Application Notes

Resources

25

Application Notes

Chromapedia pocket guide

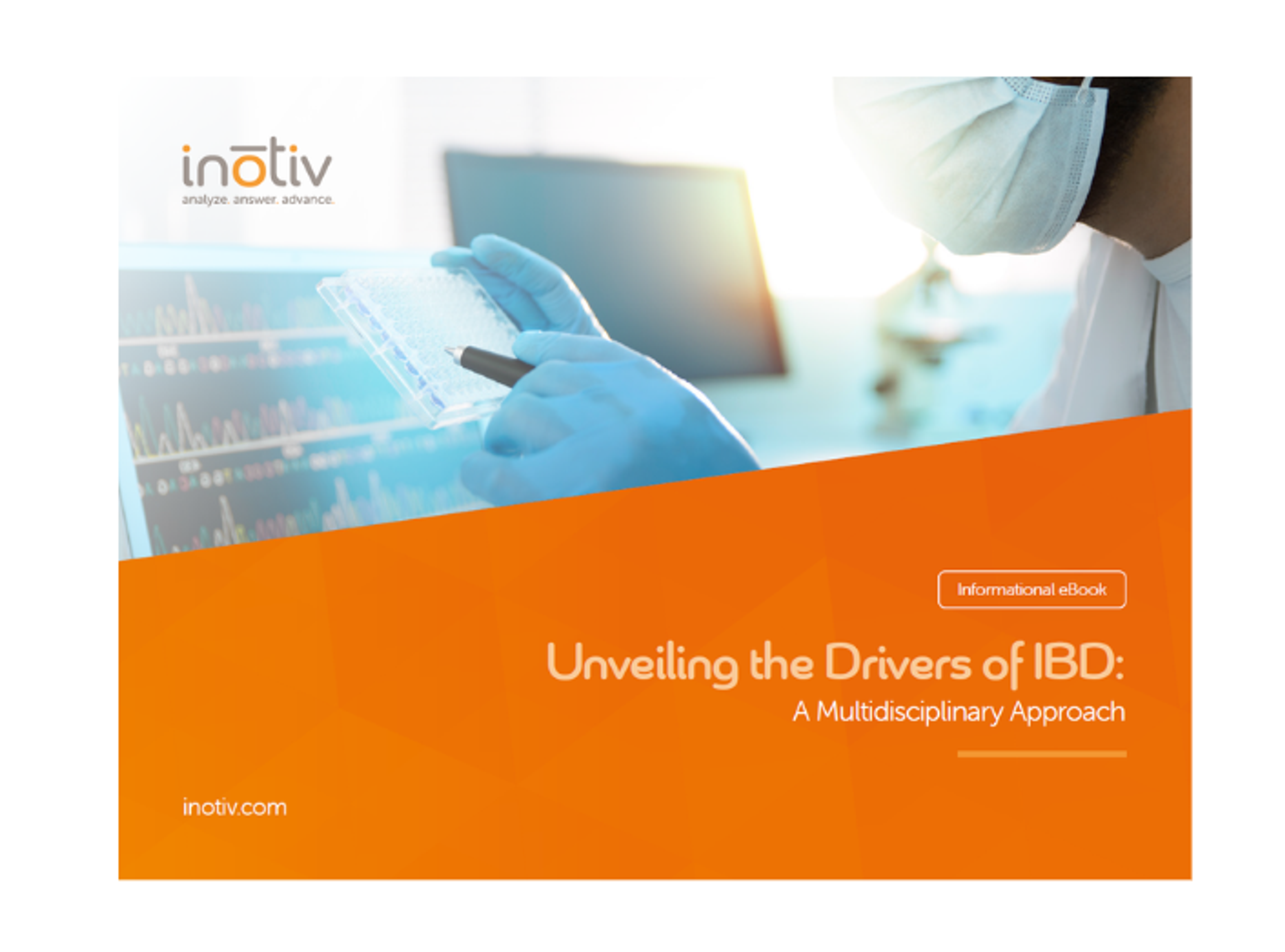

Application eBooks

Early cancer detection with multiplex immunoassays

Your guide to achieving sensitivity, specificity, and scalability with multiplexed biomarker analysis

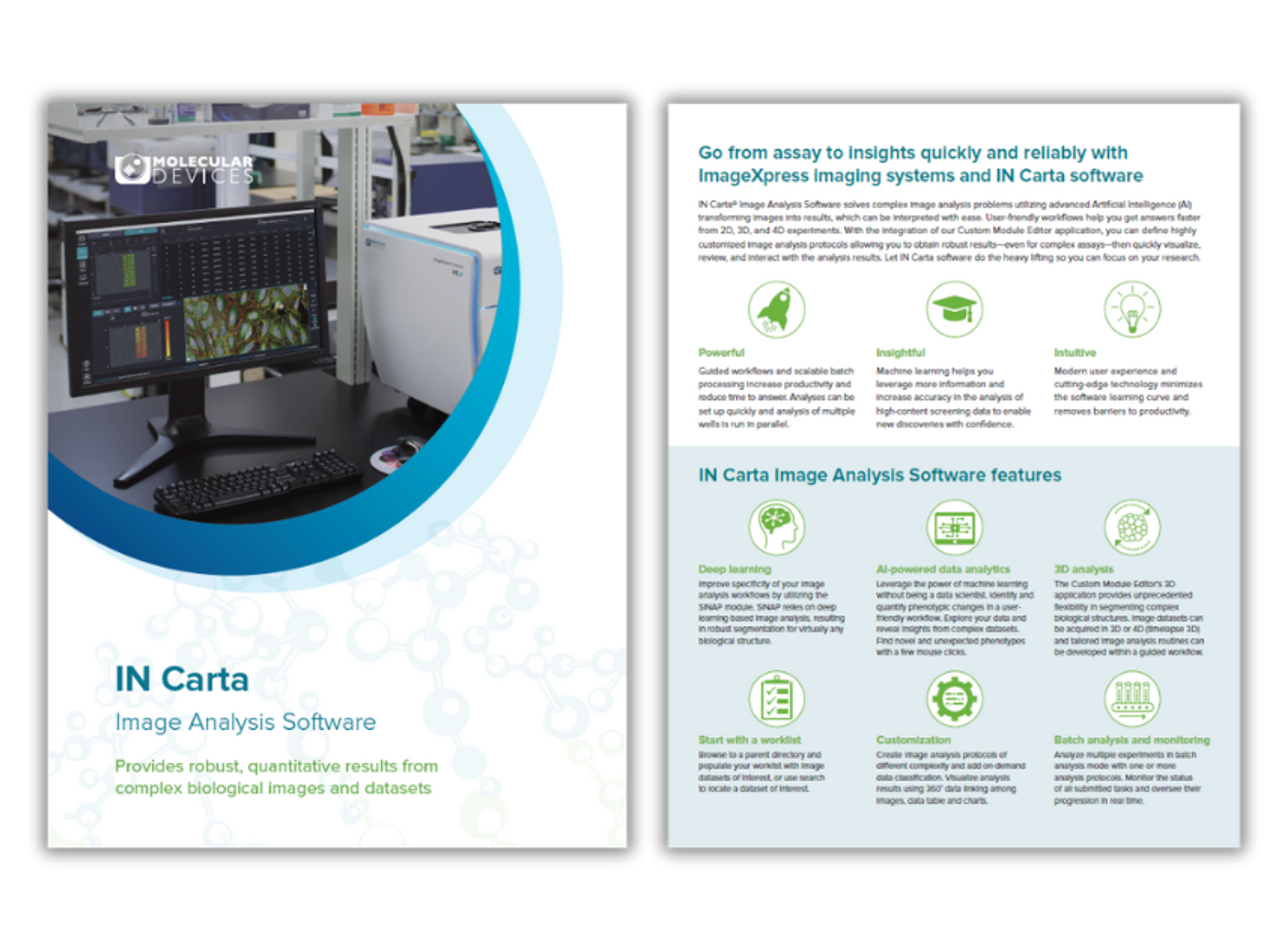

Product Brochures

IN CARTA Image Analysis Software

Product Brochures

ASSIST PLUS and ASSIST

Application Notes

Cellular imaging insights

Application Notes

High-throughput antibody production, from design to data

Application Notes

Choosing the right ITC binding experiment

Application Notes

A practical path to physiologically relevant cell models

Application Notes

Applications guide to food and beverages

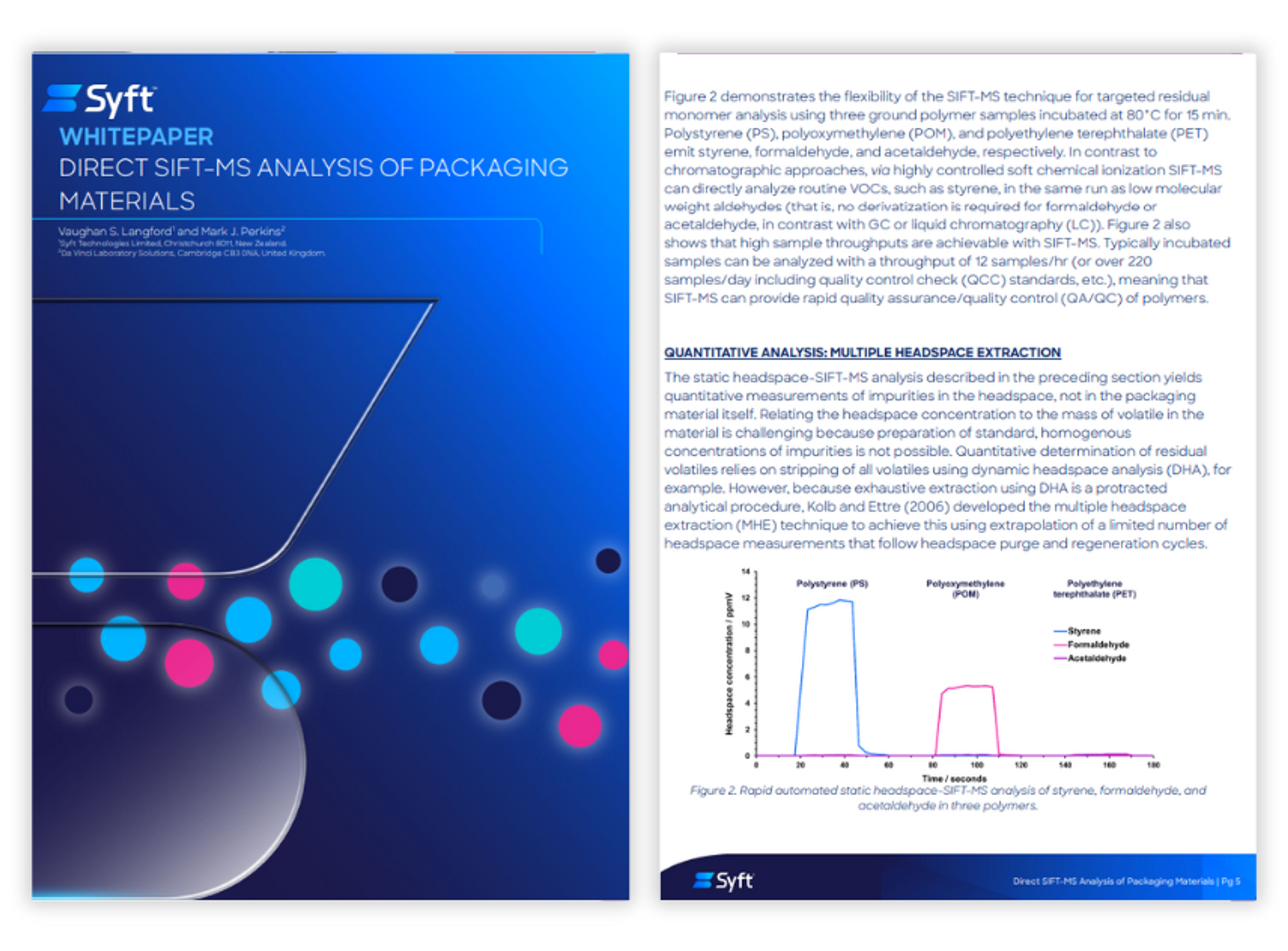

White Papers

Direct SFIT-MS analysis of packaging materials

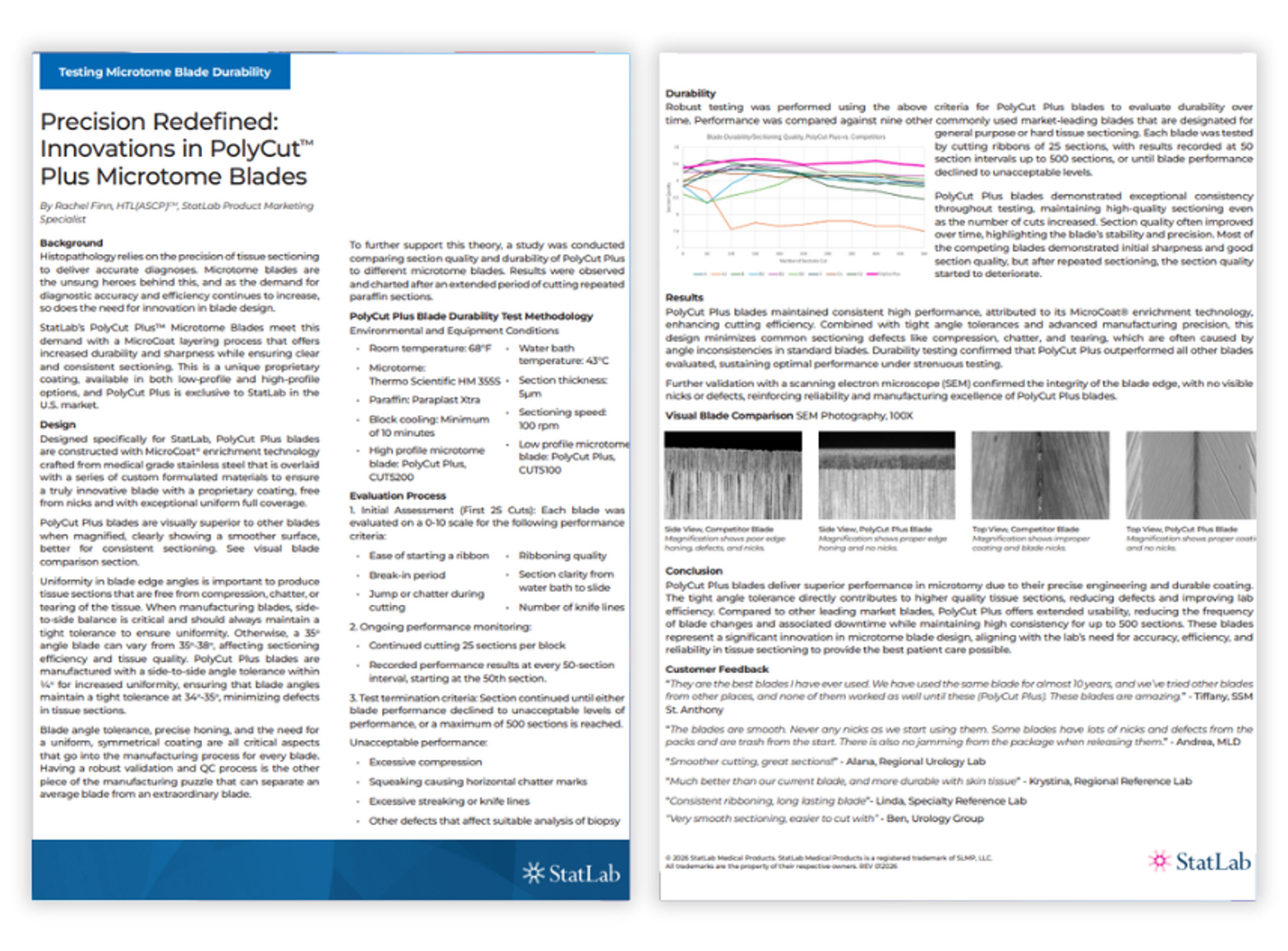

White Papers

Innovations in PolyCut Plus microtome blades

White Papers

Automated food-flavour analysis using SIFT-MS

Application Notes