Recombinant protein advancements revolutionize assay development

Toni Ertl shares how The Native Antigen Company’s new human health recombinant proteins are advancing assay development in diagnostics and vaccine research

27 Oct 2025

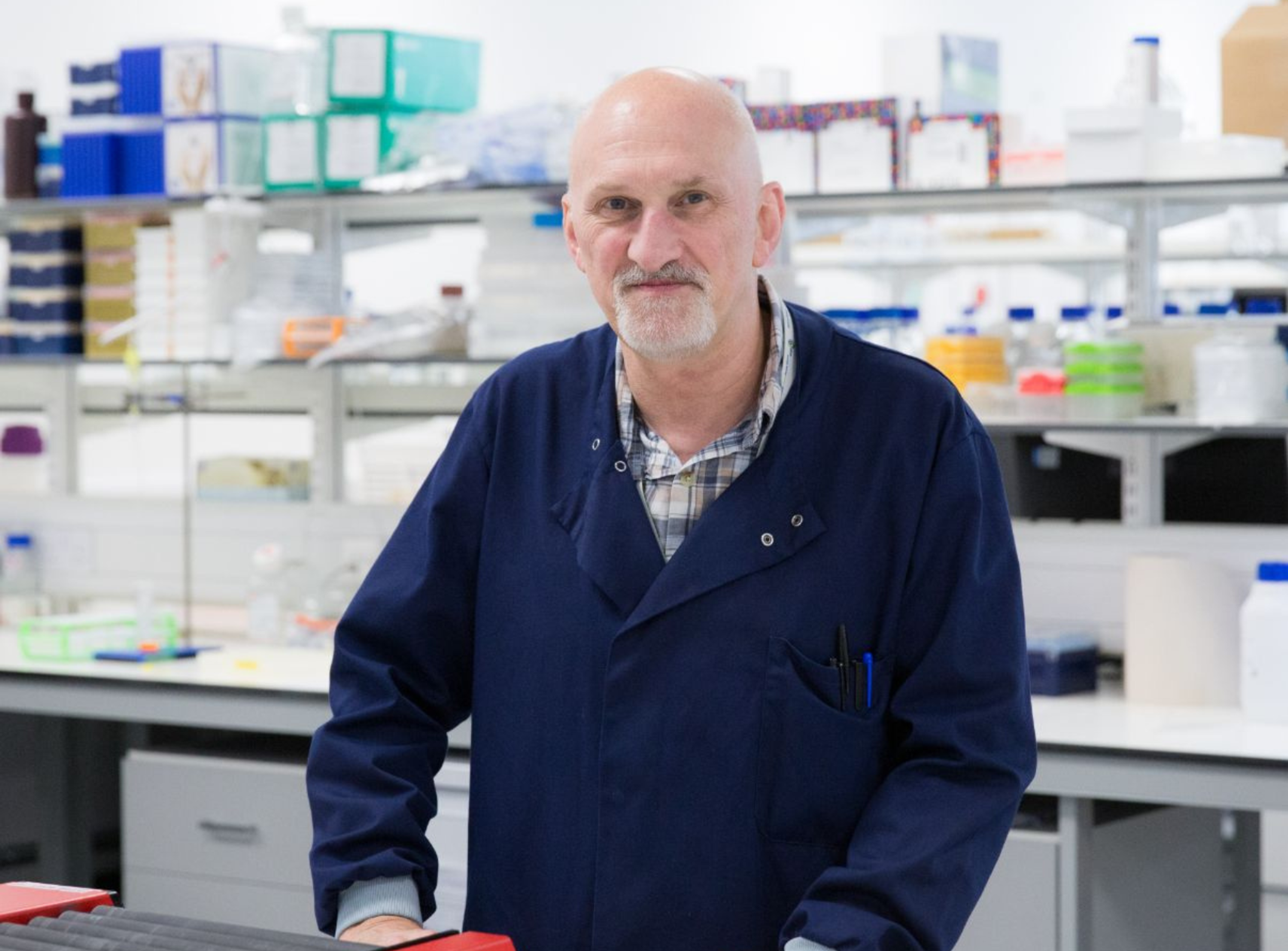

Toni Ertl, Senior Scientist at The Native Antigen Company

Since its establishment in 2010, The Native Antigen Company (part of the LGC Group) has grown rapidly, becoming one of the world’s leading suppliers of infectious disease reagents. The company’s mission, to reduce the global burden of infectious disease by developing the highest-quality disease reagents possible, is a noble one – backed up by a strong developmental team. Toni Ertl, Senior Scientist at The Native Antigen Company, shares what makes The Native Antigen Company unique and the exciting developments they are currently working on.

Expanding capabilities through strategic growth

Over the last 15 years The Native Antigen Company has grown strategically, ensuring it can remain agile whilst developing reagents for large scale processes. “We’ve gone from being a company producing niche reagents for a small customer base to developing products that support high-impact, large-scale diagnostic platforms,” comments Ertl. “We’re very excited because these new recombinant proteins open the door to supporting much broader diagnostic and vaccine development applications.”

The Native Antigen Company recently joined the LGC group, an exciting development which has only enhanced its production capabilities while sticking to its founding ethos. As Toni explains, “although we’ve been around about 15 years, we’re still very entrepreneurial. Some of the founders are still here. Even though we’re now part of LGC, we remember our roots.”

The company's work is focused on ensuring it delivers products that will be indispensable to customers. “A large part of what we do is figuring out how what we make will be used by our customers,” Toni explains. “Assessing parameters such as stability, aggregation, and reactivity to provide assurance that our reagents will support the work they're doing. We tailor our Certificate of Analysis based on what it is the customer is likely to want to know (purity, concentration, activity, buffer formulation) and also sometimes physical characterization using more application-specific performance data like FFF-MALS where relevant.”

Innovating with recombinant technologies

While a significant proportion of the company’s work is focused on custom services for institutions such as the University of Oxford, the team is also working on a number of innovative projects, forecasting emerging and recombinant technologies to stay ahead of the curve. “Over the last 10 years, we’ve moved from hybridoma-based monoclonal production to recombinant antibody technology. Now we’re seeing antibody engineering go even further, not just swapping variable domains, but tuning affinity, binding speed, and release kinetics,” comments Ertl.

One exciting area of innovation is the development of a recombinant rheumatoid factor. Rheumatoid factor is a critical biomarker in the diagnosis and management of autoimmune diseases, particularly rheumatoid arthritis; it is also an essential quality control material for automated immunoassay analyzers. “About 18 months ago, we started a program to try and make a recombinant rheumatoid factor and developed a range of cell lines that secreted humanized IgMs with rheumatoid factor-like activity,” shares Ertl.

The development of this recombinant factor is exciting because human derived sera has long served as the primary source of rheumatoid factor in clinical laboratories. “We are finding that the human sera rheumatoid factors are increasingly hard to source, but still essential for assay controls and immunodiagnostic development,” Ertl explains. “However, due to the development of better therapies we are seeing fewer people with high levels of rheumatoid factor, but we do still need it for use in controls for automated analyzers.”

Standardizing assays for global impact

The move to recombinant rheumatoid factor use is also about more than just supply. It is about standardization and reproducibility, with natural rheumatoid factors from serum varying greatly between different donors or batches. Excitingly, recombinant rheumatoid factor provides the consistency needed for regulatory submissions, clinical assay development, and internal quality control programs. “It’s very important that customers can be confident our products will work the way we claim they will,” says Ertl. “With a recombinant rheumatoid factor, we can ensure stability, behavior, and concentration that meet their specifications.”

What originally began as a small-scale project, has now grown into a full-scale project with imminent commercialization in the pipeline. “In the next couple of weeks, we're going through our first bioreactor growth run,” Ertl shares. “That will allow us to scale to match all our forecasted needs in the future.”

Looking to the future

This project encapsulates the company’s broader push into recombinant antibody production, cancer markers, and hormone targets. With access to advanced technologies becoming easier, the landscape of antibody production is continuing to evolve. “I expect AI to play a major role in the design of antibody variable domains, helping tailor antibody characteristics from the ground up for specific applications.”

With the launch of its recombinant factor product, the company is poised to make an immediate and measurable impact on the diagnostics immunology sectors, a development which certainly will not be the last from this group. Ertl concludes, “it's exciting to see how we have gone from being a couple of people in a shared laboratory through to having a really good facility, and being part of a much larger organization. We continue to do things that we feel are making people's lives better. And for us, making a difference is what is really important.”