Lynx Robotic Liquid Handling Platform

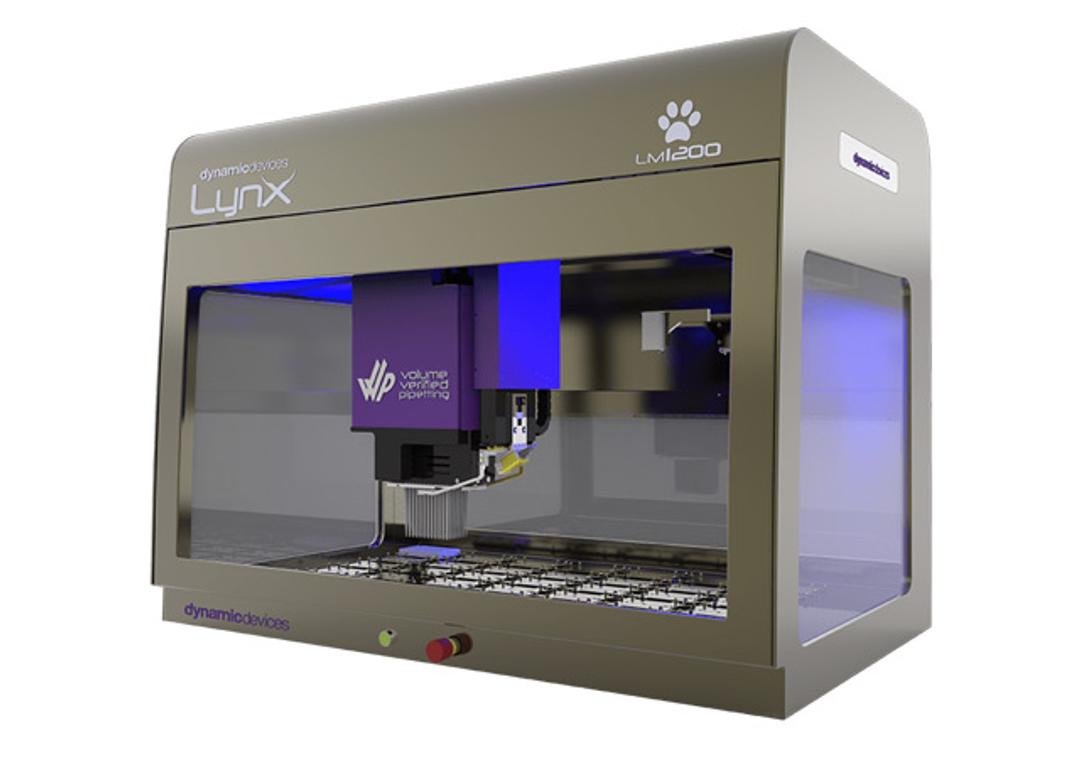

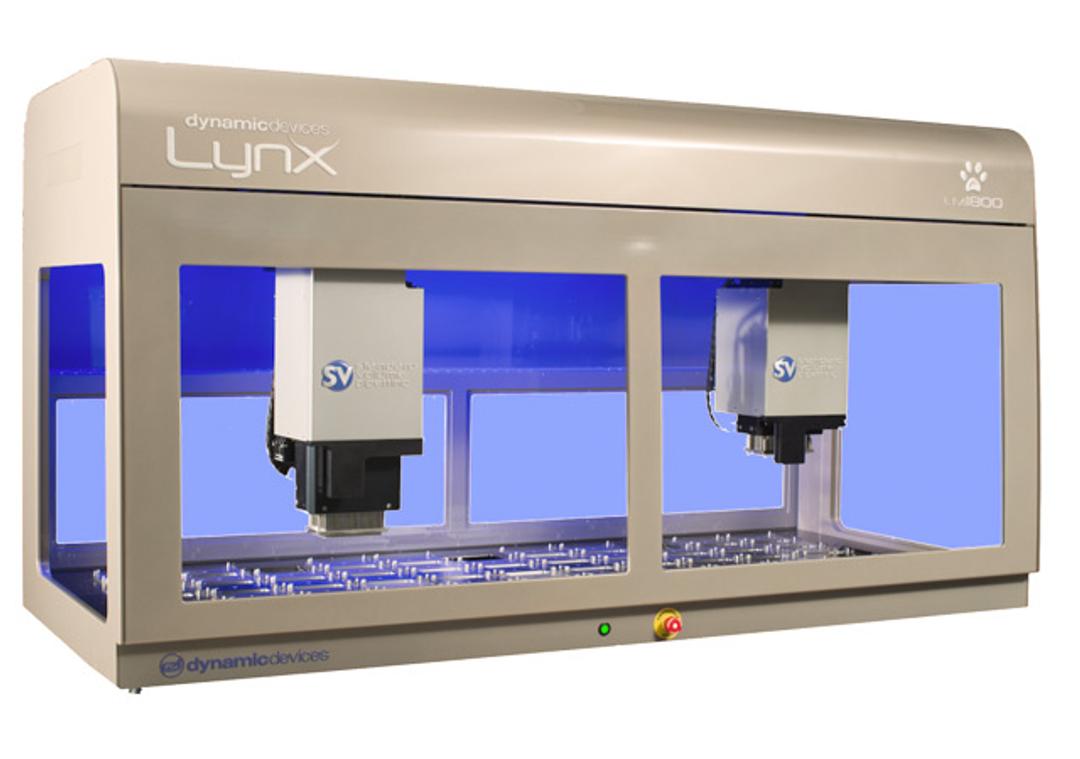

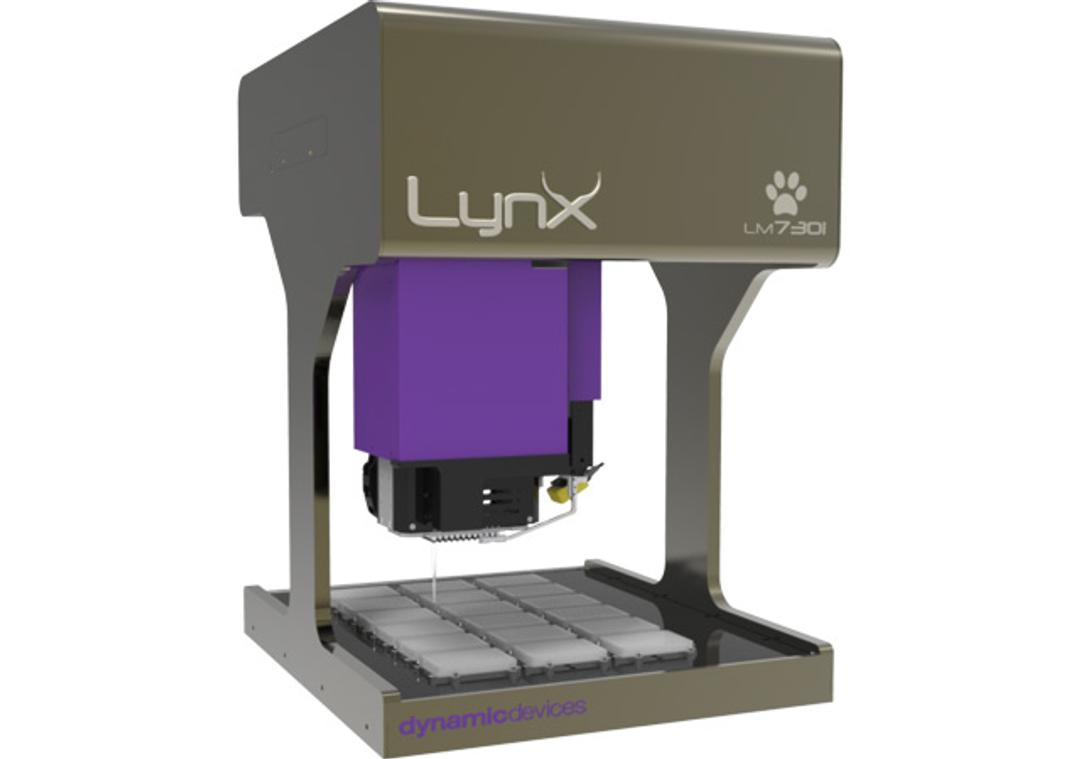

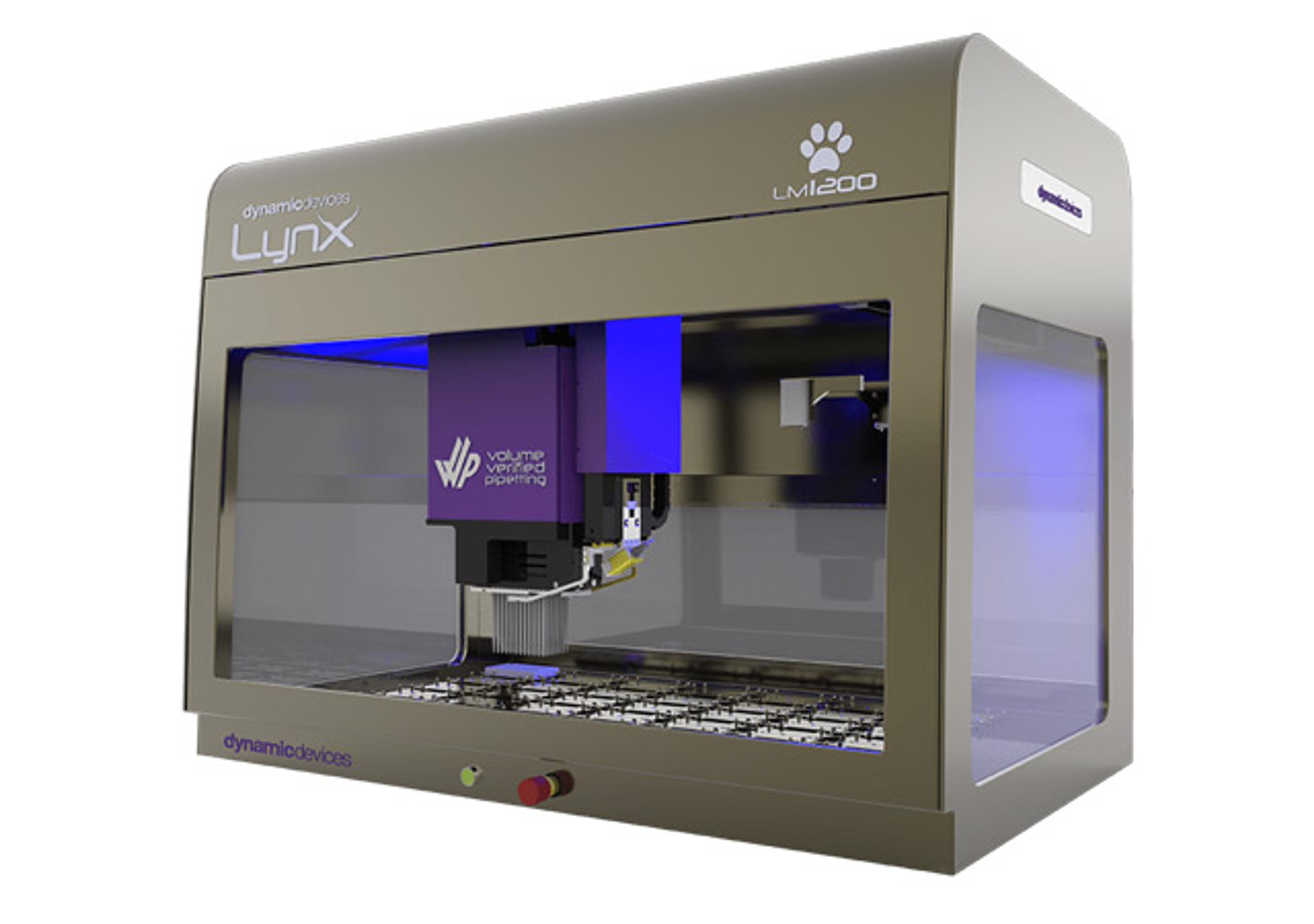

The Lynx Robotic Liquid Handler—available in LM1800, LM1200, LM900, LM730i, and LM700 models—features Standard Technology (ST) pipetting tools, rapid on-the-fly tool swapping, and award-winning Volume-Verified Pipetting (VVP). With linear-motor motion and flexible deck designs, it delivers unmatched precision, throughput, and workflow integration.

Great instrument, technical support and service

PBMC isolation from whole blood

The Lynx 1800 has worked great in purifying PBMCs from whole blood. They made custom parts to aid us in developing our automated process. Their technical support and the equipment have been excellent. Highly recommend!

Review Date: 4 Feb 2019 | Dynamic Devices

The Lynx Robotic Liquid Handling Platform empowers life science labs with automation that adapts to your needs—available in LM1800, LM1200, LM900, LM730i, and LM700 models. Each platform is built on Dynamic Devices’ advanced linear-motor motion system and ultra-flexible deck configurations, providing unmatched precision, throughput, and workflow integration.

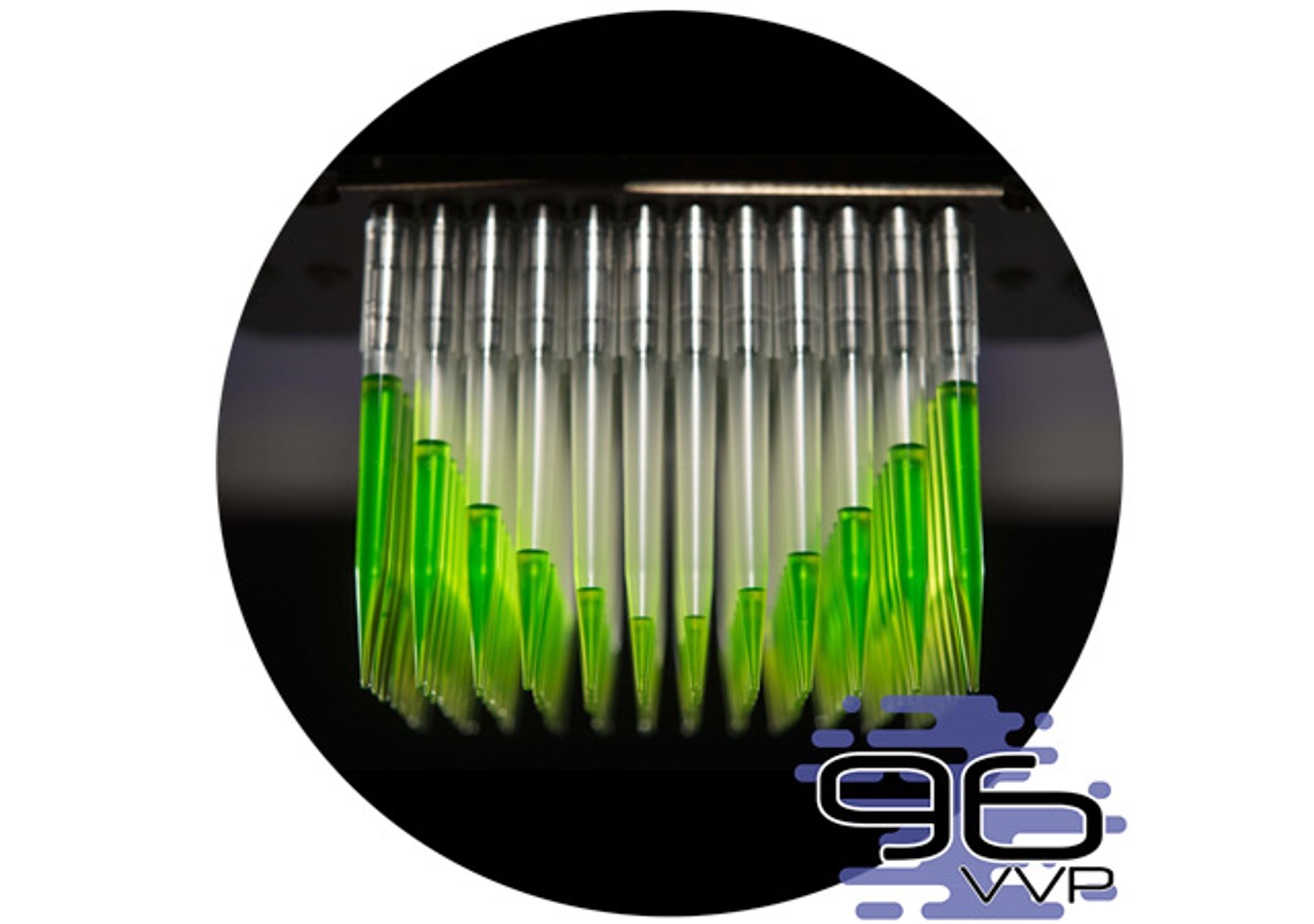

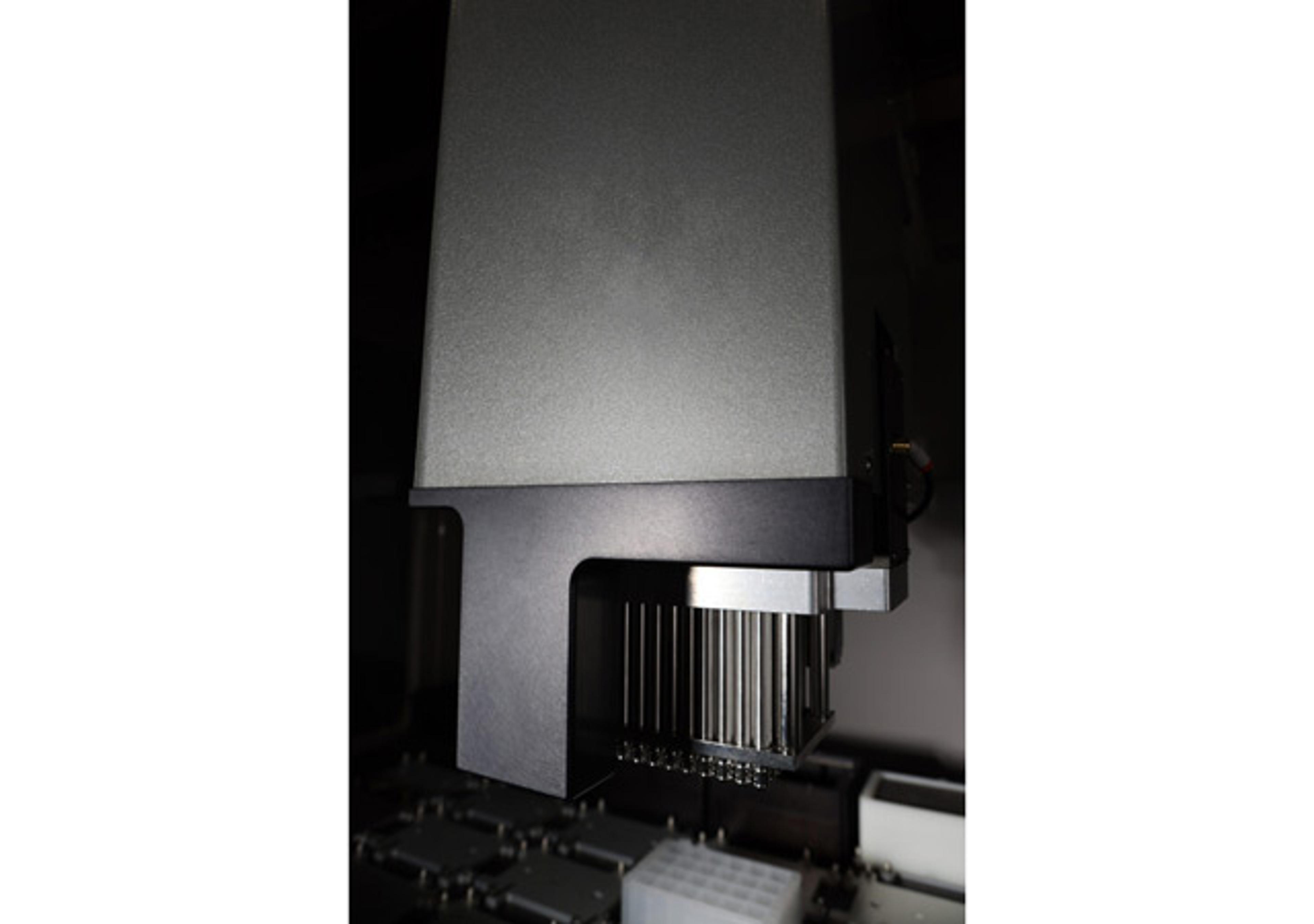

At the core are two powerful pipetting technologies. Volume-Verified Pipetting (VVP) uses inline MEMS flow sensors to measure every aspirate and dispense in real time, ensuring uncompromising accuracy, reproducibility, and confidence in every run. VVP is available in 96, 24, 8, and f4iz channel configurations, giving you flexibility for both high-throughput and highly specialized liquid handling tasks. Standard Technology (ST) Pipetting, offered in 24, 96, and 384 uniform-volume channel tools, is built for speed and flexibility—delivering robust performance across a broad range of protocols without sacrificing precision.

Combined with on-the-fly tool swapping, scalable automation, and support for diverse applications—from NGS prep to cell-based assays—the Lynx platform accelerates discovery while maintaining the highest standards of data integrity. Whether you need high-volume throughput or low-volume precision, Lynx gives you the versatility to do it all on one platform.

Key Features / Benefits

- VVP (96, 24, 8, f4iz) – Real-time volumetric verification for every channel

- ST (24, 96, 384) – Fast, robust, uniform-volume pipetting

- On-the-fly tool swaps – Change heads in <1 minute, no recalibration

- Five platform sizes – LM1800, LM1200, LM900, LM730i, LM700

- Linear-motor precision – Smooth, fast, repeatable motion

- Scalable integration – Works with incubators, conveyors, vision systems, and more

Applications

- High-throughput plate normalization, serial dilutions, and combinatorial pipetting

- Nucleic acid extraction & purification (e.g., SPE, magnetic-bead workflows)

- Sample distribution, media exchange, and cell maintenance in cell-based assays

- Liquid biopsy, large-volume extractions, and automated cleanup workflows

- Genomics (NGS, Sanger), transcriptomics, diagnostics, single-cell sample prep

- Automated library prep, compound screening, assay miniaturization, microarray processing