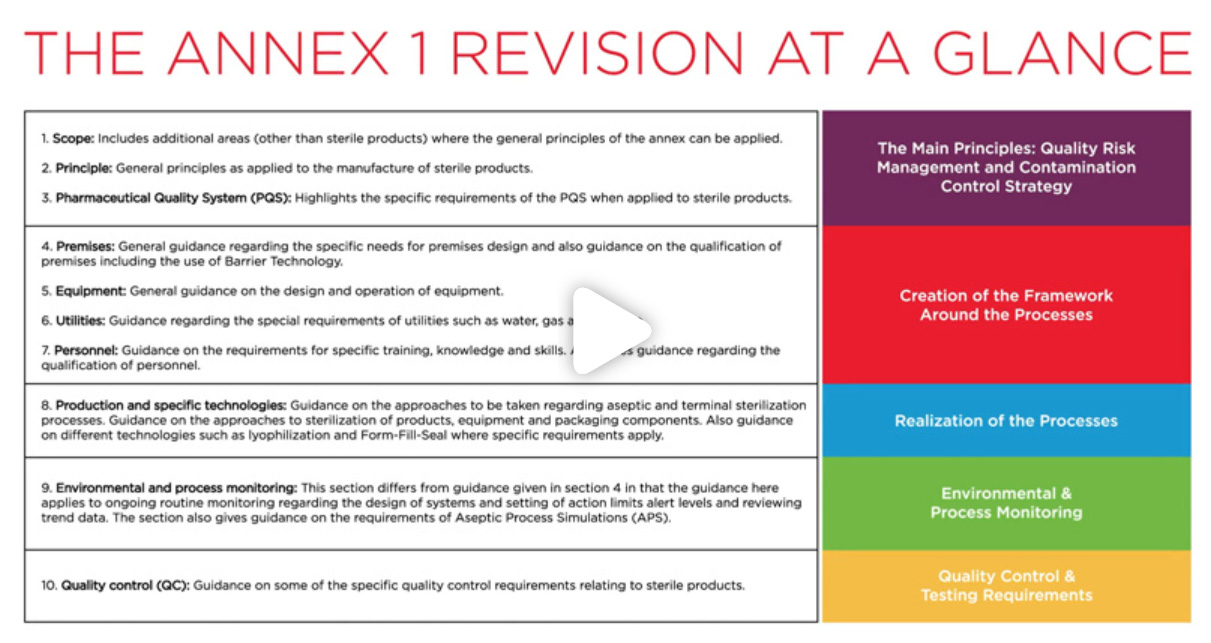

CCS has emerged as a new and crucial concept underscored in the latest

revision of Annex 1 in 2022, reflecting its significance with 52 mentions throughout the

guidance.

It is a concept that expands beyond the manufacture of sterile products to encompass

design of premises, cleanroom classification, qualification, validation, monitoring and personnel

gowning. Moreover, it serves as a supportive framework for the production of non-sterile

products.

A notable statement on page 5 of Annex 1 highlights the pivotal role of senior management

in ensuring effective oversight of control measures throughout the facility and product lifecycle.

Within this context, the mention of CCS occurs nine times within Section 2 and a

total of 52 times throughout the entire document, reflecting its heightened importance. This increased

emphasis on CCS and QRM underscores the growing recognition of their pivotal role in ensuring product

quality, safety, and compliance with regulatory standards.

The evolution of these guidelines underscores a significant shift from the

previous absence of developed principles in 2008. The updated guidelines now dedicate Section 2 to

articulate detailed expectations and areas of consideration. It emphasizes the imperative for managing

processes, equipment, facilities, and manufacturing activities in accordance with QRM principles.