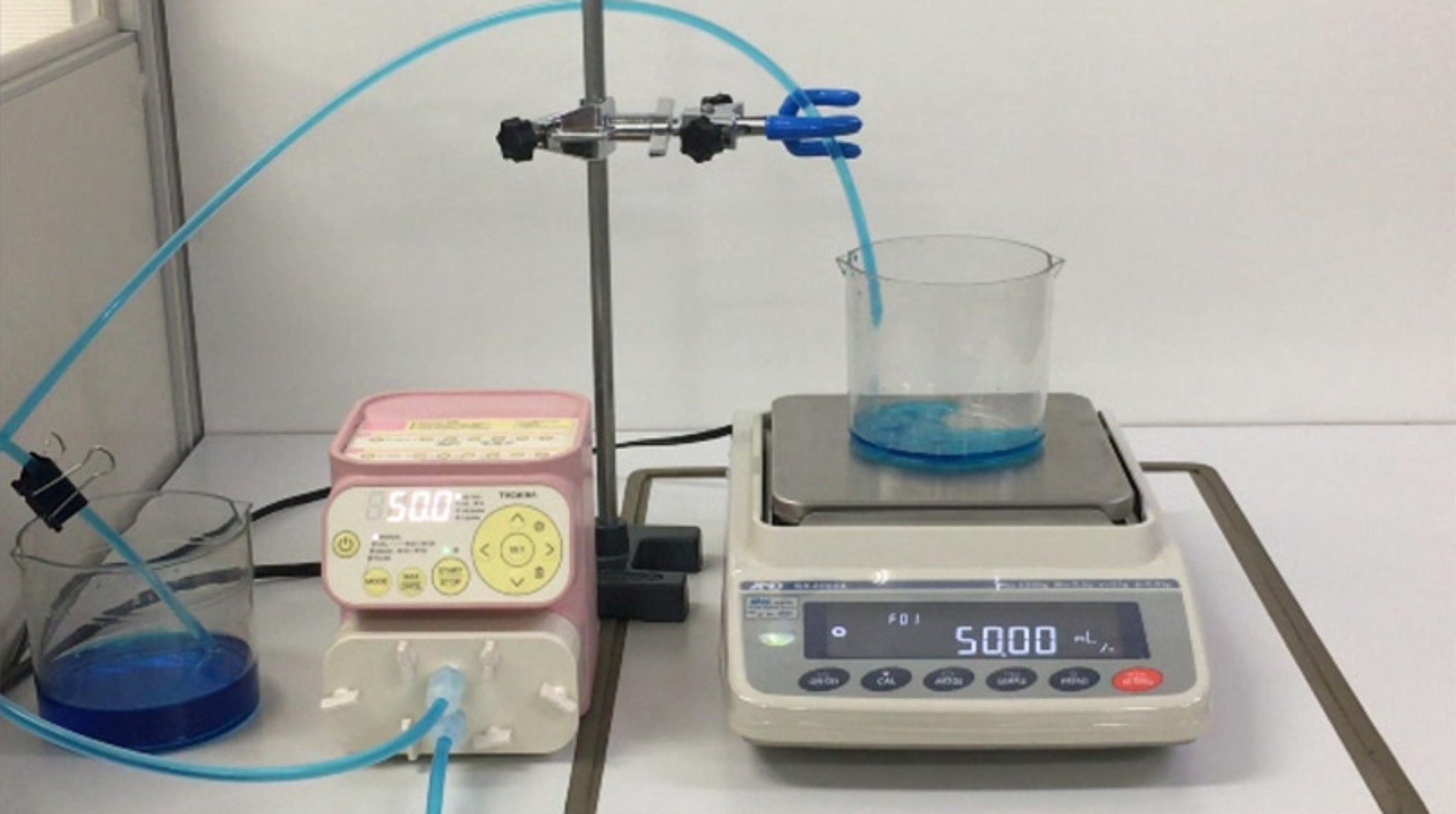

Flow Rate Display: Streamline & Improve Filling or Dosing Accuracy & Precision

13 Nov 2018

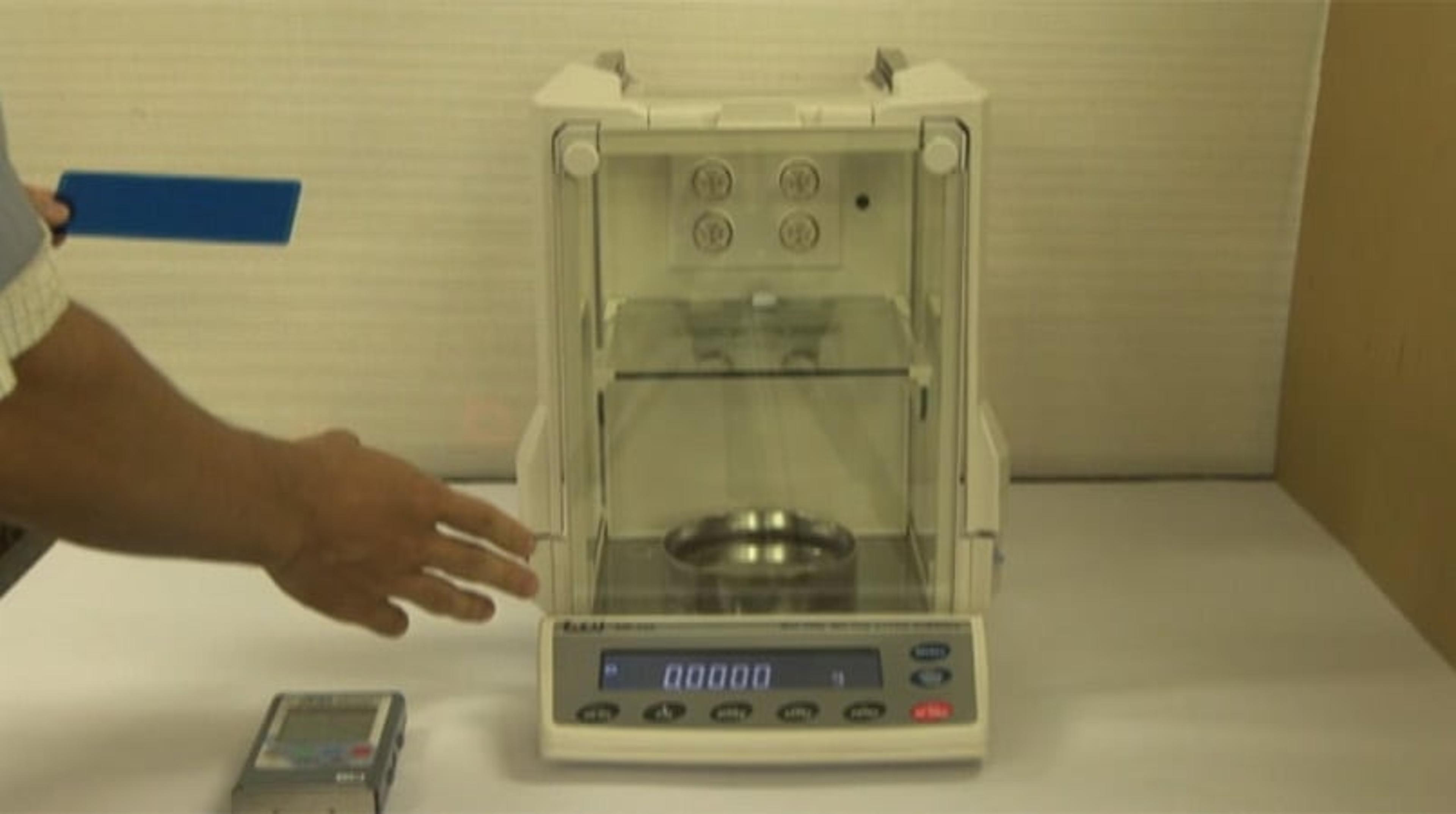

Many operators use a stopwatch or PC to determine a flow rate. Flow Rate Display (FRD) helps to streamline and improve both by offering a synced solution that improves accuracy and precision in filling or dosing applications. For example, the internal clocks of external devices are never in complete sync with precision balances. Therefore there is a time-clock disparity that is most noticeable when measuring and recording flow rates of pumps, feeders and other devices at short intervals. Command speed and refresh rate will cause the PC to intermittently produce irregular values or spikes even if the actual flow rate is constant. The Apollo series through an FR-Cal function calculates, displays, & outputs (WinCT-FRD) the mass flow rate, or the volume flow rate by entering the density of the material. Up to 10 densities can be saved to the device. Both the display refresh rate and interval (set between 1 second and 1 hour) are regulated by the same internal clock of the balance, making measurements free from the irregularity that rise from time clock disparity problem.