How to Buy Liquid Handling Technology

27 Nov 2025

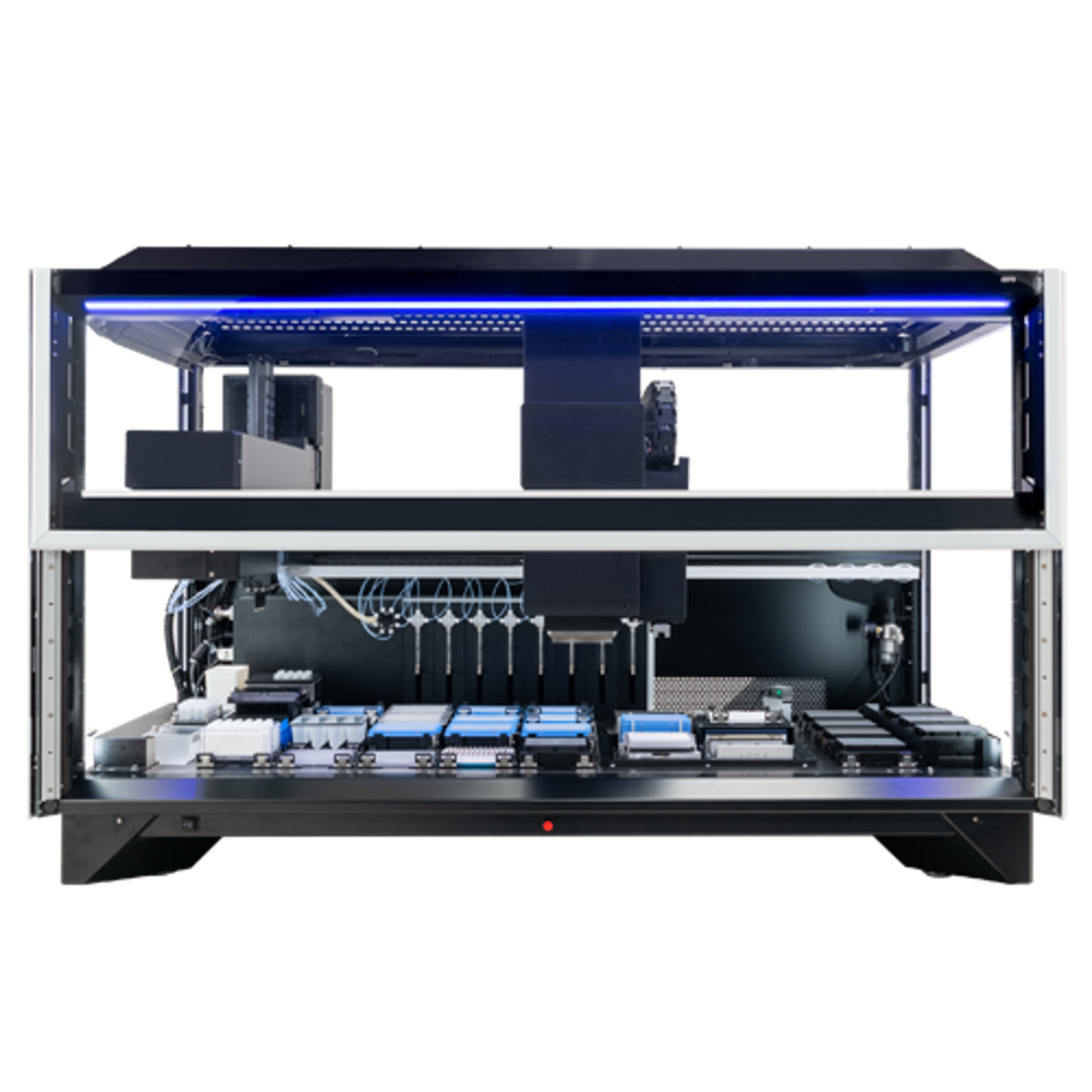

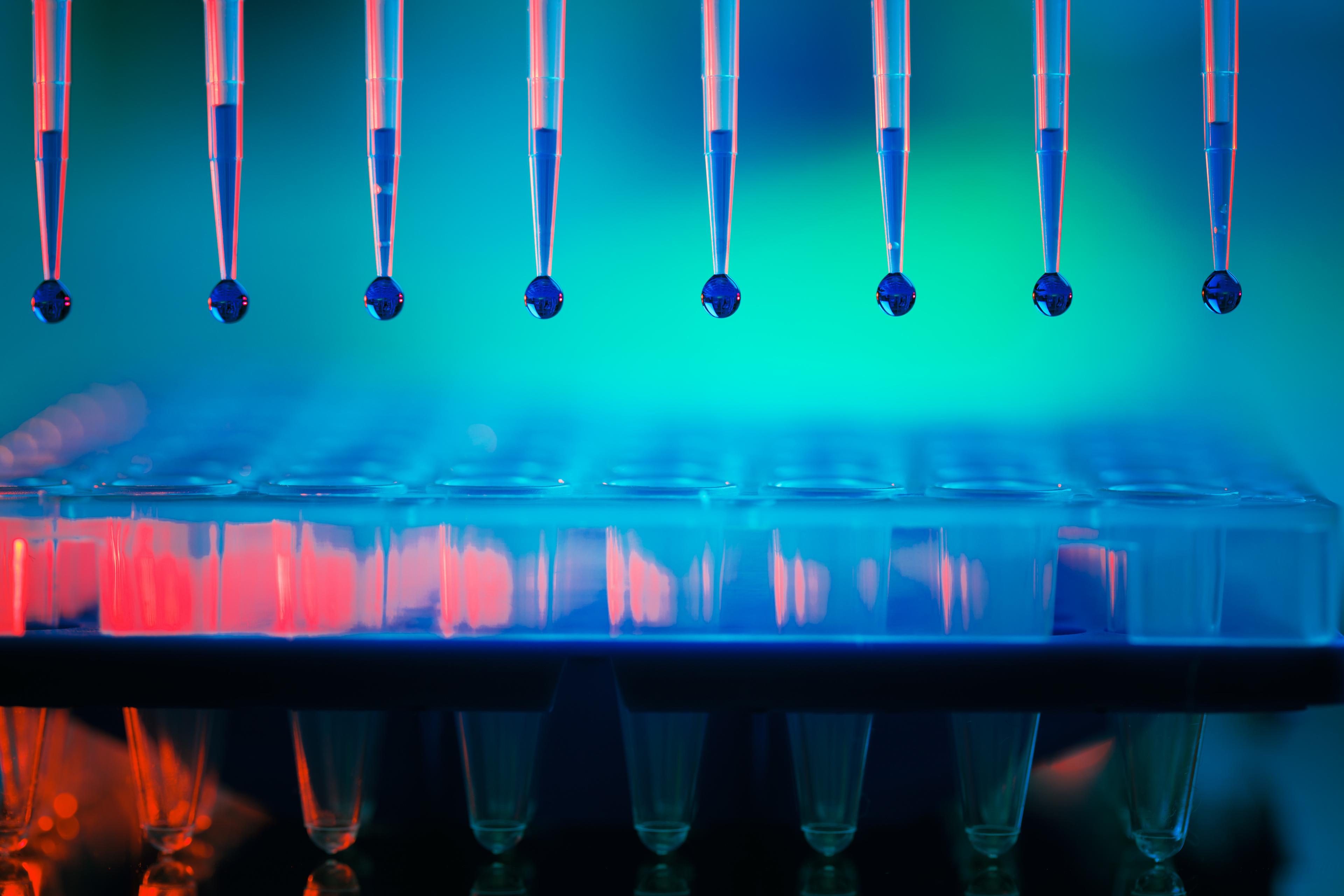

Liquid handling technology is a cornerstone of lab operations that encompasses a wide spectrum of tools, ranging from manual or electronic pipettes to sophisticated, room-sized multifunctional liquid handling robots. Choosing the right liquid handling solution is essential, as it not only directly impacts the accuracy and repeatability of experimental results, but also determines whether your lab can meet its throughput requirements.

How to choose the right liquid handling technology for your lab workflows and applications

In this 14th edition eBook, we present an expert guide to help you purchase the most suitable liquid handling technology for your work.

For labs in search of a liquid handling equipment, the decision-making process can be overwhelming due to the volume of options available. Available technologies range from manual pipetting techniques to sophisticated automated liquid handlers.

Download this buying guide to gain valuable insight into:

- Key pipetting technologies - manual vs electronic pipettes

- Automated liquid handling & robotic systems

- The importance of miniaturization & sustainability

- Top tips and key considerations from the experts

- The future of liquid handling and its application in NGS and beyond

Resource details:

- Document type: SelectScience guide

- Page count: 22

- Read time: 33 mins

- Edition: 14th