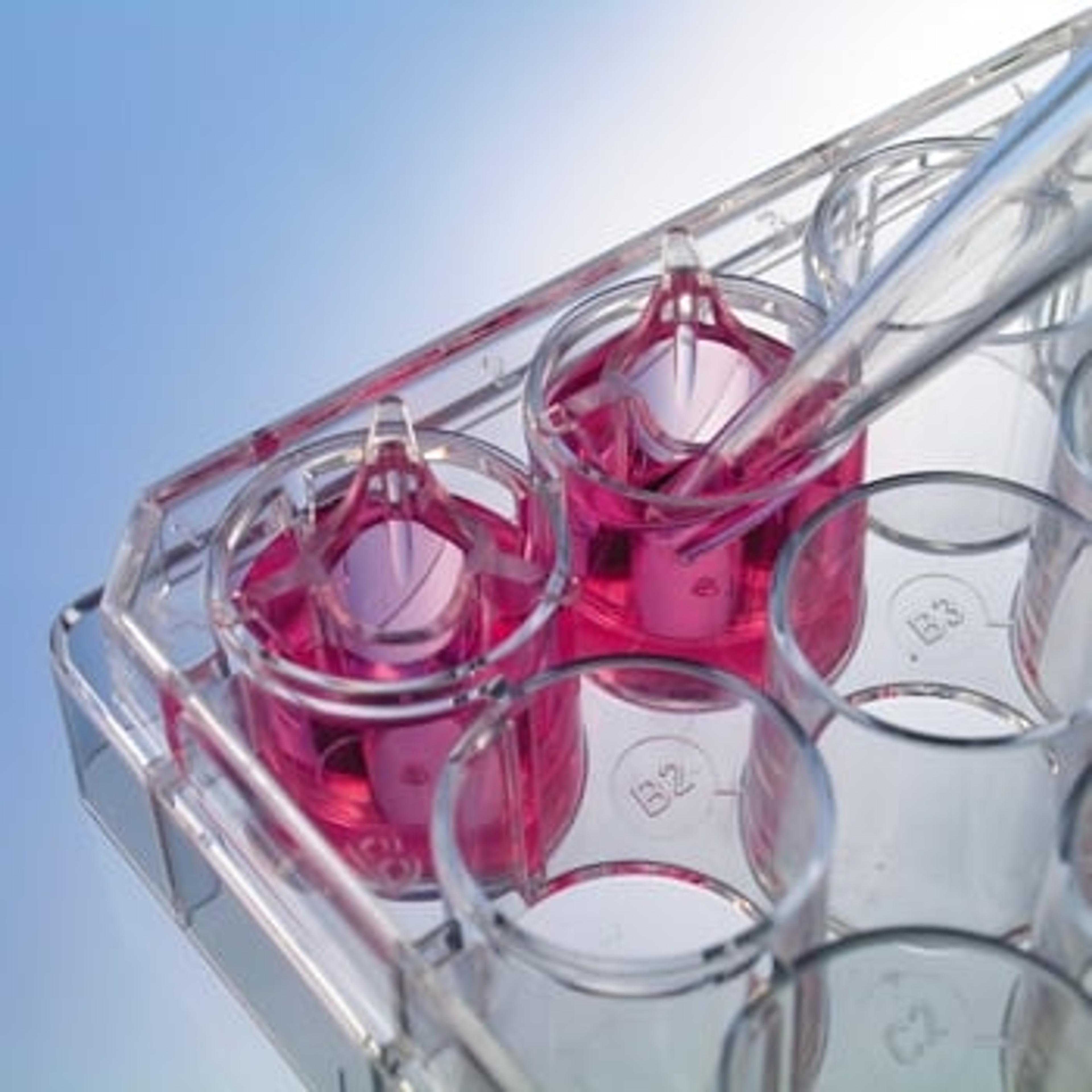

Driving drug discovery with enhanced cell culture capabilities

Philipp Wachter discusses the potential for innovative cell culture membrane inserts to supercharge drug discovery efforts

17 Sept 2024

Nine out of ten drug candidates fail during clinical trials. For companies working in drug discovery, this persistent high failure rate represents an enormous logistical and economic burden. Around $60 billion is spent each year on unsuccessful cancer drugs alone1. Strategic decisions must be made to select the optimum candidates for clinical development during preclinical evaluation. Two key approaches can be used to empower these decisions: (1) optimizing high-throughput screening (HTS) for example via innovative assay design and the replication of in vivo conditions for cell-based assays to enhance the predictive power of the screening outcomes, and (2) designing absorption, distribution, metabolism, and excretion (ADME) studies to provide a more comprehensive understanding of how drugs interact with the body.

ADME studies are essential for evaluating the safety and efficacy of drug candidates and making informed decisions about the further development. For example, a thorough understanding of drug absorption can help researchers design formulations that enhance bioavailability, and knowledge of a drug’s excretion profile can help determine a dose that avoids toxic accumulation.

ADME studies, alongside drug metabolism and pharmacokinetic (DMPK) studies, are also required by regulatory agencies, meaning that sound data can improve the chances of clinical trial approval for suitable agents. High-throughput products can drive success in ADME/DMPK studies by facilitating the rapid acquisition of accurate results while avoiding the consequences of methodological shortcomings.

Philipp Wachter is a Product Manager at Greiner Bio-One in Germany. He oversees the development of HTS products for drug discovery and development, as well as microplates for basic and diagnostic research. “Leading product performance is paramount to achieving experimental robustness and producing trustworthy data,” Wachter explains. “In particular, the critical role of high-performance products in ADME/DMPK studies cannot be emphasized enough. Product failure can produce misleading data and compromise essential qualities of the drug, such as efficacy and safety. Deceptive data can allow flawed drugs to move into the costly later stages of clinical development.

Innovations in cell culture technology enhance high-throughput screening studies

“The well-established ThinCert®product family – comprising a range of single membrane-based cell culture inserts for advanced cell and tissue culture applications – is an integral part of the Greiner Bio-One portfolio that can support different applications applied in ADME,” Wachter says. Among these applications are drug transport and permeability studies that focus on understanding how drugs move across biological barriers, such as cell membranes or tissue layers, within the body. These studies are crucial for evaluating the absorption, distribution, and elimination of drugs, as well as predicting their overall pharmacokinetic behaviour. Moreover, ThinCert® products can be used to generate air-liquid interface (ALI) cell cultures, which offer the capability to create robust and functional 3D in vitro airway cell models, replicating the characteristics of respiratory tract epithelia. Further applications include cell migration and invasion assays, which enhance our understanding of pathological and physiological events like tissue repair, inflammation, and tumorigenesis.

The newest addition to the ThinCert® family is one that Wachter is particularly excited about. This provides a high-throughput solution in addition to the established single-insert solutions. “We recently introduced the 96 well HTS inserts to the line,” he explains. “Each 96 well insert consists of a membrane and a respective receiver plate that creates in vivo-like cultivation conditions able to facilitate optimal cell growth, monolayer formation, and tissue differentiation. The automation-friendly ThinCert® 96 well HTS insert is also available in various membrane configurations that vary in size and density to cater to specific experimental requirements, including two 0.4 µm versions specifically designed for drug permeability and transport studies.

Miniaturize, automize, capitalize

Users of the ThinCert® 96 well HTS insert can also exploit its capacity for assay miniaturization. “The miniaturization approach enabled by the ThinCert® 96 well HTS insert affords several clear advantages and can be game-changing in ADME settings,” Wachter says. “Of note, it facilitates a more streamlined experimental process by allowing researchers to conduct multiple assays in parallel. This possibility makes experiments faster, saving time in the lab and expediting the drug discovery process while cutting costs for companies. In the resource-intensive drug development landscape, these cost savings could make a real difference.

The 96-well HTS inserts also allow researchers to use reduced sample volumes while maintaining assay sensitivity. The ability to use smaller volumes can be particularly advantageous when dealing with substances or cells that are considered precious or have limited availability.

The ThinCert® 96 well HTS insert also has a newly developed membrane configuration with high transparency and a dense pore structure, which addresses existing limitations in cell monitoring. “Enhanced membrane transparency was prioritized in response to user feedback,” Wachter explains. “We engaged extensively with end-users during plate development and collaborated closely with experienced researchers to address any concerns and eliminate existing limitations. Many users requested improved membrane transparency. However, achieving high diffusion rates and optimal conditions necessary for permeability and transport studies demands a dense pore structure, consequently resulting in a translucent membrane. We focused on optimizing the membrane configuration and developed a version that retains a high pore density while providing improved imaging quality for live cell observations."

A view to tomorrow

Looking ahead, Wachter and his team at Greiner Bio-One hope to continue optimizing the processes central to their customers’ cell and tissue culture research. Doing so will allow them to continue to make valuable contributions to the development of new drugs to fight diseases like cancer. “We have lots of experience in manufacturing products for cell culture applications – this is a key area where we strive to make a meaningful impact,” Wachter says. “We are committed to developing our products to meet our customer’s requirements and always keep the final application in mind when doing so.”

Wachter also explains that he does not see Greiner Bio-One as a manufacturer that produces simple plastic labware.. He says, “We combine state-of-the-art injection molding with advanced surface modification technologies to produce sophisticated, and sometimes even customized, chemical and biological coated products that meet the specific needs of cultivating complex cell models both in 2D and 3D.

ADME/DMPK studies can be incredibly complex, but companies such as Greiner Bio-One are working hard to streamline the involved processes to help drug developers get effective treatments to the patients who need them.

Reference

Mullard A., et al., The high, and redundant, cost of failure in cancer drug development. Nat Rev Drug Discov (2023).

Learn more about Greiner Bio-One >>