Streamline biologics development with automated cell incubation

Learn how Thermo Fisher Scientific’s Cytomat™ 2 Selector Automated Shaking Incubator can enable biologics to reach the market faster

6 May 2024

Manual processes in the biologics workflow pose many challenges for drug developers, which can prevent these important drugs from getting to market quickly. To expedite the journey of these potentially life-saving treatments to patients, innovative automated technologies are helping scientists navigate the complex biologics development process with greater speed and efficiency.

Dieter Wagner, Cytomat Product Manager at Thermo Fisher Scientific, discusses a new, cutting-edge automated cell shaker and incubator that can help streamline the biologics workflow and shorten time to market. Wagner provides an overview of some of the most important stages in the development of biologics, explains how automation can help tackle common challenges, and discusses the benefits of the Thermo Fisher Scientific Cytomat™ 2 Selector Automated Shaking Incubator.

Biologics allow for more tailored and effective treatments

The landscape of drug discovery is undergoing a significant transformation, transitioning from traditional small molecules to biologics, which are larger and offer several advantages over their smaller counterparts. In 2022, 40% of the FDA-approved drugs were biologics1, highlighting the importance of these drugs in the medical industry.

Biologics are produced using living organisms and encompass therapeutic agents such as monoclonal antibodies (mAbs), vaccines, and cell and gene therapies. One key benefit of biologics is their precision targeting capabilities, allowing for more tailored and effective treatment options. They also generally exhibit fewer contraindications and reduced potential for drug interactions, enhancing patient safety. What’s more, biologics tend to have a higher success rate and can yield a more favorable return on investment (ROI) due to shorter development times.

Cell line development within the biologics workflow

Cell line development is a crucial stage in the biologics development workflow. This complex and iterative process aims to generate stable and well-characterized cell lines that produce specific proteins, antibodies, enzymes, or other biologics of interest, for various applications including recombinant protein production, drug discovery, and biomanufacturing. Wagner explains: “The first step in the cell line development workflow is transfection, involving the introduction of nucleic acids, either DNA or RNA, into cells. The outcome of this introduction can vary: the nucleic acid sequence may either exist transiently within the cell or be stably integrated into the host cell's genome. Cells transiently transfected only express the protein of interest for a limited time, allowing for efficient screening of a large number of proteins.”

“After transfection, clone selection takes place in which a single superior clone is identified from genetically identical cells. High-yield clones then undergo small volume scale-up, amplifying cell numbers while maintaining quality,” Wagner continues. “Following this step is formulation development which involves crafting the optimal composition and conditions to ensure stability, efficacy, and appropriate delivery of the therapeutic protein. Lastly, production is scaled up gradually, accompanied by stringent quality assurance measures.”

Automation overcomes cell growth limitations

Shaking incubators are an essential piece of laboratory equipment for biologics cell line development. They are used to cultivate and grow cell lines under controlled conditions, ensuring optimal growth, protein expression, and other desirable characteristics. Their ability to evenly distribute nutrients, oxygen, and waste products ensures consistent healthy cell growth and reproducible outcomes. However, a key obstacle for the biologics industry has been the reliance on non-automated shaking incubators with limited shaking capacity. These lack programmable controls and require manual adjustments for temperature, agitation speed, and other parameters.

Wagner says: “The three main pain points for drug developers are increasing throughput, minimizing variability, and improving workflow efficiency. The only way to address these challenges is by automating biologics workflows on a larger volume scale. Automation offers several advantages, including enhanced accuracy, reproducibility, and increased throughput. By minimizing human intervention, the potential for errors and variability is significantly reduced. The market is in need of an automated shaking incubator that can shake large volumes in Society for Laboratory Automation and Screening (SLAS (SBS)) vessels or large deep-well plates, is consistent across all positions within the incubator's stacker, and ensures reliable reproducibility of results.”

Wagner explains that during transient transfection, the primary labware used is 96-deep well plates to achieve a volume of 3.5 ml with a protein concentration of 1.000 mg/L. In the clone selection phase, the desired volume increases to around 30 ml. “Currently, the automated workflow involves using a 3 mm shaking diameter, but achieving the 30 ml target volume requires the cell line to be divided among multiple wells or plates. On the other hand, the manual process step utilizes an offline incubation shaker with a larger 25 mm shaking diameter, allowing the use of different labware, particularly SLAS (SBS) labware. To automate this manual step, an automated shaking incubator with the same 25 mm shaking diameter and comparable incubation performance is needed.”

Enhance cell line development with the Cytomat™ 2 Selector Automated Shaking Incubator

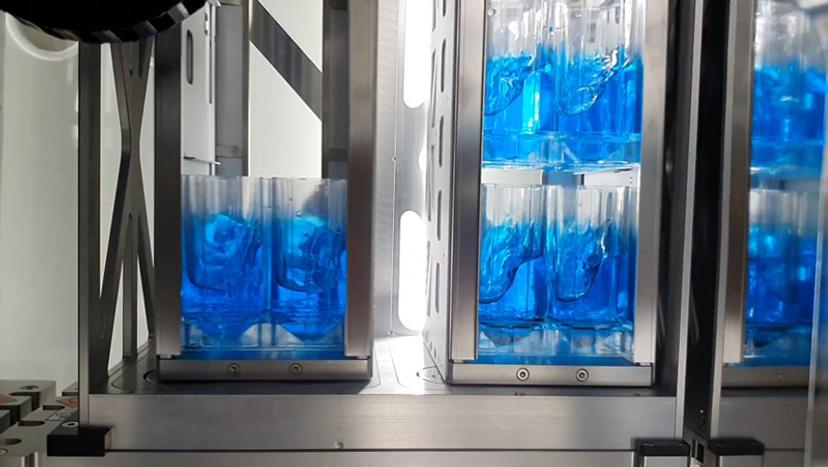

The Thermo Scientific™ Cytomat™ 2 Selector Automated Shaking Incubator is the first automated incubator for biologics with large amplitude shaking and is designed to overcome current cell growth limitations from low volume form factor to culture vessels (SLAS (SBS)-Format). It enables manual biologics shaking processes to be simply copied and offers a 25 mm shaking diameter and biologically relevant speeds (100-350 rpm).

As the newest incubator in the Cytomat 2 C-LiN Series, the Cytomat 2 Selector Incubator comes with the same state-of-the-art features as the classic Cytomat 2 C-LiN Series, providing optimal conditions for cell growth through consistent maintenance of stable temperature, relative humidity, CO2 levels, and efficient decontamination.

“The Cytomat 2 Selector matches the shaking and incubation performance of manual incubators available on the market. Thanks to its plate shuttle system it works with SLAS-footprinted labware, for example, 24-deep well or 6-deep well plates with 30 ml capacity per well. The Cytomat 2 Selector streamlines the transition from manual to automated processes, enhancing efficiency and throughput in clone selection and transient transfection scale-up. It also ensures consistent and reproducible results,” Wagner comments.

Equipped with two synchronized shaking drive systems positioned at the top and bottom of each stack, the Cytomat 2 Selector offers uniform shaking across all plates, regardless of their position or load. These two shaking stacks can run different applications concurrently, boosting flexibility. This design also enables unloading from one stack while the other continues shaking, enhancing process stability. “The incubator features an active plate clamping mechanism that secures plates for consistent results. Additionally, it includes a standard automated decontamination routine named ContraCon, which ensures safe and effective cleaning between runs without the need to remove hardware, significantly minimizing the risk of contamination,” adds Wagner.

Upgrade your biologics workflow with the Cytomat 2 Selector

The Cytomat 2 Selector is currently available with four different shaking modules that can be chosen individually. These modules are designed for labware with heights of either 47 mm (Pitch 52) or 90 mm (Pitch 95) for sealed plates, as well as two additional modules for labware with heights of 52 mm (Pitch 57) or 95 mm (Pitch 115) for plates with lids. Wagner strongly recommends using the new robot-friendly covers available, which were developed in collaboration with the plate and lid manufacturer, Enzyscreen, BV, specifically for the Cytomat 2 Selector. Adding to its versatility, the Cytomat 2 Selector boasts a remarkable maximum payload capacity of 2,200 grams per stacker. This capacity empowers researchers to tailor their experimental setup according to the requirements of various applications within the transient transfection and clone selection workflow.

The introduction of innovative automated shaking incubators offers a game-changing solution to the challenges faced in biologics development. By automating key processes and providing the necessary flexibility, state-of-the-art incubators such as the Cytomat 2 Selector empower researchers to enhance efficiency, maximize throughput, and ensure consistent, reproducible results, ultimately accelerating the journey of biologics to market and improving patient access to life-saving treatments.

References

Martins A.C, Albericio F, de la Torre B.G, FDA Approvals of Biologics in 2022. Biomedicines, (2023) May;11(5):1434. Pubmed