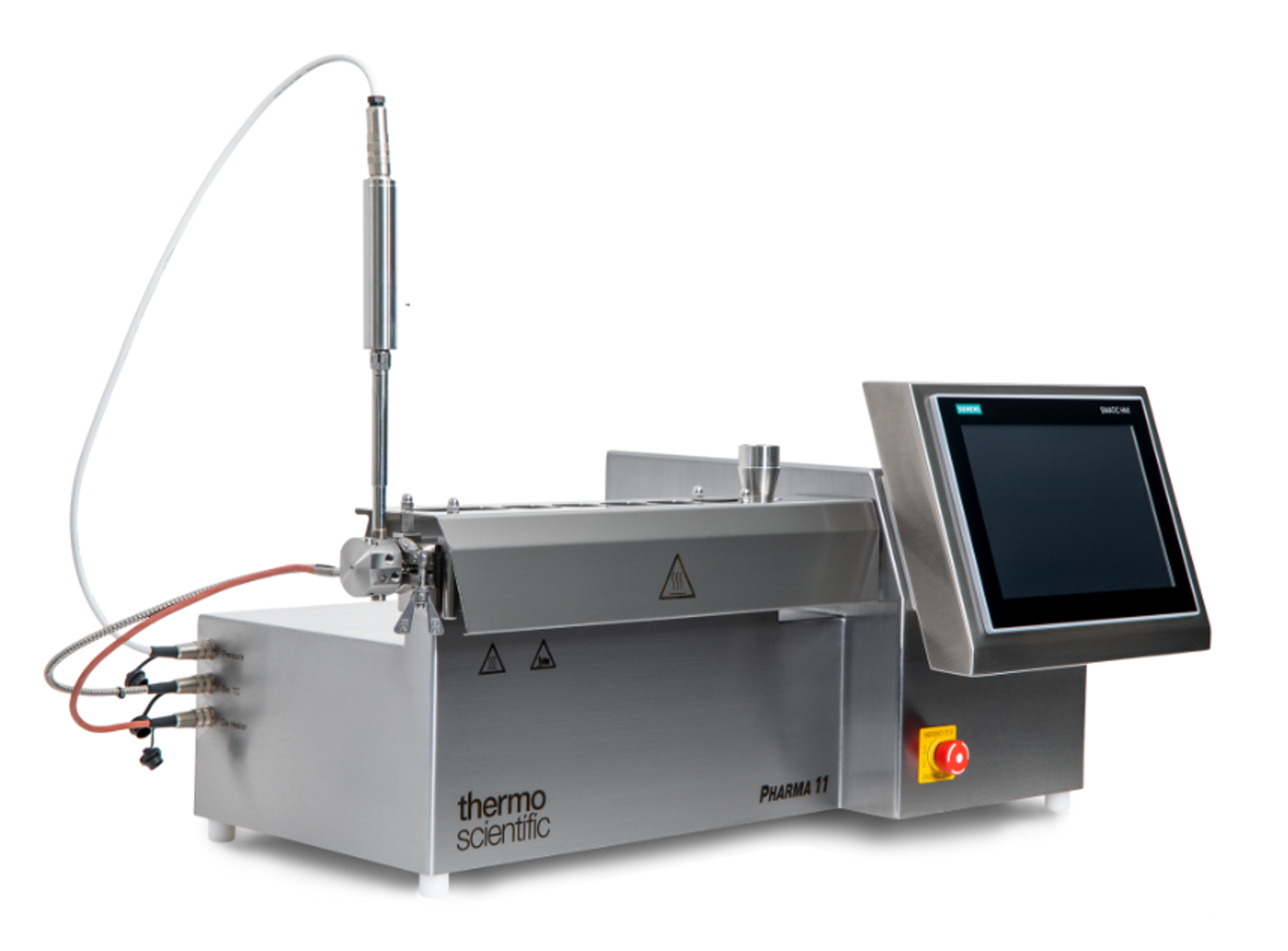

Thermo Scientific™ Process 11 Parallel Twin-Screw Extruder

Twin-screw extruders are well-established and used in a wide variety of food, polymer, and pharmaceutical applications to efficiently develop and produce high-quality products using a continuous process. The modularity of the Thermo Scientific™ Process 11 Twin-screw extrusion equipment provides great flexibility in designing a process to accomplish your food process development goals.

A small footprint reduces lab space requirements and lower ingredient consumption reduces environmental contamination and operator exposure. Tailor the product quality characteristics of starch based products, flavorings or meat analogues.

The Process 11 Parallel Twin-Screw Extruder is designed with a user-friendly touch-screen operation that features an integrated feeder control and easily removable product contact parts. The compact monocoque design minimizes the usage of lab space and is ideal for fume hood applications. The screw elements and barrel design scale geometrically across all Thermo Scientific extruders and allow easy process scale-up.

The Process 11 Parallel Twin-Screw Extruder Features:

- Minimized sample material usage (20 g)

- Throughput range 20g/h to 2.5kg/h

- Small footprint bench top design that is easily transportable

- Segmented screw design with removable top half barrel

- Easy-to-operate touch screen with integrated feeder control

- Geometrically scalable screw and barrel design across portfolio

Recommended for:

Materials:

- Polymers

- Additives

- Adhesives

- Food

- Cosmetics

Applications:

- Compounding

- Masterbatches

- Nanocomposites