The Ultra Centrifugal Mill ZM 300

The Ultra Centrifugal Mill ZM 300 provides fast and gentle homogenization of solid sample materials

Quality instrument with good user experience.

Protein digestibility

High quality of product from the instrument, fast processing time, easy to use and clean!

Review Date: 7 Dec 2022 | Retsch GmbH

It does the job well.

particle size reduction

Highly effective, easy to use, high quality product

Review Date: 7 Dec 2022 | Retsch GmbH

Quality product

Grinding bulk bone for production of dental bone

This is a sturdy product

Review Date: 7 Dec 2022 | Retsch GmbH

Love this equipment, very reliable. Customer service is lacking.

Finished poultry feed and ingredient sample prep

This grinder performs wonderfully. We have had ours close to 5 years and have not had an issue. We grind anywhere from 300-500 samples per week. However, in that 5 year span I have never been contacted personally by a Retch Rep for follow up or maintenance check.

Review Date: 7 Dec 2022 | Retsch GmbH

This is a good investment for Lab sample prep equipment

Animal Feed and Fertilizer

This is best grinder in our Lab. We also have others brand, but the Retsch Mill is a top ranking. All stainless-steel parts are very easier to clean.

Review Date: 7 Dec 2022 | Retsch GmbH

Must have equipment

ingredient technology

This equipment is a must have for ingredients science and application laboratories. Easy to use, low maintenance and safe to operate. It provides reproducible results.

Review Date: 7 Dec 2022 | Retsch GmbH

Consistent results, the best grinder for high oil content seeds

Analysis of oilseeds and grains

The Retsch Ultra centrifugal mill (I used the ZM 200 for many years) is the one “grinder” that gave us the particle size and hence the best analytical result (e.g. oil content) in a variety of oilseed sample types. Unless the sample is ground to a consistent and fine particle size, without unbroken seed particles the subsequent oil extraction process will not be complete. This same principle is important for industrial scale extraction. Proper sample preparation leads to maximizing oil extraction. Over 30 years in the laboratory, allows me to call the Retsch mills/ grinders as the “gold standard” when it comes to sample preparation.

Review Date: 7 Dec 2022 | Retsch GmbH

Great results

Culture medium for mites

Very good design, easy to use and easy to disassemble. This is very important for the complete cleaning of the different pieces. Highly recommended for medium quantities of material.

Review Date: 17 Aug 2022 | Retsch GmbH

Great instrument, easy-to-use and reliable. I love it so much, thank you Restsch.

Sample prepration

Great

Review Date: 11 Aug 2022 | Retsch GmbH

I can't live without ZM300

Pharmaceutical industry

The product is easy for use

Review Date: 11 Aug 2022 | Retsch GmbH

The Ultra Centrifugal Mill ZM 300 is a high speed rotor mill with unmatched performance. It is used for the rapid size reduction of soft to medium-hard and fibrous materials.

The variable speed from 6,000 to 23,000 rpm allows for gentle preparation of analytical samples in a very short time. Thanks to an integrated temperature monitoring system, reproducibility is guaranteed even for long grinding processes or pulverization of large sample volumes.

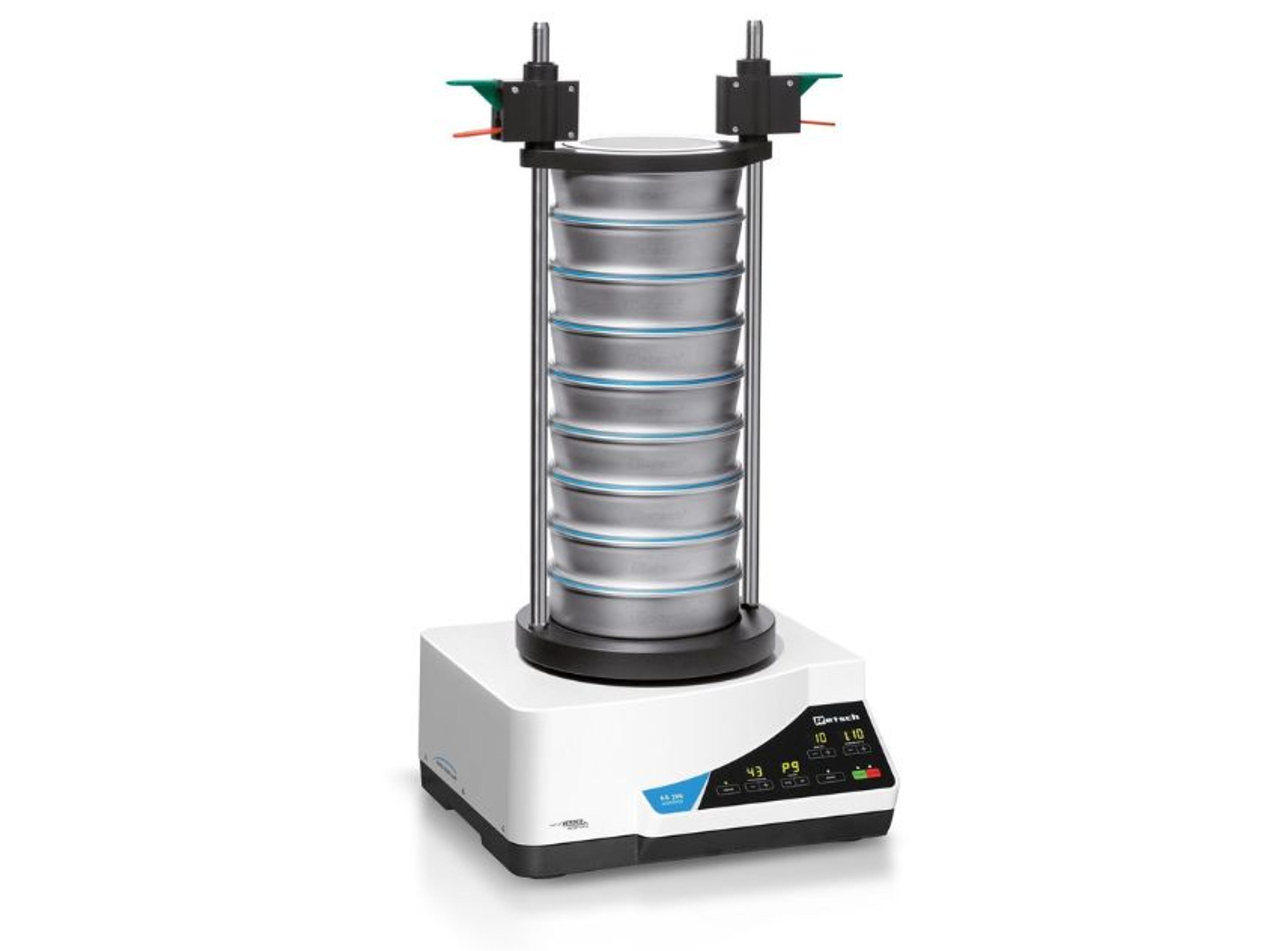

The comprehensive range of accessories including a large variety of ring sieves and rotors as well as collection systems makes the Ultra Centrifugal Mill a versatile instrument that can be easily adapted to varying applications.

The optional Vibratory Feeder is load-controlled via an interface and ensures a uniform grind at maximum output rate. When using a cyclone, the sample material is additionally cooled by the air stream and more rapidly discharged from the grinding chamber via the cassette pan with outlet. This effect can be increased by connecting a vacuum cleaner.

With thousands of installations, the ZM series has become a standard for food and feeds, for the chemical industry as well as for agricultural testing.