subjective assessments. Harvest timing and subculture decisions then default to judgment rather than data, undermining batch comparability, slowing investigations, and raising the risk of missing the optimal window. Researchers need continuous, inside-the-incubator visibility of morphology and confluency, captured as standardized records across shifts and sites—and this is where Celloger® Stack fits.

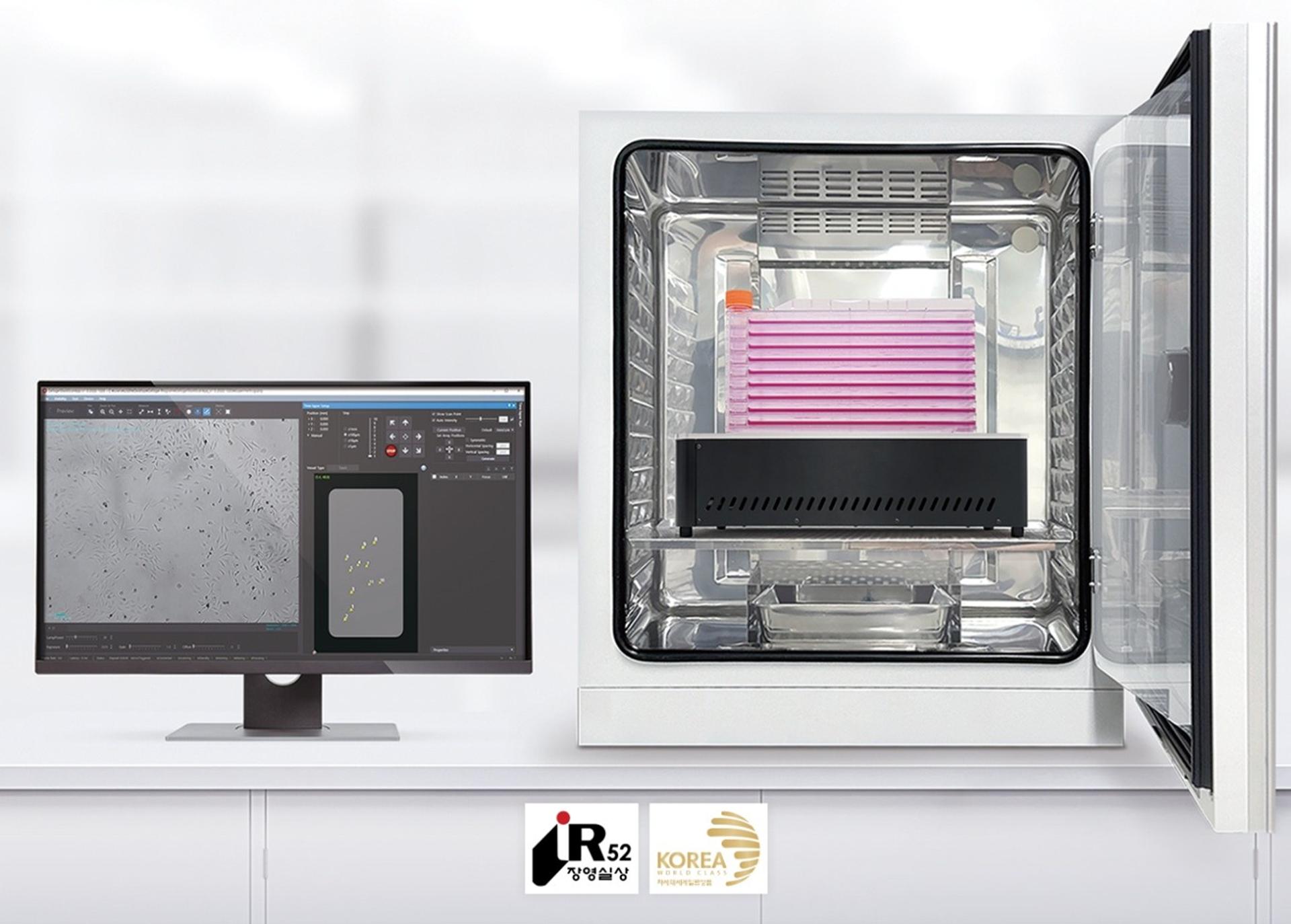

Designed for vector manufacturing in multilayer vessels, Celloger® Stack keeps monitoring inside the incubator, maintaining stable conditions while improving visibility. It brings observation to the vessel by automating scheduled, multi-position brightfield imaging and generating confluency-over-time graphs, so growth is tracked continuously and harvest can be called at the right moment—without opening the door. By minimizing handling and keeping temperature, humidity, and CO₂ stable, Celloger® Stack supports consistent conditions from seed train through scale-up.

Key features of Celloger® Stack

Real-time multilayer monitoring inside the incubator

Celloger® Stack acquires brightfield images without moving the vessel, keeping temperature, humidity, and CO₂ stable. Rather than occasional snapshots, researchers can monitor morphology and growth continuously over hours or days. This reduces handling, lowers contamination risk, and supports right-first-time performance across runs.

Multi-position, scheduled time-lapse with a motorized camera

A motorized camera moves across predefined coordinates at set intervals. Each frame is time-stamped and automatically compiled into time-lapse clips for quick review. The result is a time-resolved map of cell expansion across the vessel that makes trends, regional differences, and early issues straightforward to spot —and to compare across operators, shifts, and sites.

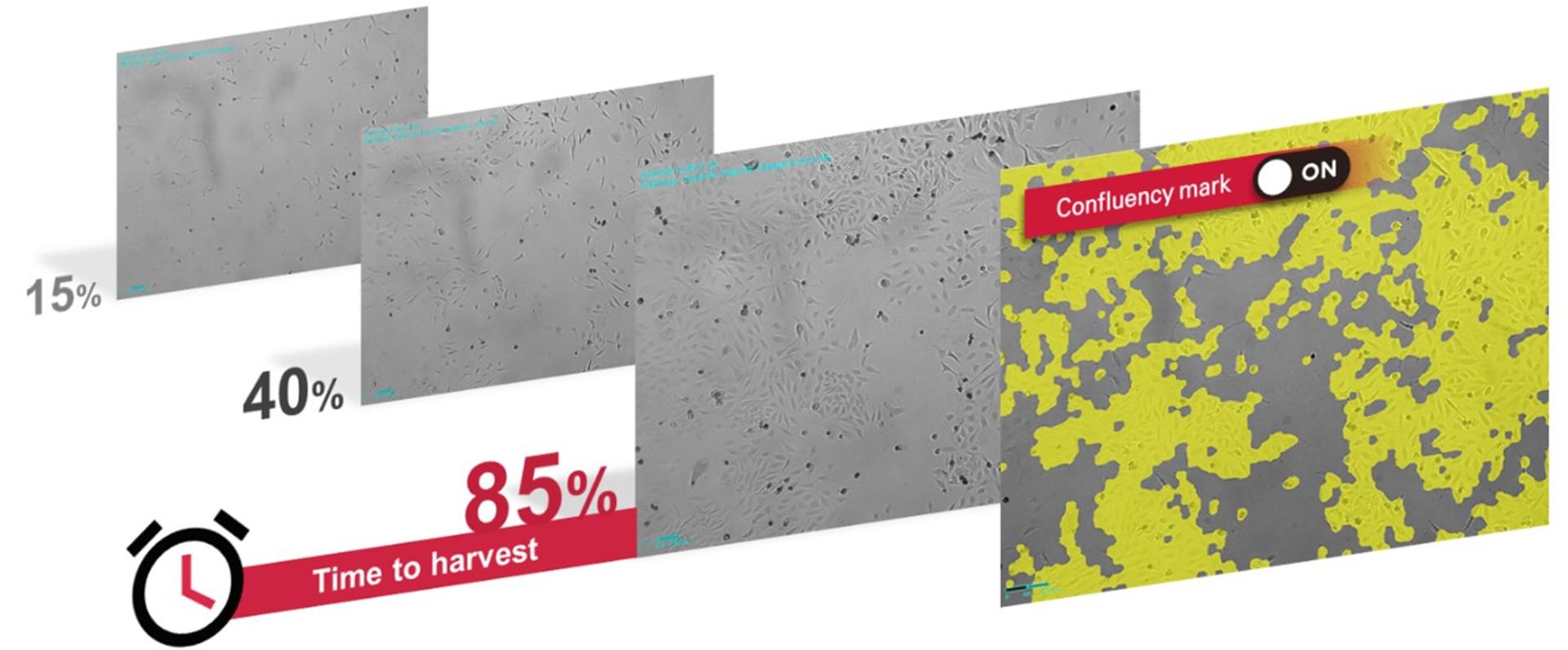

Quantitative confluency analytics for objective harvest timing

The analysis software measures cell confluency over time and presents it as clear graphs. Researchers can set SOP thresholds—such as “split at 70%” or “harvest at 85%”—to keep growth within target ranges and avoid over- or under-growth. Decisions become faster, more consistent, and grounded in quantitative measurements.

Interchangeable vessel holders for diverse formats

Swap-in holders fit common multilayer chambers and can be customized for dishes or flasks. This modular setup lets groups adopt Celloger® Stack without redesigning their workflow, accelerates validation, and supports unified monitoring as pipelines progress from seed trains to scale-up and routine production.

Conclusion

As CGT programs scale, vector production in multilayer vessels succeeds only when researchers can see enough, early enough—without disturbing the culture. Celloger® Stack provides that visibility by keeping monitoring inside the incubator and combining scheduled, multi-position imaging with confluency-over-time analytics. The impact is immediate: steadier conditions, earlier deviation detection, objective harvest timing, and an audit-ready record that extends from seed train to scale-up and commercial manufacturing. Celloger® Stack helps sponsors and CDMOs alike deliver reproducible, high-quality vector batches from multilayer cultures.