Product Brochures

Resources

25

Product Brochures

The special one: AIA-360 immunoassay analyzer

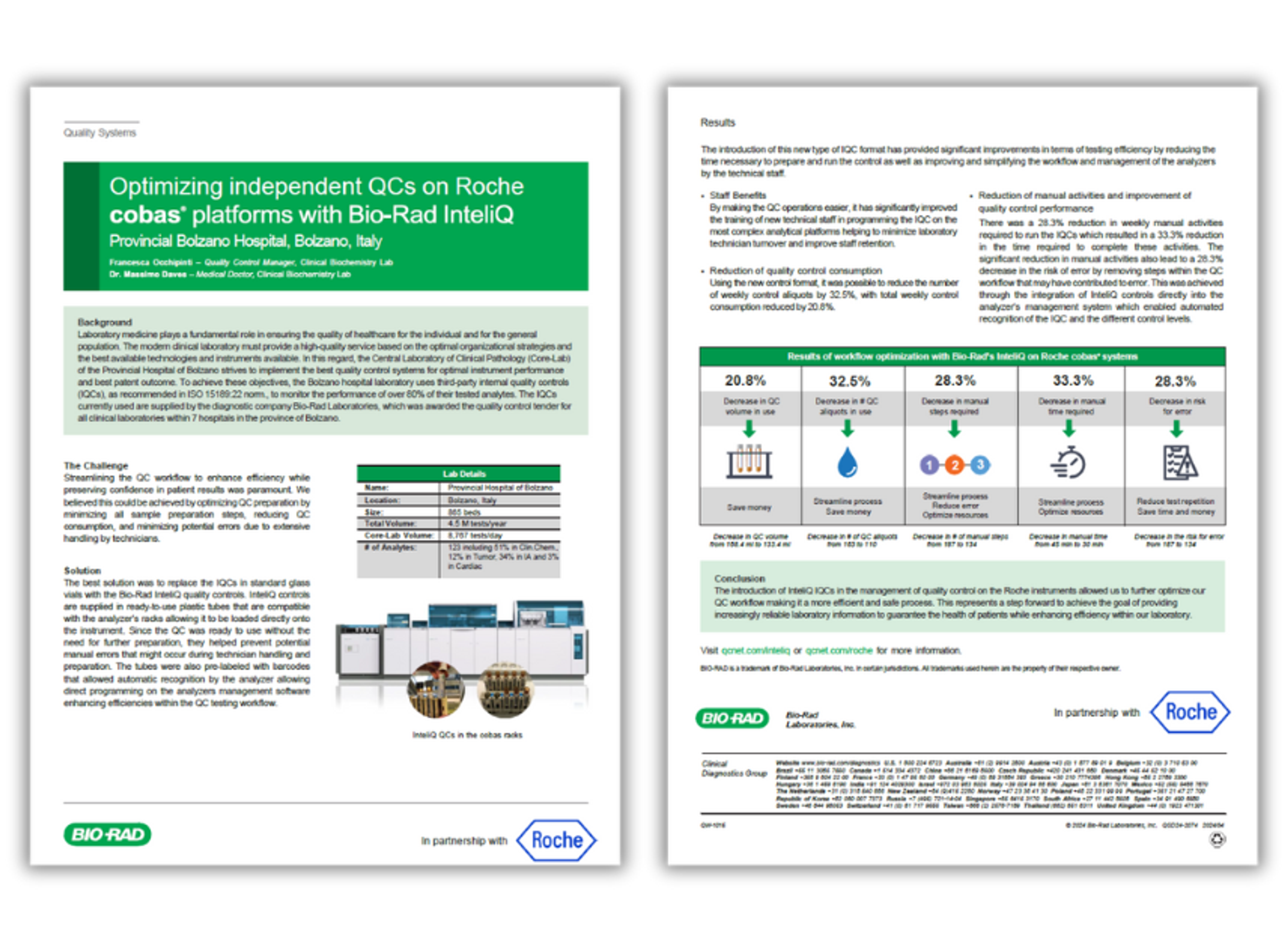

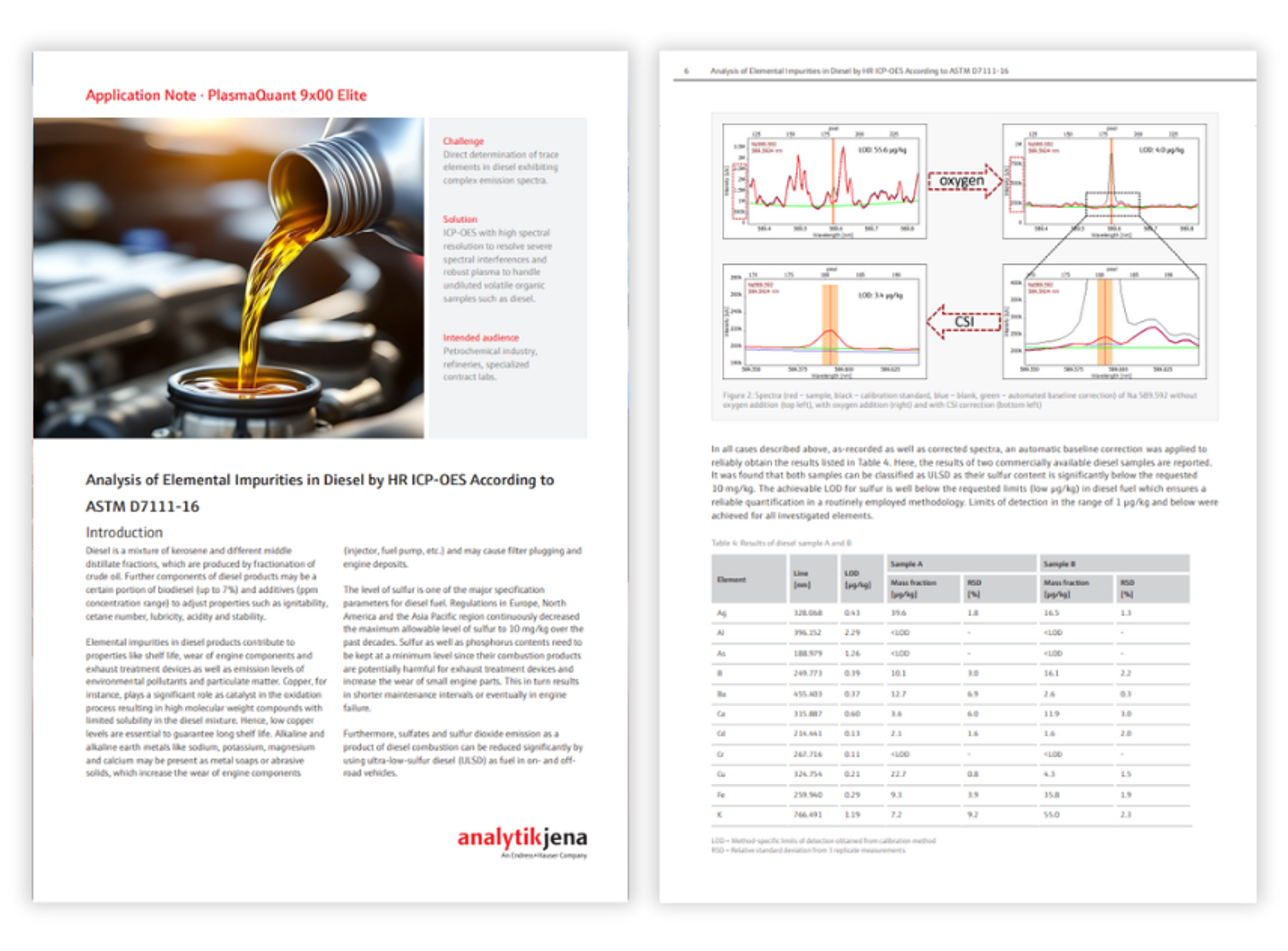

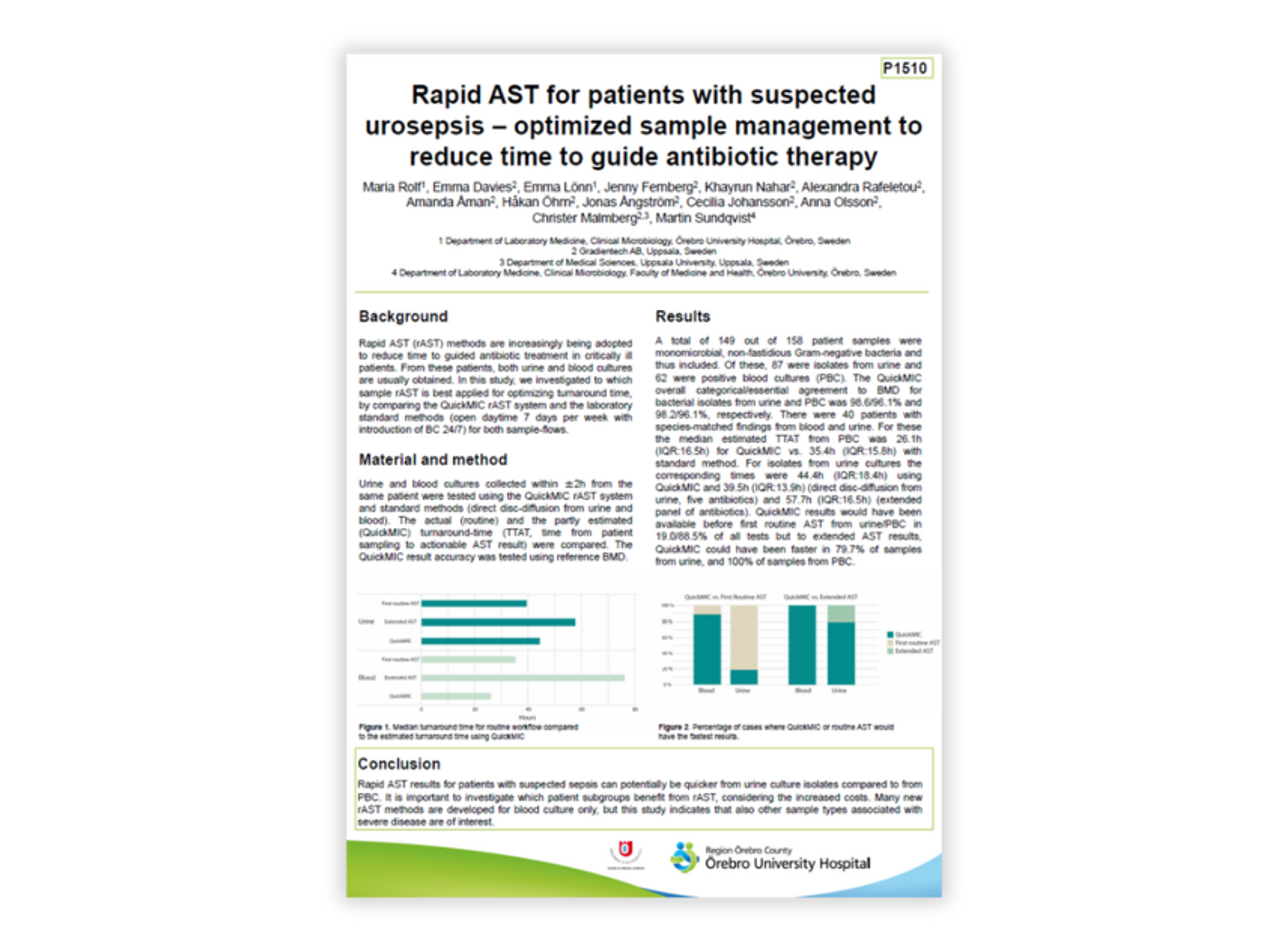

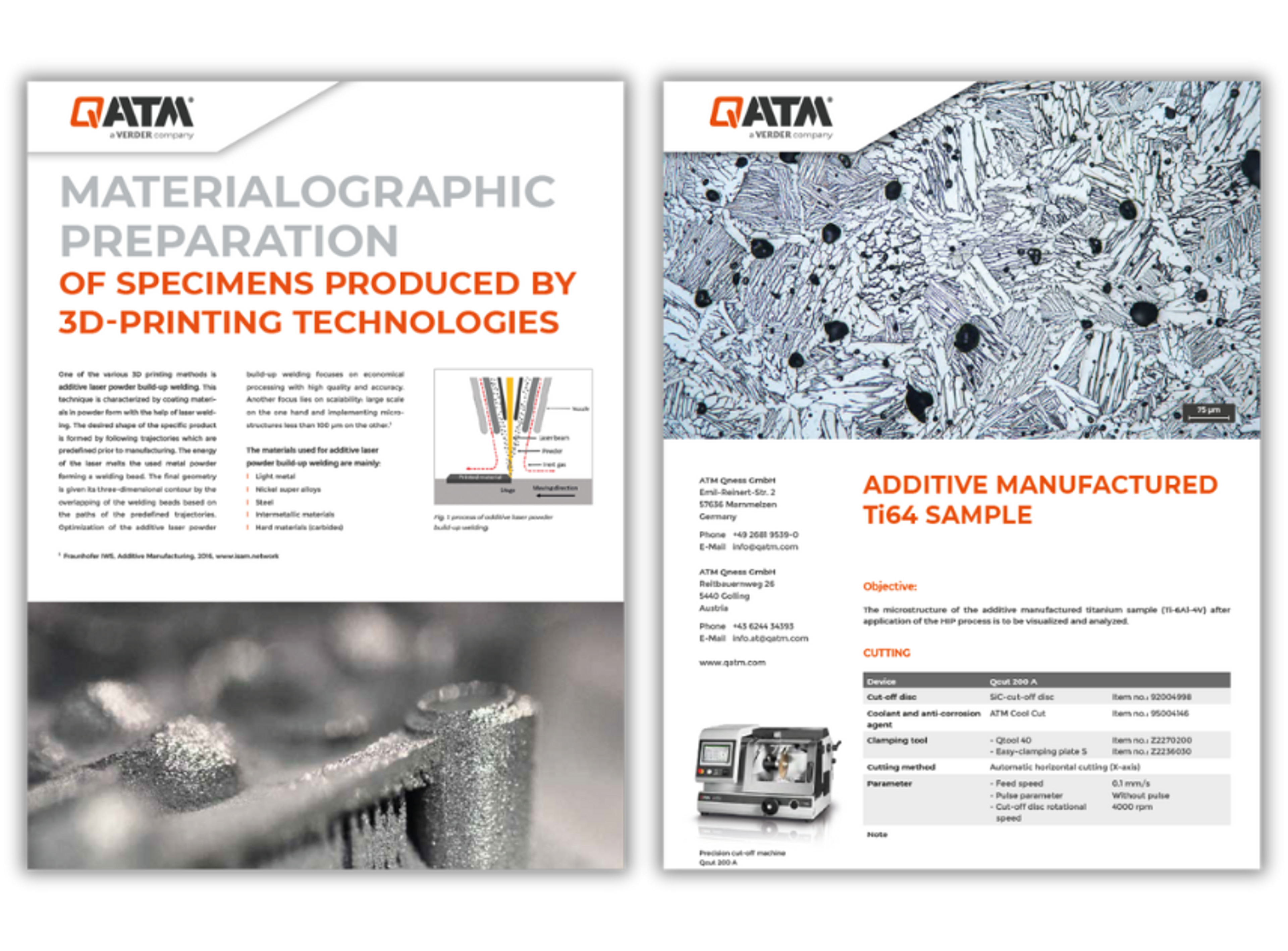

Application Notes

Freeze-drying illustrated laboratory guide

Application eBooks

Miniaturize to maximize: Precision liquid handling & dispensing for discovery and applied research

Essential techniques for PCR, mass spec sample prep, direct titration, assay development, and more

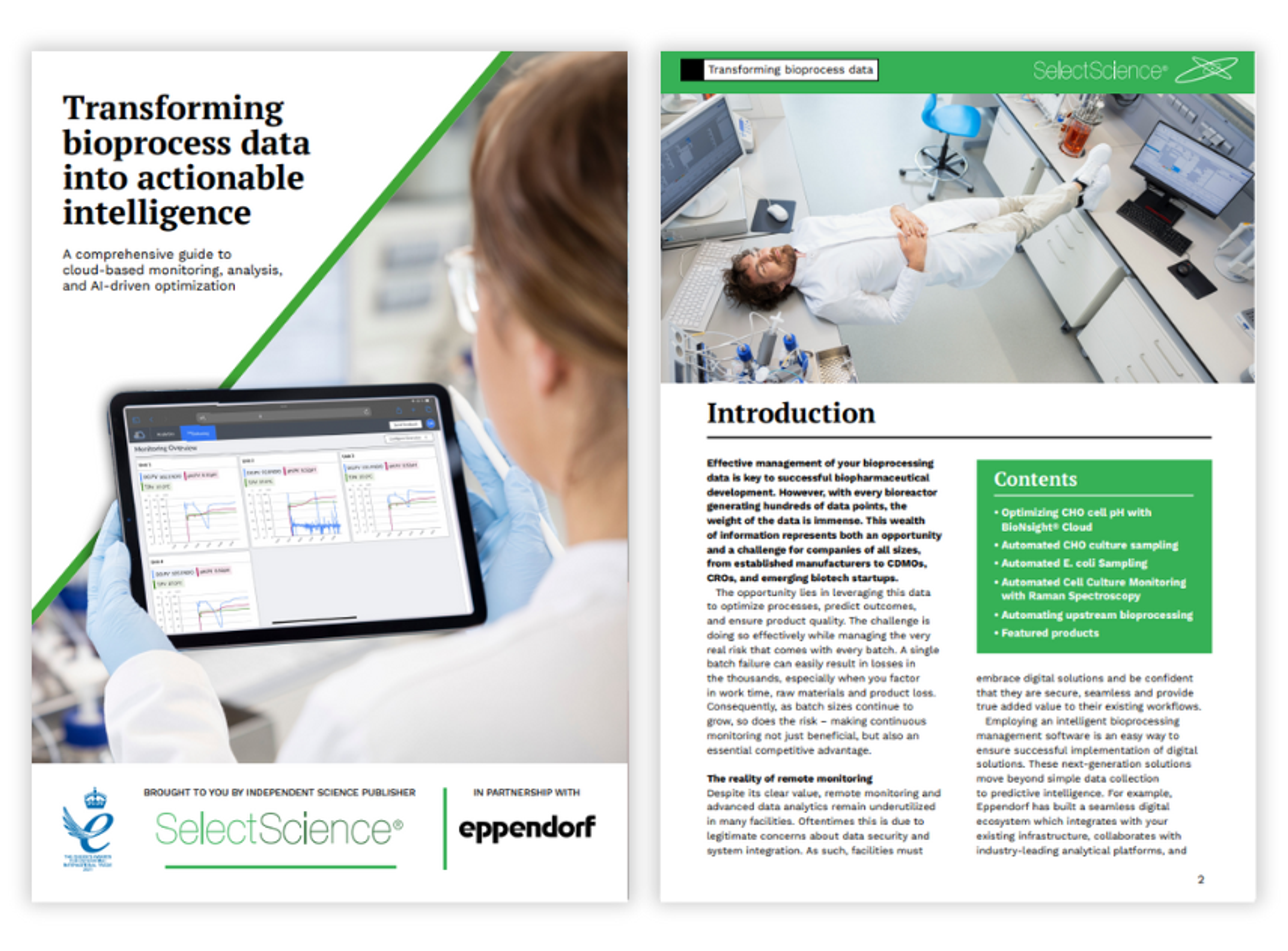

Application eBooks

Transforming bioprocess data into actionable intelligence

Product Brochures

The compact HbA1c analyzer with big impact

Application eBooks

Streamline liquid handling with automation

Product Brochures

Introducing the Omnia Discovery

Application Notes

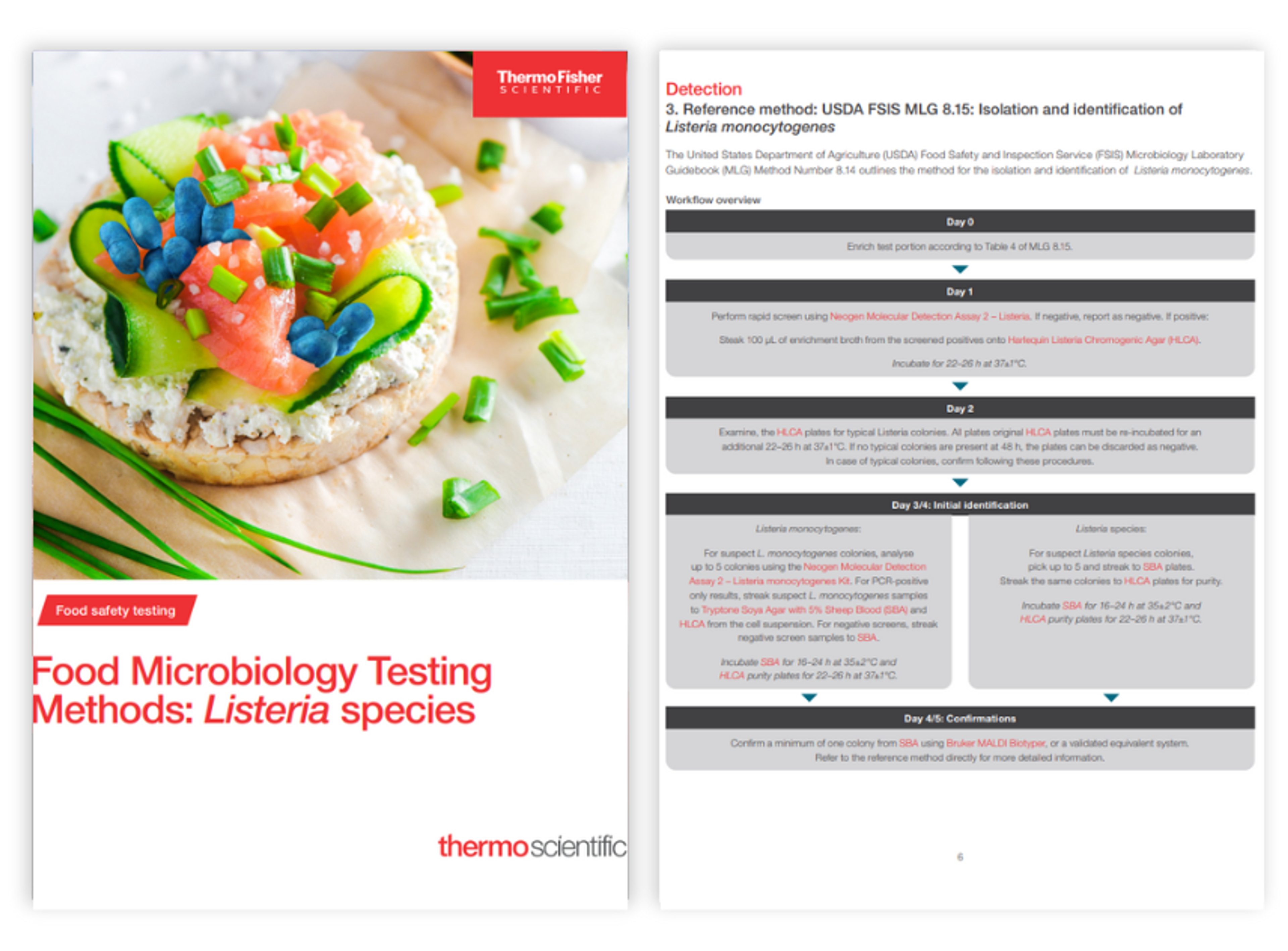

Food microbiology testing methods for Listeria species

Application Notes

NanoDrop Ultra Acclaro Pro performance data

Application Notes

Rapid electrochemical assessment of paint

Product Brochures

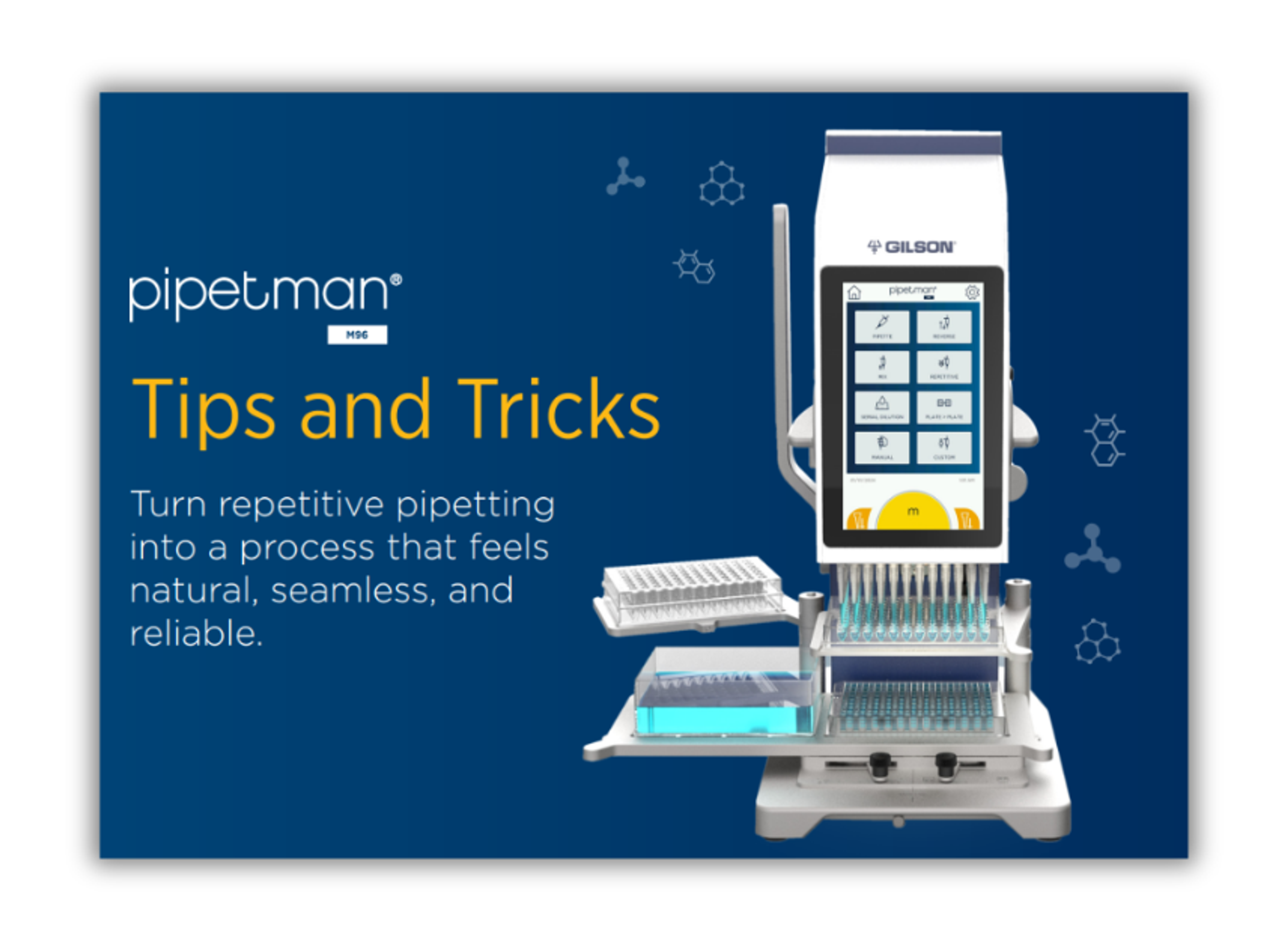

Pipetman M96: Tips and tricks

Product Brochures

LICORbio Atlas Imaging System

Product Brochures