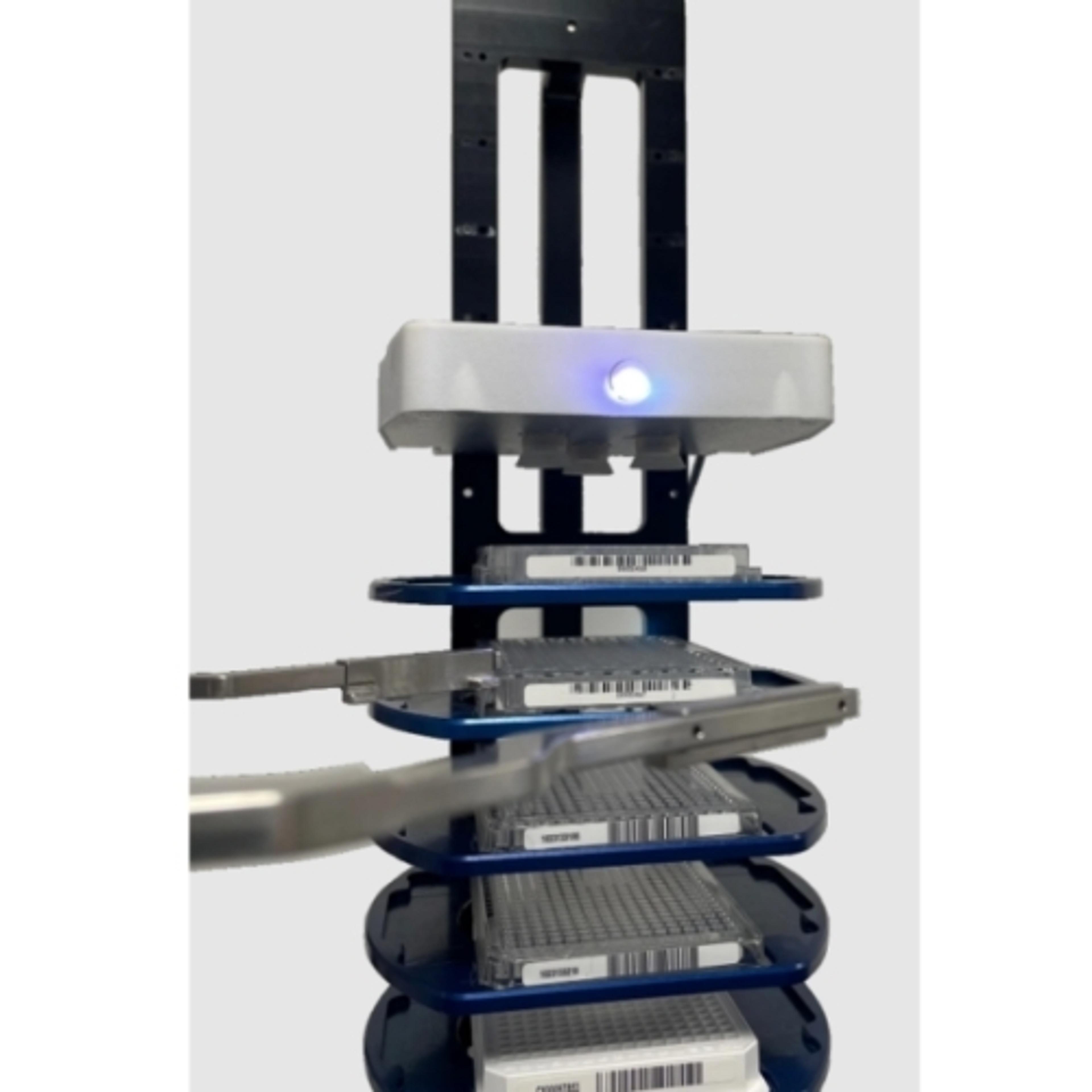

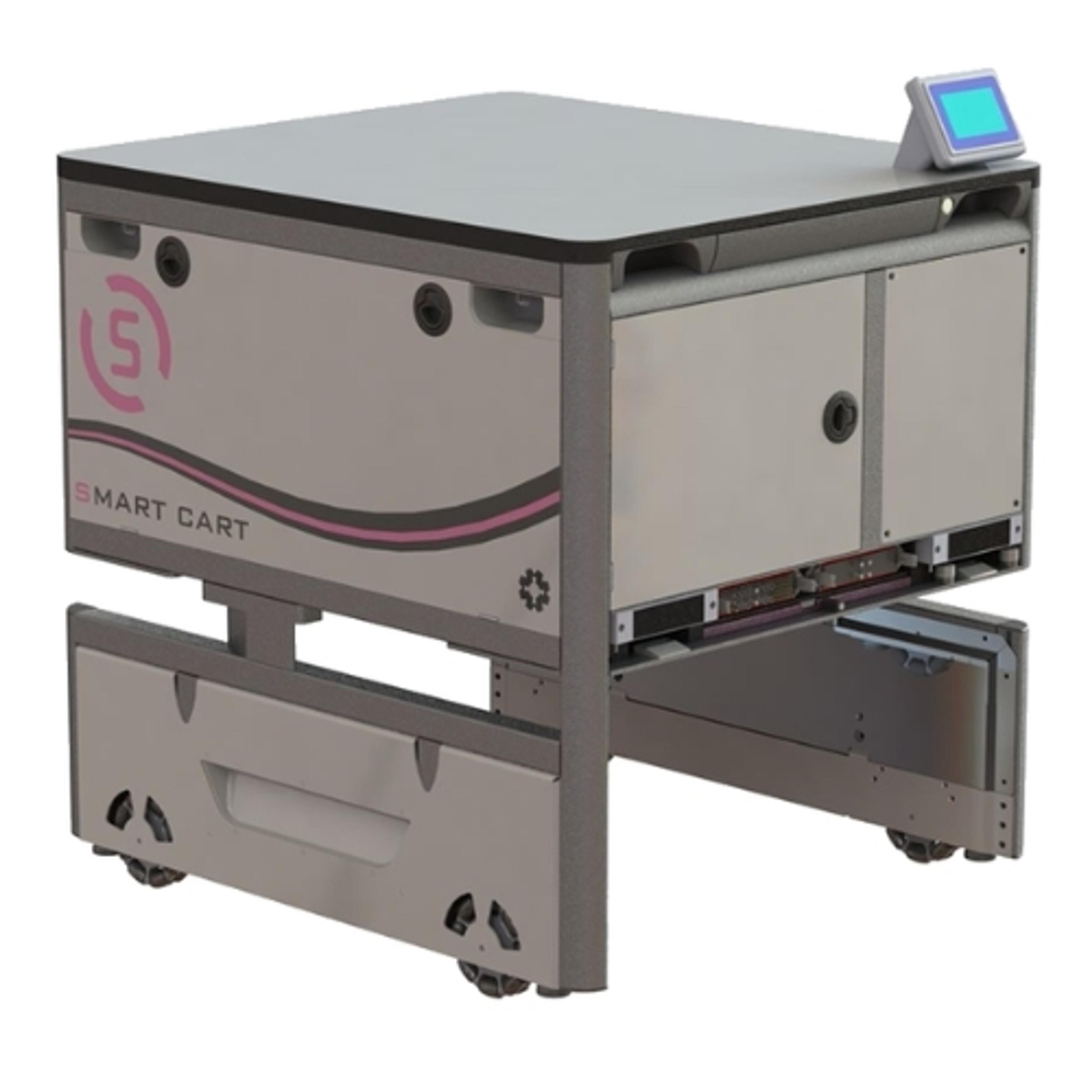

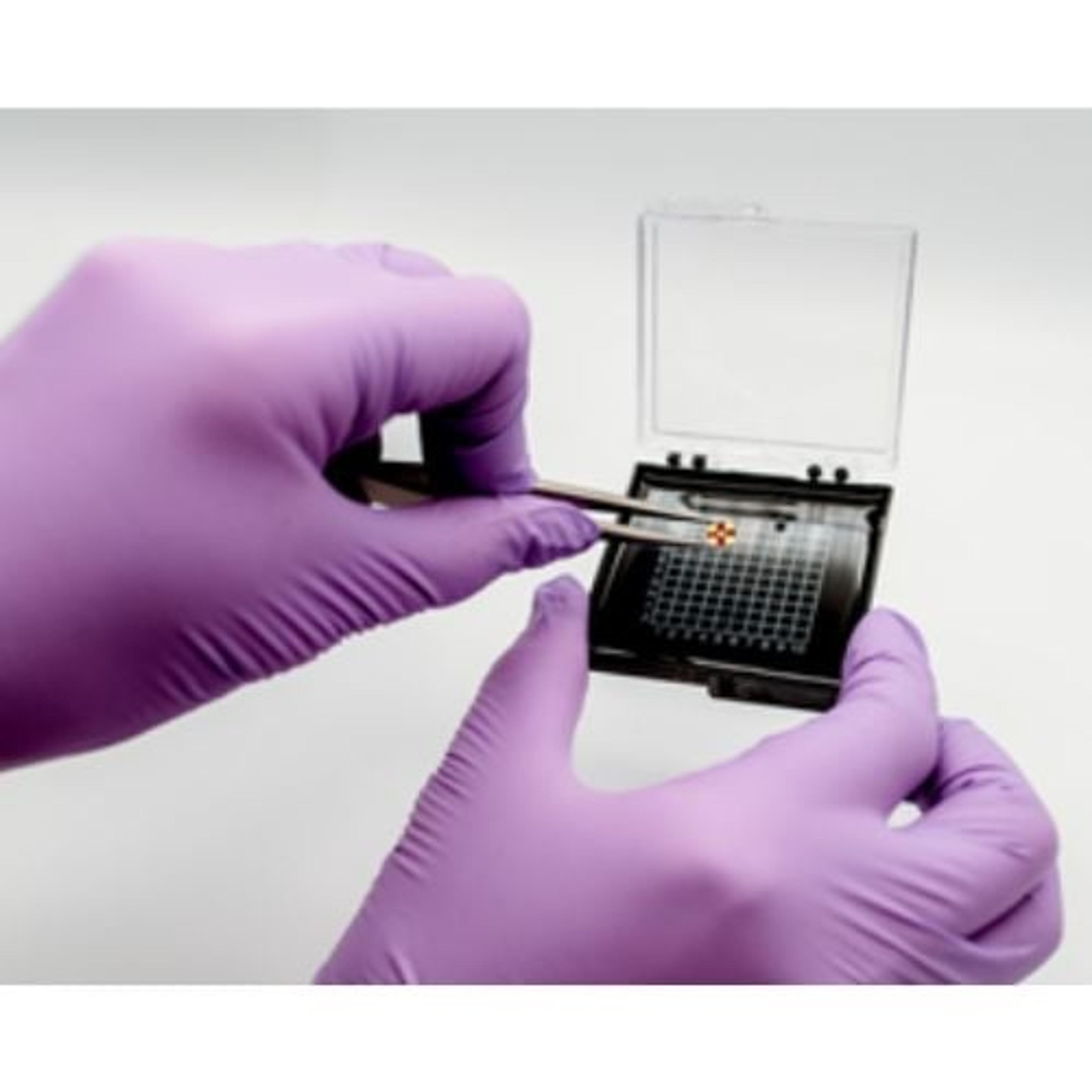

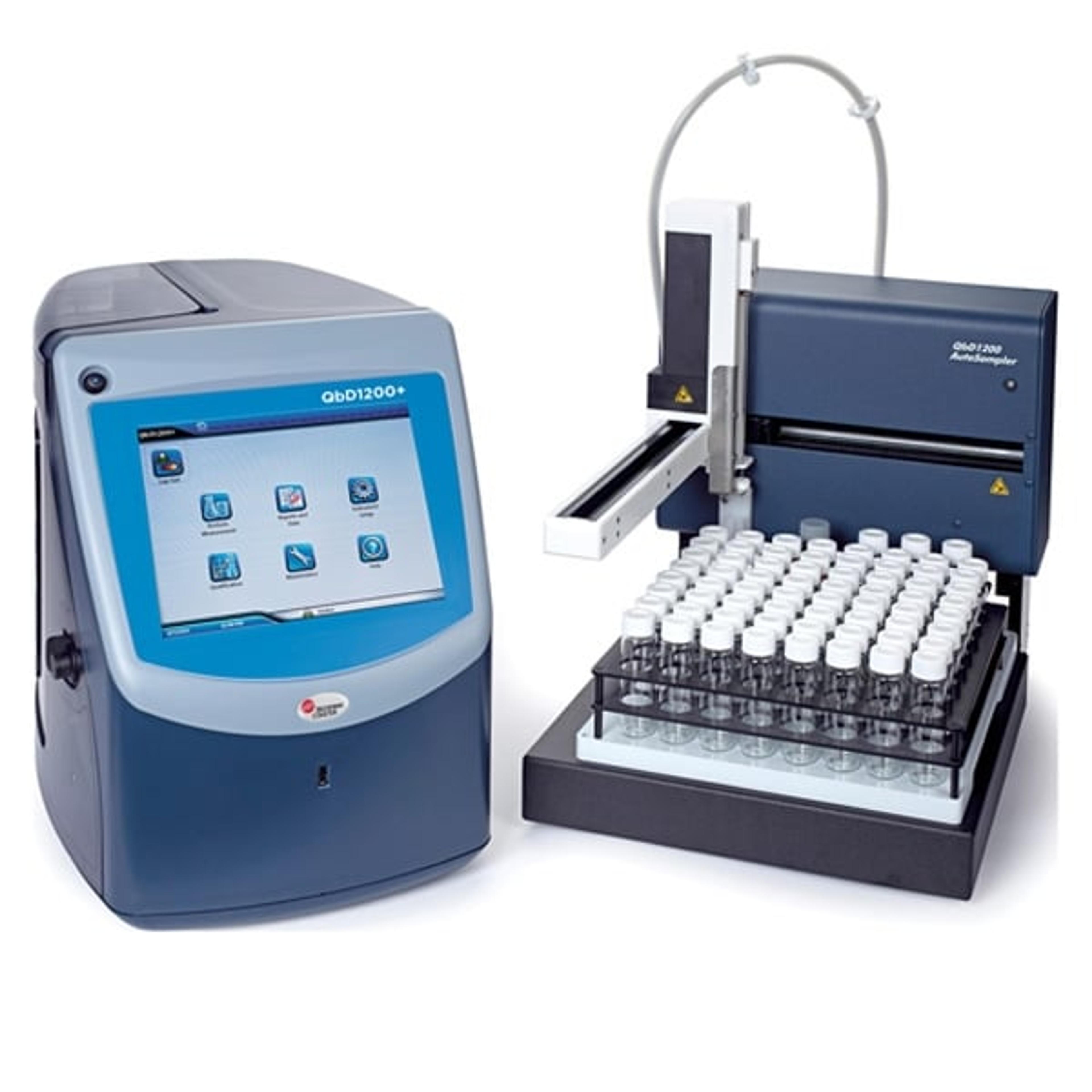

D-LID laboratory microplate delidder

Peak Analysis and Automation LtdThe D-LID laboratory microplate delidder promises to be smarter, greener, and more versatile than any comparable product on the market. Simple functionality, easy installation/setup, and great performance.