Overcoming challenges in lateral flow test development

Lateral flow test development experts share troubleshooting tips and discuss how Merck’s Hi-Flow Plus membranes can streamline assay development

28 Jul 2025

Perhaps best known for their widespread use during the COVID-19 pandemic – and as the core technology behind pregnancy tests – lateral flow tests (LFTs) have emerged as a mainstay of modern healthcare. Hailed for their speed, simplicity, and suitability for both point-of-care and at-home settings, LFTs are now being explored for a growing range of applications, from multiplexed clinical diagnostics to environmental monitoring.

Jackie Day is Senior Commercial Project Manager for Assay Development Services in the Americas. Peter Curley is a Principal Scientist based at Merck’s membrane manufacturing facility in Cork, Ireland.

Despite their versatility, developing a reliable LFT is anything but straightforward. Challenges such as inconsistent performance, low sensitivity, and high background noise can derail even the most promising assays. Merck’s LFT experts, Jackie Day and Peter Curley, share actionable strategies for overcoming these hurdles. They also explain how Merck’s Hi-Flow Plus membrane, designed for optimal capillary flow and minimal background noise, can enhance assay sensitivity, reproducibility, and overall performance.

Simple to use, less so to develop

At first glance, a lateral flow test appears deceptively simple. It is compact, has no moving parts, and consists of just a few visible components. Yet beneath that simplicity lies a finely tuned system of immunochemistry, nanomaterials, and membrane engineering.

“Lateral flow tests are simple to use, but not simple to develop,” explains Day. “And because there are so few components, each one plays a critical role in the overall performance of the assay.”

The most common challenges encountered during LFT development – and the defects most frequently reported by end users – are low sensitivity, false negatives, false positives, high background noise, and irregular or slow sample flow. Each of these issues can stem from a wide range of causes, including problems in biological reagents, chemical formulations, physical strip construction, or the materials and processes used during assembly.

Focusing first on the biological and chemical aspects, Curley emphasizes the importance of using high-quality reagents, particularly highly pure, lot-to-lot consistent antibodies. He also stresses the need to tightly control buffer compositions, especially considering the effects of water evaporation during manufacturing. “Since you’re drying aqueous reagents onto porous membranes, solute concentrations can increase as water evaporates, and too much solute can denature critical components like antibodies,” he explains. “There’s a lot to consider to ensure reagents dry in place, remain stable during storage, and rapidly rehydrate and become biochemically active when the sample arrives.”

Physical hurdles can involve issues with sample flow, which can be influenced by strip construction and housing design, pad and membrane material properties, or the nature of the sample itself. “If you’re working with viscous samples like saliva or serum, or if your materials aren’t aligned properly, flow can become inconsistent,” Curley explains. “The material bed volume (the volume of liquid each material can absorb) is dependent on its porosity, thickness, and dimensions, each contributing to overall absorptive capacity, retention, and efficiency of sample release. The total bed volume and composition will determine the amount of sample that can be loaded onto the test, how it flows, and in turn, how much analyte reaches the test line and how strong your signal will be.”

Materials and assembly processes also play a crucial role, with the membrane typically receiving the most scrutiny as it affects a sample’s capillary flow time and is where the assay capture zone is located. “When issues arise, the immediate reaction is usually, ‘It must be the membrane’,” says Day. “In the vast majority of cases, the challenge isn’t the membrane itself, but something else in the system — like the antibodies, detector particles, layout, or a small detail in the production process.” In relation to challenges associated with assembly, we advise conducting a visual inspection of the test strips during the assembly process, as detecting errors early is crucial to minimize the waste of valuable materials.

How to troubleshoot a lateral flow test

With so many potential causes behind lateral flow test issues, pinpointing the root cause can be daunting. According to Day and Curley, the key lies in adopting a holistic yet systematic approach.

1. Start with the basics: Raw materials and equipment

First, check that all raw materials conform to their specifications. This includes biological reagents like antibodies and blocking agents, as well as chemicals and membranes. Are there any potential issues with lot-to-lot variability? Has everything been stored and handled properly before the manufacturing process? Any deviation here can compromise assay performance.

Next, evaluate manufacturing equipment and processes. Was all equipment operated within validated process parameters, and were calibration and maintenance protocols followed? Here, attention to detail is essential, for example, ensuring proper calibration of pipettes and balances, as well as the cleanliness of solution preparation vessels.

“If your assay was working and now it’s not, ask yourself: What changed?” says Day. “It might not be the materials at all — sometimes packaging, manufacturing conditions, or equipment calibration can be the culprit.”

2. Revisit the assay design

From a development standpoint, revisiting the assay design is crucial when performance issues arise. “If an assay isn’t performing as expected the first thing I do is go back to the design,” Curley says. “Was the correct assay format chosen? Were the right antibodies, detector particles, and membrane selected during the feasibility phase?”

He also highlights the need to carefully assess the conjugation process: “Is the right amount of antibody coated on the particles, and are the binding conditions optimal? If there’s non-specific binding on the membrane, it may be necessary to revisit both particle and buffer blocking strategies and/or reduce the amount of capture antibody at the test line.”

Strip design details matter too. “Is the strip designed properly? Are the overlaps aligned to ensure that most of the sample reaches the test line and reacts with the reagents?” Curley adds. “Those are the kinds of questions we constantly ask.”

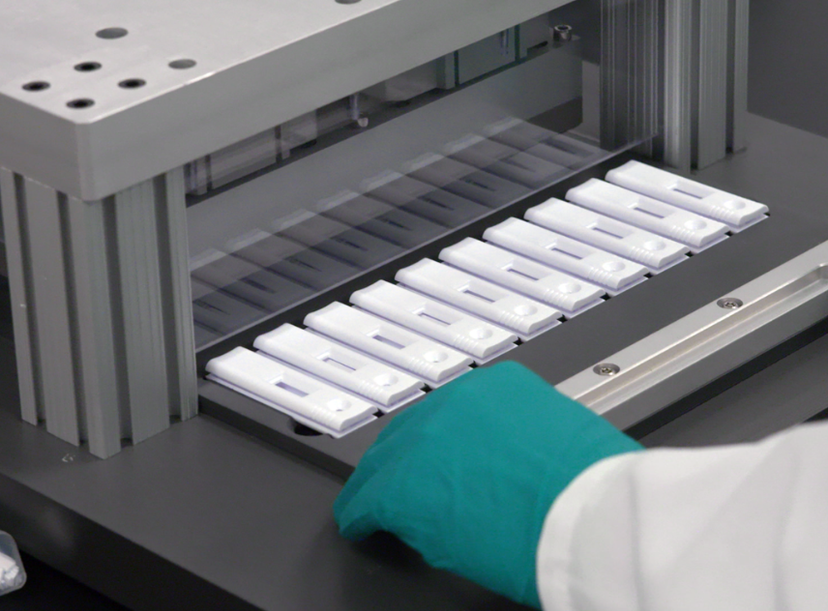

3. Use a half-stick assay

One way to speed up troubleshooting is to use a half-stick assay. Instead of working with a full strip, this method simplifies the test to just the membrane and absorbent pad. The other components, like detector particles, sample buffer, and the sample matrix are maintained in a liquid state in a 96-well plate.

This reduction in complexity makes it easier to pinpoint issues related to membrane chemistry and flow without interference from other variables such as housings or sample pads.

Once the membrane and reagents are confirmed to be working well, complexity can be added back stepwise, introducing the conjugate pad, sample pad, and eventually the full test strip. This stepwise approach avoids unnecessary troubleshooting of components that are not problematic.

Streamline assay development with the right materials

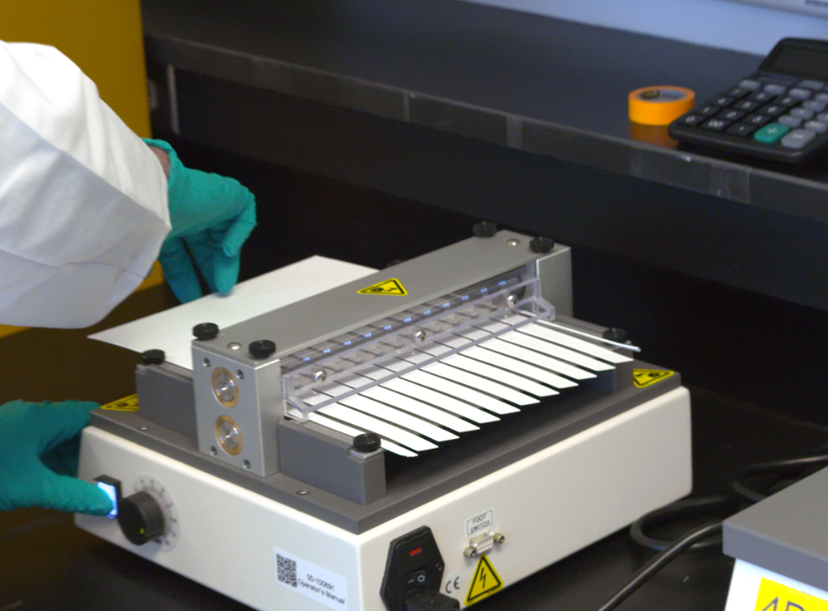

Hi-Flow™ Plus membranes offer five flow rates to suit various sensitivity needs and are available in sample sheets, slit rolls, bulk master rolls slit to custom widths, and preassembled membrane cards.

When developing any assay, high performance begins with high-quality materials — and cutting corners here can derail even the most carefully designed tests. “Garbage in equals garbage out,” says Day. “If you’re not starting with the best-quality materials, you’re not going to get the best-quality assay. Whether you’re aiming for sensitivity, selectivity, or speed, a lot of that hinges on choosing the right components.”

One of the most critical components in a lateral flow test is the membrane. It directly influences capillary flow, reagent deposition, test line clarity, and ultimately, assay sensitivity. “The membrane is often the rate-limiting step in a lateral flow assay,” Curley explains. “Membranes differ in flow rate and protein-binding capacity. If high sensitivity is required, a slower-flowing membrane allows more time for binding. If speed is the priority and sample availability isn’t a concern, a faster membrane may be more appropriate. There’s a lot to consider when selecting the right membrane for your assay.”

To support these different needs, Merck offers Hi-Flow™ Plus membranes with five distinct flow rates, from fast (Hi-Flow™ Plus 75) for time-sensitive assays, to slow (Hi-Flow™ Plus 180) for tests where sensitivity or sample conservation is critical.

Beyond flow rate, Hi-Flow™ Plus membranes are designed with unique surface morphology that promotes even reagent distribution and minimizes background noise, helping developers achieve sharper test lines. And thanks to rigorous manufacturing controls, these membranes deliver trusted lot-to-lot uniformity. “Medical devices and IVDs need to perform the same way every single time,” says Day. “Customers have highlighted that consistency during scale-up is critical — with other membranes, they’ve seen scrap rates reach 25–30% due to variability.”

Curley recalls one such case, “A customer came to us after struggling with sensitivity, weak line intensity, and inconsistent test line width using a competitor’s membrane. We did a direct comparison, and the Hi-Flow membrane delivered significantly stronger line intensity and better sensitivity for their application. They ultimately made the switch, and it was a great success. It’s a perfect example of how better material selection can directly improve assay performance.”

Request a free sample pack of Hi-Flow™ Plus membranes to explore how they might improve your assay.

Being a raw material manufacturer also gives Merck a forward-looking edge. “We have insight into what’s coming,” Day says. “We’ve helped customers overcome tough issues by recommending detection protocols based on materials that hadn’t yet launched or weren’t widely known, simply because we knew they were coming.”

One such innovation is Merck’s high-intensity latex beads, which provide up to tenfold greater sensitivity than traditional gold nanoparticles while still being visually readable. “It’s a strong option for developers who want more sensitivity without adding the cost or complexity of fluorescent detection,” she adds.

And in a world where supply chain reliability can make or break a diagnostic product, Merck’s global scale offers additional reassurance. “It’s not just about having the right material, it’s whether you can keep using it,” Day emphasizes. “Will your vendor still have it during a global disruption? Will it meet the same standard six months or three years from now? If you’ve validated your assay on a material, losing access becomes a major problem.”

To help mitigate those risks, Merck is investing in long-term supply stability with a new membrane manufacturing facility in Sheboygan, Wisconsin, expected to boost production capacity by over 50%. “This will provide a local supply of IVD-grade material in the Americas,” Day notes, underscoring its importance amid current global trade uncertainties.

Ultimately, it is Merck’s focus on quality and support that rounds out its value to assay developers. “Our Hi-Flow membranes are designed, developed, manufactured, and packaged to the highest standards, with full traceability,” Day says. “That level of reliability is a huge value — and that’s not just my opinion; it’s what we consistently hear from our customers.”

Curley agrees, “It’s not just the materials, it’s the combination of technical support, regulatory insight, and our assay development services. That’s what truly sets us apart.”